Colorful fiber

A fiber, monofilament fiber technology, applied in the direction of conjugated synthetic polymer rayon, textiles and papermaking, adding pigments in spinning solution, etc. achieve high softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

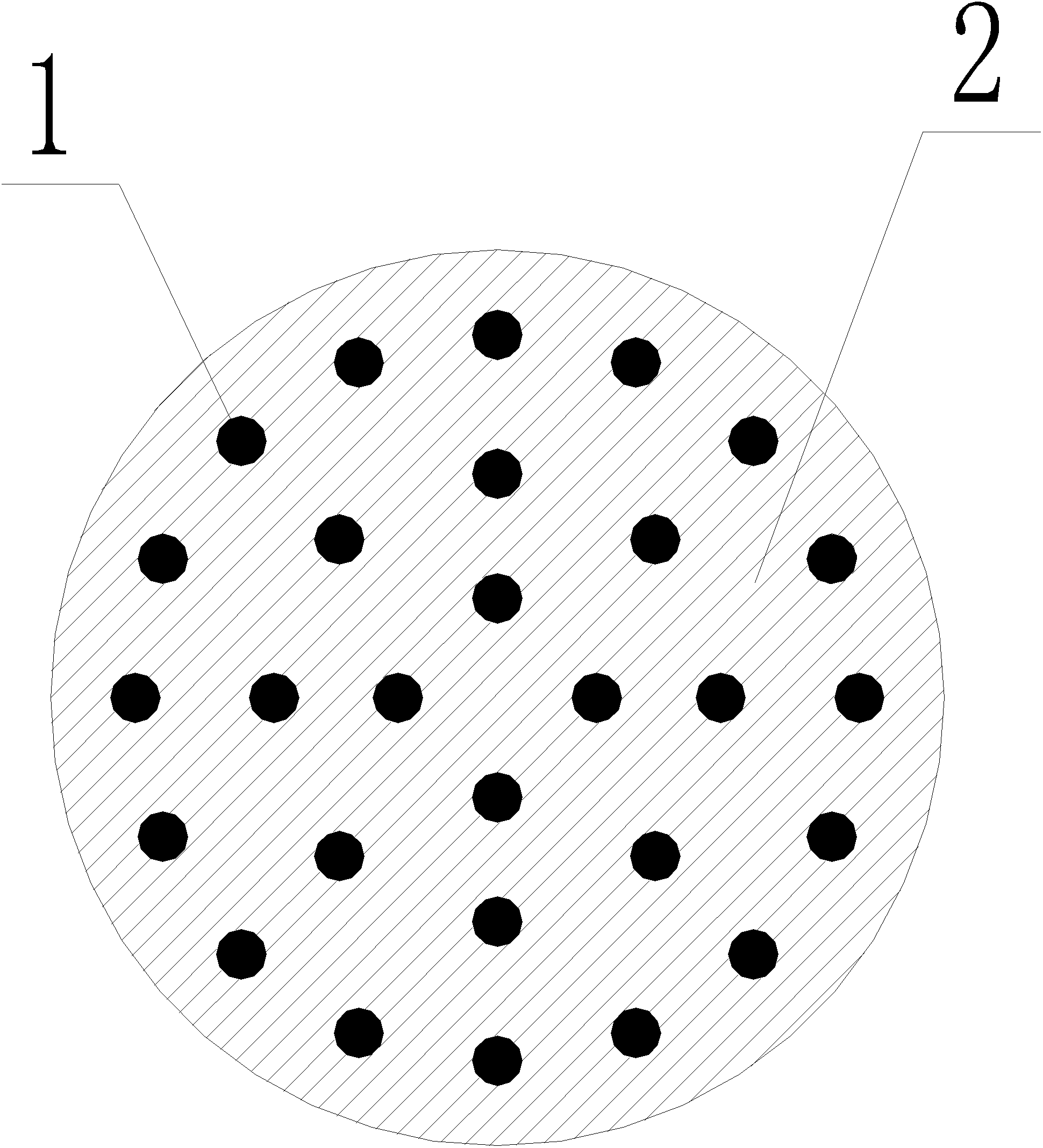

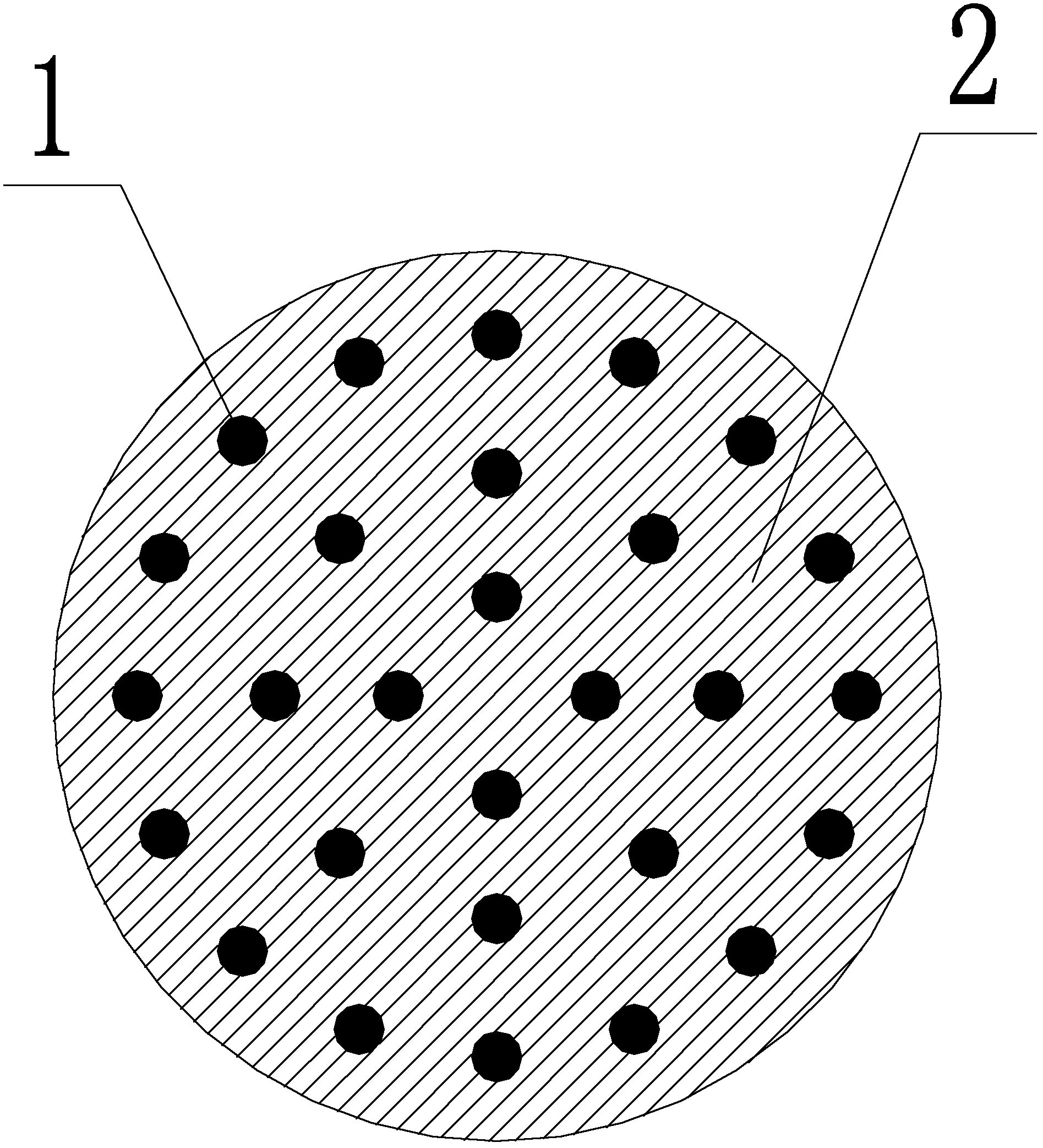

Image

Examples

Embodiment approach 1

[0010] Embodiment 1: (1) take common PBT chips and single-color masterbatches accounting for 70% of the total weight as the first raw materials, common PBT chips enter the material continuous drying tower, and make conventional PBT dry chips with a moisture content of <100ppm, and at the same time The monochrome masterbatch is accurately metered and extruded by the masterbatch injector, and enters the first screw extruder at the same time as the conventional PBT dry chips, melted and extruded into a monochrome PBT melt A that can be spun, and the first screw extruder The melt extrusion process is equipped with 3 to 5 heating zones, the heating temperature of each zone is 255°C, 265°C, 275°C, 275°C, 275°C (five zone screw), and the monochromatic PBT melt A is transported to In the spinning box (the monochromatic PBT melt A passes through the pre-filter between the first screw extruder and the spinning box, the large particle impurities in the monochromatic PBT melt A are removed...

Embodiment approach 2

[0014] Embodiment two: (1) take common PBT chip and monochromatic color masterbatch that account for 80% of total weight as first raw material, common PBT chip enters material continuous drying tower, makes the conventional PBT dry chip of moisture content<100ppm, simultaneously The monochrome masterbatch is accurately metered and extruded by the masterbatch injector, and enters the first screw extruder at the same time as the conventional PBT dry chips, melted and extruded into a monochrome PBT melt A that can be spun, and the first screw extruder The melt extrusion process is equipped with 3 to 5 heating zones, the heating temperature of each zone is 255°C, 265°C, 275°C, 275°C, 275°C (five zone screw), and the monochromatic PBT melt A is transported to In the spinning box (the monochromatic PBT melt A passes through the pre-filter between the first screw extruder and the spinning box, the large particle impurities in the monochromatic PBT melt A are removed), and further even...

Embodiment 3

[0018] Embodiment three: take common PBT chips and single-color masterbatches accounting for 60% of the total weight as the first raw material, and water-soluble chips with an amount of 40% by weight as the second raw material, and the rest of the working process is the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com