Substrate heating device

A heating device and substrate technology, applied in ion implantation plating, gaseous chemical plating, coating and other directions, can solve the problems of uneven temperature and long time, and achieve the advantages of improving heating uniformity, low cost and avoiding pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

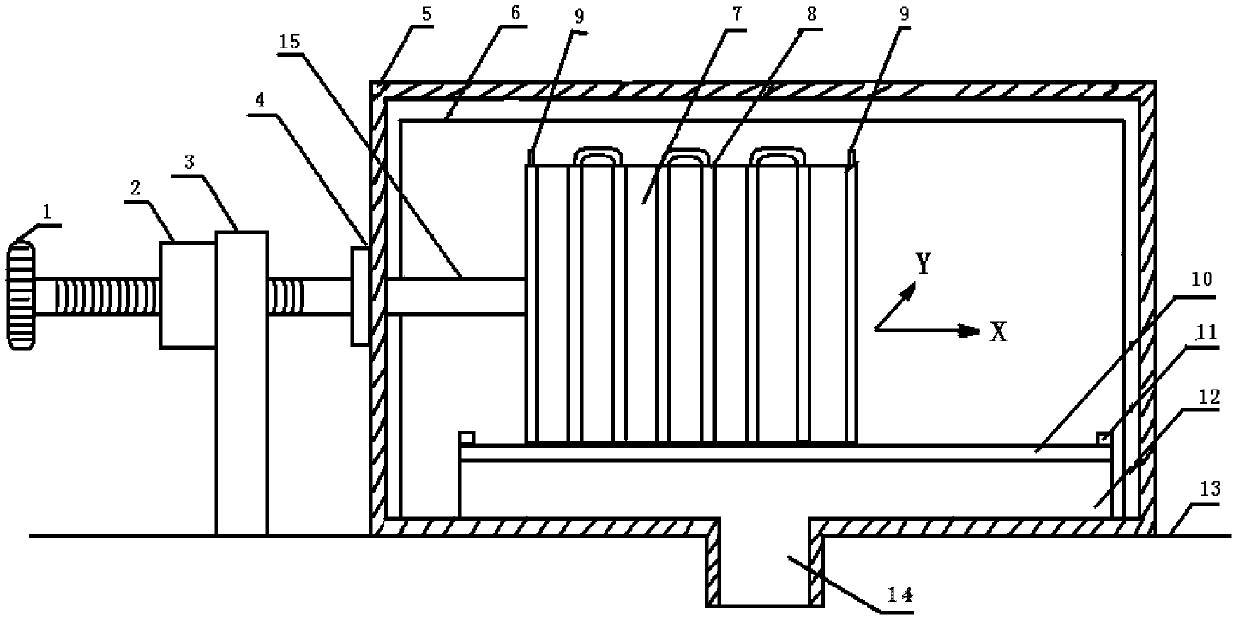

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

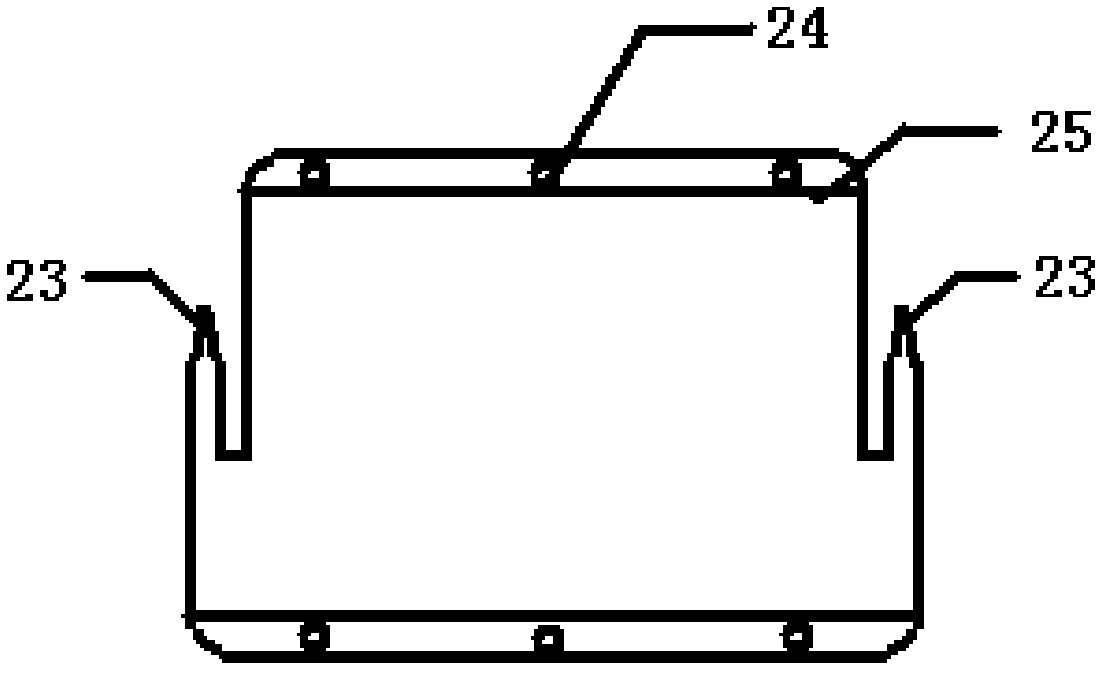

[0032] The substrate heating device of the present invention mainly includes a box body and a substrate carrier heating frame.

[0033] The shape of the box body is a square box, and its material is stainless steel.

