Wood-plastic co-extruded section for doors and windows

A technology of door and window profiles and wood-plastic profiles, applied in windows/doors, building components, buildings, etc., can solve the problems of high cost and achieve the effects of unfailing performance, good weather resistance, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

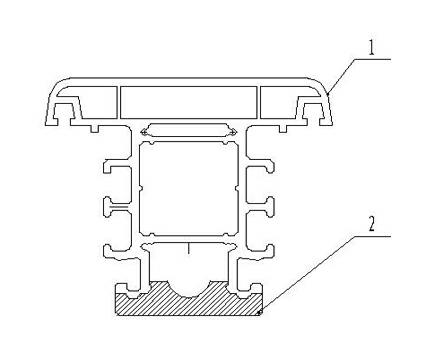

[0035] The invention is a wood-plastic co-extruded door and window profile, such as figure 1 As shown, it includes PVC-U plastic profile 1 and wood-plastic profile 2, which is a wood-plastic co-extrusion profile composed of PVC-U plastic profile 1 and wood-plastic profile 2; it is the combination of wood-plastic profile raw materials and PVC-U After the raw materials of the plastic profiles are dried at 70°C by the dryer, the raw materials are sent to the wood-plastic extruder and the PVC-U profile extruder respectively, and the initial temperature of each extruder is 110°C. , after reaching the metering section of the main engine, melt and plasticize at a temperature of 175°C, and then input the materials extruded synchronously by two plastic extruders into a composite co-extruded profile forming mold at 175°C It is formed at a temperature of ℃, and then vacuum-formed in a vacuum setting mold, then water-cooled and formed in a vacuum water tank at 5°C to 15°C, and then made b...

Embodiment 2

[0039] The invention is a wood-plastic co-extruded door and window profile, such as figure 1 As shown, it includes PVC-U plastic profile 1 and wood-plastic profile 2, which is a wood-plastic co-extrusion profile composed of PVC-U plastic profile 1 and wood-plastic profile 2; it is the combination of wood-plastic profile raw materials and PVC-U After the raw materials of the plastic profiles are dried at 75°C by the dryer, the raw materials are sent to the wood-plastic extruder and the PVC-U profile extruder respectively, and the initial temperature of each extruder is 115°C. , after arriving at the metering section of the main engine, it is melted and plasticized at a temperature of 178°C, and then the materials extruded synchronously by two plastic extruders are input into a composite co-extrusion profile forming mold, It is formed under high temperature, and then vacuum formed in the shaping mold, and then water-cooled and formed in a vacuum water tank at 10°C, and then it i...

Embodiment 3

[0041] The invention is a wood-plastic co-extruded door and window profile, such as figure 1 As shown, it includes PVC-U plastic profile 1 and wood-plastic profile 2, which is a wood-plastic co-extrusion profile composed of PVC-U plastic profile 1 and wood-plastic profile 2; it is the combination of wood-plastic profile raw materials and PVC-U The raw materials of the plastic profiles are dried at a temperature of 70°C to 80°C by the dryer, and then sent to the wood-plastic extruder and the PVC-U profile extruder respectively. The initial temperature of each extruder is 120°C. Heating step by step, after reaching the metering section of the host machine, melting and plasticizing at a temperature of 175 ° C ~ 180 ° C, and then the materials extruded synchronously by two plastic extruders in proportion are input to a composite co-extruded profile forming In the mold, it is formed at a temperature of 190°C, and then vacuum-formed in a vacuum setting mold, then water-cooled and fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com