Equipment for measuring temperature of steel coil in top hat annealing furnace and using method of equipment

A bell-type annealing furnace and temperature measuring device technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve problems such as unreasonable structure and shape, affect the surface quality of strip steel, and reduce the yield of finished products, so as to reduce folding and Scratch, low cost, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

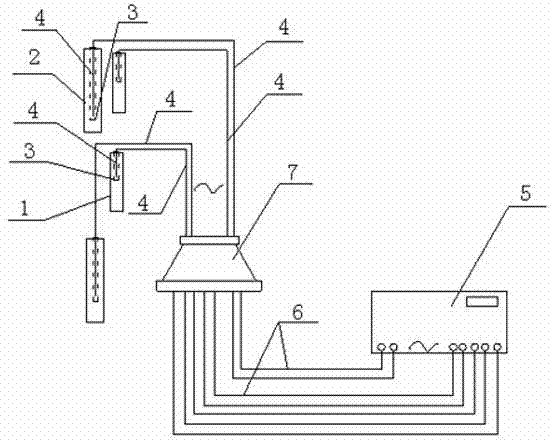

[0031] A method for using a temperature measuring device for steel coils in a bell annealing furnace, the steps of which are:

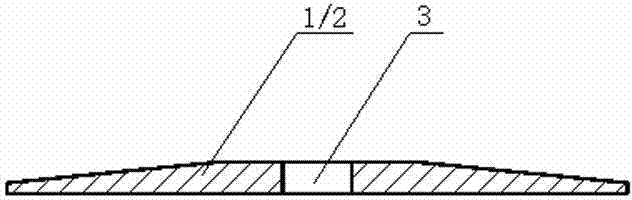

[0032] 1) According to the temperature measurement point set for the steel coil, during the strip coiling process, insert a core insert 2 into the place where the thermocouple 4 of the steel coil is not damaged by pressure, and make the outer surface of the core insert 2 Towards the outer normal line of the steel coil; the depth of inserting the core insert 2 into the steel coil is half of the width of the steel coil, and the measured width of the steel coil is 1000 mm, so the depth of inserting the core insert 2 into the steel coil at 500 mm;

[0033] 2) As the diameter of the steel coil increases, according to the temperature measurement point set for the edge of the steel coil, insert an edge insert 1 into the place where the thermocouple 4 of the steel coil is not damaged by pressure, and make the edge insert The outer surface of 1 faces the oute...

Embodiment 2

[0039] A method for using a temperature measuring device for steel coils in a bell annealing furnace, the steps of which are:

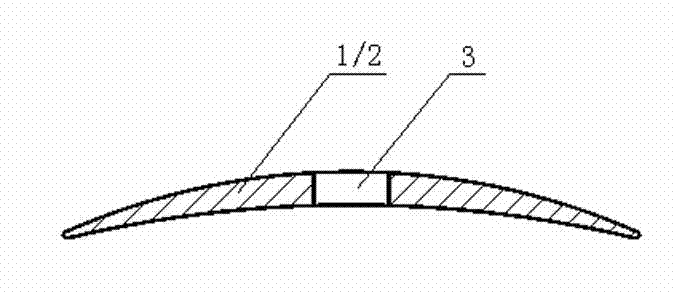

[0040] 1) According to the temperature measurement point set for the steel coil, during the coiling process of the steel strip, insert the two core inserts 2 into the place where the thermocouple 4 of the steel coil will not be damaged by pressure, and make the outer core insert 2 The side faces the outer normal of the steel coil; the depth of one of the core inserts 2 inserted into the steel coil is two-thirds of the width of the steel coil, and the measured width of the steel coil is 1020 mm, so the core insert 2 is inserted into the steel coil. The depth of the coil is 680 mm; the depth of another core insert 2 inserted into the steel coil is 1 / 2 of the width of the steel coil, so the depth of the core insert 2 inserted into the steel coil is 510 mm;

[0041] 2) As the diameter of the steel coil increases, according to the temperature measurement p...

Embodiment 3

[0047] A method for using a temperature measuring device for steel coils in a bell annealing furnace, the steps of which are:

[0048] 1) According to the temperature measurement point set for the steel coil, during the coiling process of the steel strip, insert the two core inserts 2 into the place where the thermocouple 4 of the steel coil will not be damaged by pressure, and make the outer core insert 2 The side faces the outer normal of the steel coil; the depth of one of the core inserts 2 inserted into the steel coil is three-quarters of the width of the steel coil, and the measured width of the steel coil is 1050 mm, so the core insert 2 is inserted into the steel coil. The depth of the coil is 788 mm; the depth of another core insert 2 inserted into the steel coil is 2 / 3 of the width of the steel coil, so the depth of the core insert 2 inserted into the steel coil is 700 mm;

[0049] 2) As the diameter of the steel coil increases, according to the temperature measureme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com