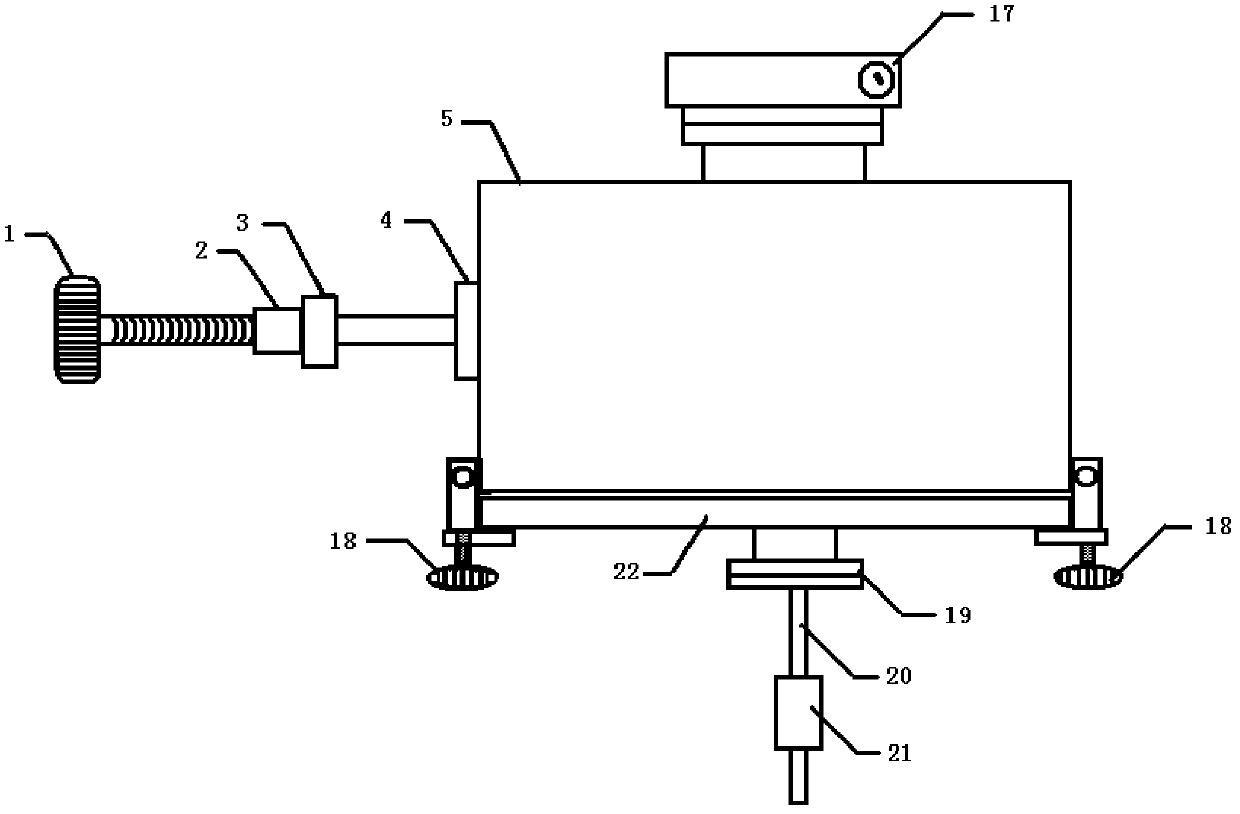

[0034] Such as figure 1 , 2 As shown, a vacuum-tight door 22 for loading and unloading the substrate carrier is opened on a vertical surface of the box body, and an observation window 19 is provided on the vacuum-tight door 22 for observing the internal conditions of the heating device; the observation window 19 A magnetic force push rod 20 is housed in the below, and a magnetic steel 21 is housed on the magnetic force push rod 20; A substrate outlet vacuum valve 17 is installed on the other side of the box opposite to the vacuum-tight door 22 . A manual rotating handle 1 is installed on the vertical surface of the described c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com