Preparation method for cyclohexane ethylene homopolymer or copolymer and catalyst

A technology for styrene homopolymers and styrene copolymers, which is applied in the preparation of homopolymers or copolymers of cyclohexylethylene and the field of catalysts, and can solve problems such as difficult separation of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

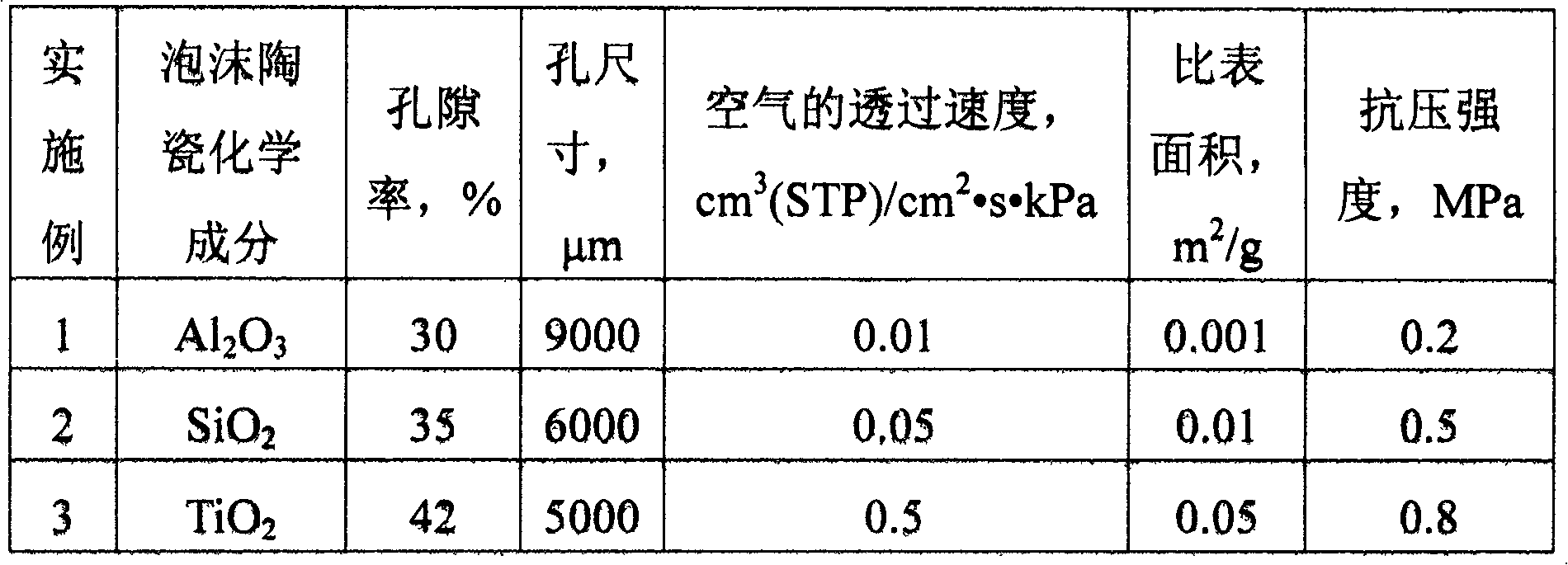

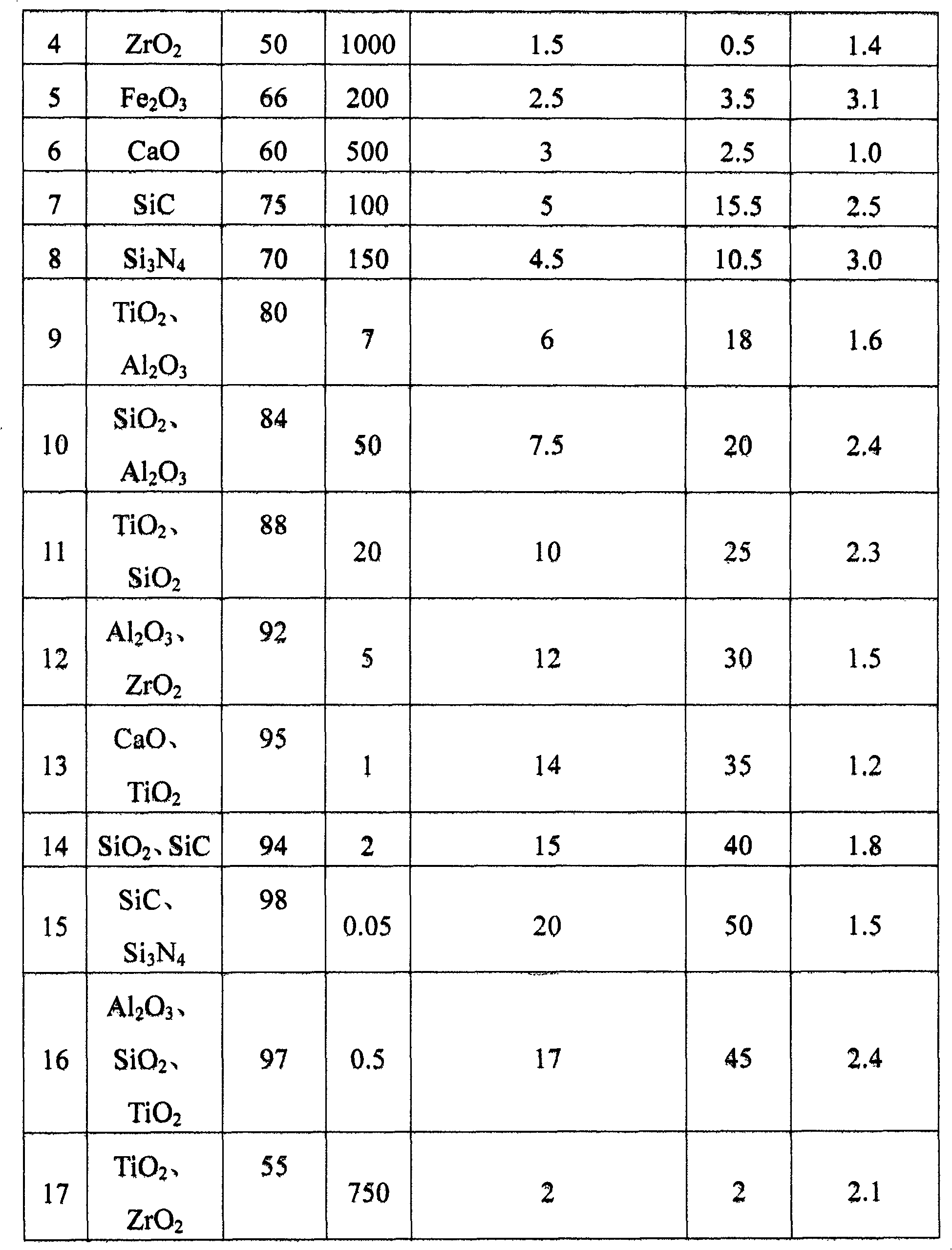

Examples

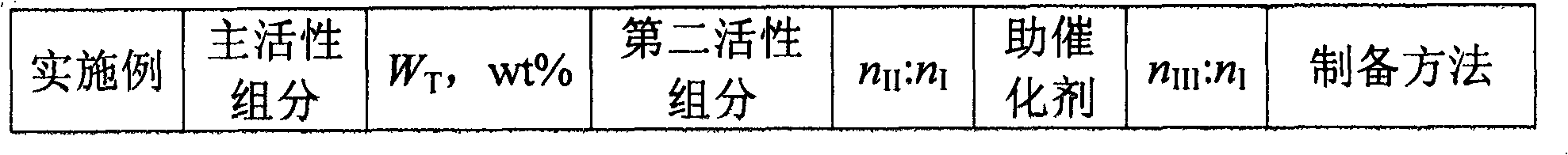

Embodiment 1

[0060] Adopt equal impregnation method to prepare catalyzer, be carrier by the ceramic foam in embodiment 1 in table 2, prepare the nitrate solution of main active component, second active component, procatalyst component by the first group formula in table 3 50g of foamed ceramics was immersed in the above solution for 12 hours, dried at 120°C after impregnation, and finally treated at 600°C for 2 hours under the action of hydrogen reducing agent to obtain supported foamed ceramics catalyst.

Embodiment 2

[0062] Adopt excessive impregnation method to prepare catalyzer, be carrier by the ceramic foam in embodiment 2 in table 2, prepare the hydrochloride solution of main active component, second active component, procatalyst component by the second group formula in table 3 , immerse 50g of foamed ceramics into the above solution for 4 hours, dry at 120°C after immersion, and finally treat at 500°C for 3 hours under the action of a hydrogen reducing agent to obtain a supported foamed ceramic catalyst .

Embodiment 3

[0064] Adopt equal impregnation method to prepare catalyzer, be carrier by ceramic foam in embodiment 3 in table 2, prepare the nitrate solution of main active component, second active component, procatalyst component by the third group of formulas in table 3, Immerse 50g of foamed ceramics into the above solution for 6 hours, dry at 120°C after the impregnation, and finally treat at 200°C for 6 hours under the action of a formaldehyde reducing agent to obtain a supported foamed ceramic catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com