Prestress reinforced boom, prestress reinforced support leg and pump truck

A pre-tightening force and boom technology, applied in vehicle maintenance, transportation and packaging, lifting vehicle accessories, etc., can solve the problems of difficult manufacturing, inflexible movements, heavy weight, etc., to reduce costs and manufacturing difficulties, reduce Production cost, the effect of improving stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

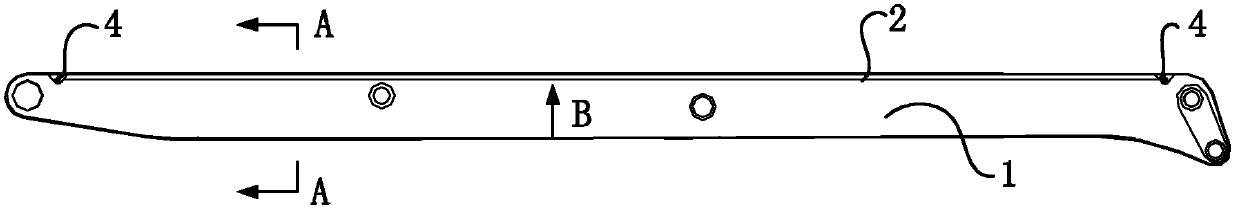

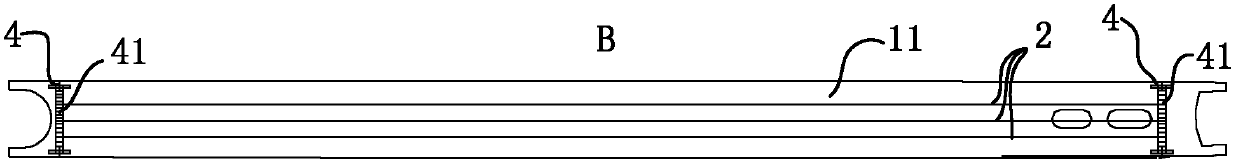

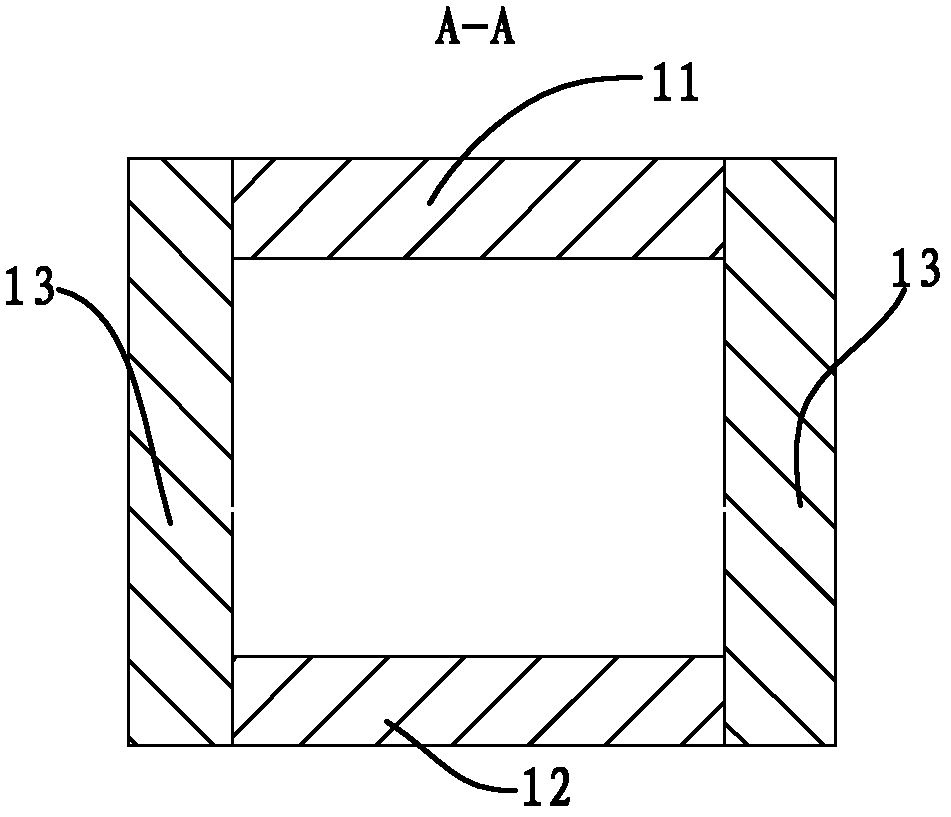

[0116] Such as figure 1 , figure 2 and image 3 As shown, two fixing seats 4 are respectively arranged at the two ends below the upper plate 11 of the jib body 1, and the cable 2 is arranged between the two fixing seats 4, and a certain preload is set when the cable 2 is installed. force.

[0117] Two supporting shafts 41 are respectively arranged on the two fixing bases 4 , and the drag cable 2 is arranged on the two supporting shafts 41 .

Embodiment 2

[0119] Such as Figure 4 , Figure 5 and image 3 As shown, two fixing seats 4 are respectively arranged at the two ends above the upper plate 11 of the jib body 1, and the cable 2 is arranged between the two fixing seats 4, and a certain pre-tightening force is set when the cable 2 is installed. , and a tensioning device 3 is also provided on the cable 2, which can easily adjust the pre-tightening force on the cable 2.

[0120] Supporting shafts 41 are respectively arranged on the two fixing bases 4 , and the drag cables 2 are arranged on the two supporting shafts 41 .

Embodiment 3

[0122] Such as Figure 7 and image 3 As shown, two fixing seats 4 are respectively provided at both ends of the inner surface of the side plate 13 of the jib body 1, and the cable 2 is arranged between the two fixing seats 4, and passes through the upper plate 11, and is installed A certain pre-tightening force is set during the dragline 2, and a tensioning device 3 is arranged on the dragline 2, so that the pre-tightening force on the dragline 2 can be adjusted conveniently. The tensioning device 3 is as Figure 6 Screw tensioner shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com