Steel for caterpillar type engineering machinery caterpillar link pin bushes and production method thereof

A construction machinery, crawler-type technology, applied in the field of metallurgy, to achieve stable recovery rate, avoid secondary pollution, high wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

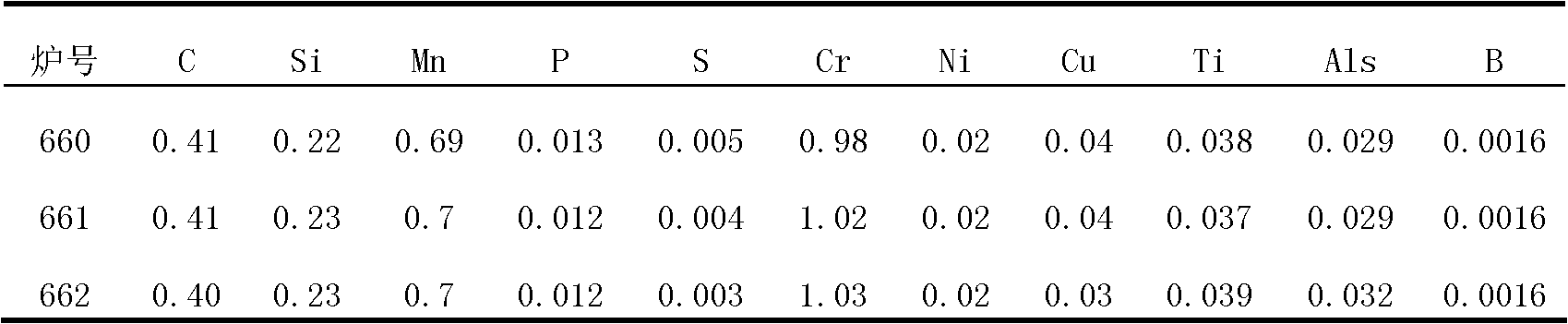

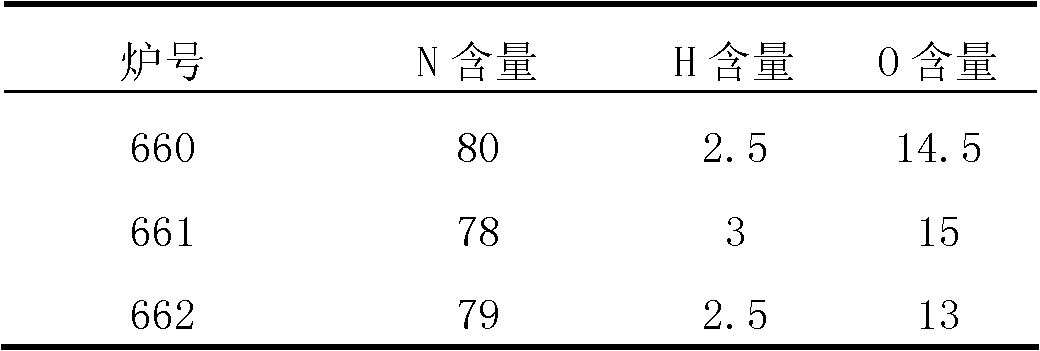

[0039] How the present invention is implemented is specifically illustrated with the production process of Φ70mm specification steel.

[0040] The specific process steps are:

[0041] (1) Smelting and alloying, adding molten iron, smelting in an electric furnace, tapping, refining outside the furnace, and vacuum degassing. The smelting control of deoxidation and degassing of steel is strengthened by blowing argon in the ladle and vacuum degassing treatment, the final deoxidation is fed to the aluminum wire, and B iron is added before the vacuum degassing treatment to ensure that the chemical composition meets the requirements, and the oxygen content in the steel is not more than 20×10 -6 .

[0042] (2) Continuous casting, control the degree of superheat, the degree of superheat of the continuous casting tundish is 15-30°C, and control the casting speed of continuous casting to be 0.55-1.00m / min.

[0043] (3) Rolling, the soaking temperature of the billet in the heating furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com