Cam with changeable circle diameter

A circular diameter, cam technology, applied in valve details, engine components, fuel injection pumps, etc., can solve the problems of fuel waste, the output horsepower cannot reach the maximum, the output horsepower becomes larger, etc., and achieves good fuel-saving performance and manufacturing costs. Low, more fuel-efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

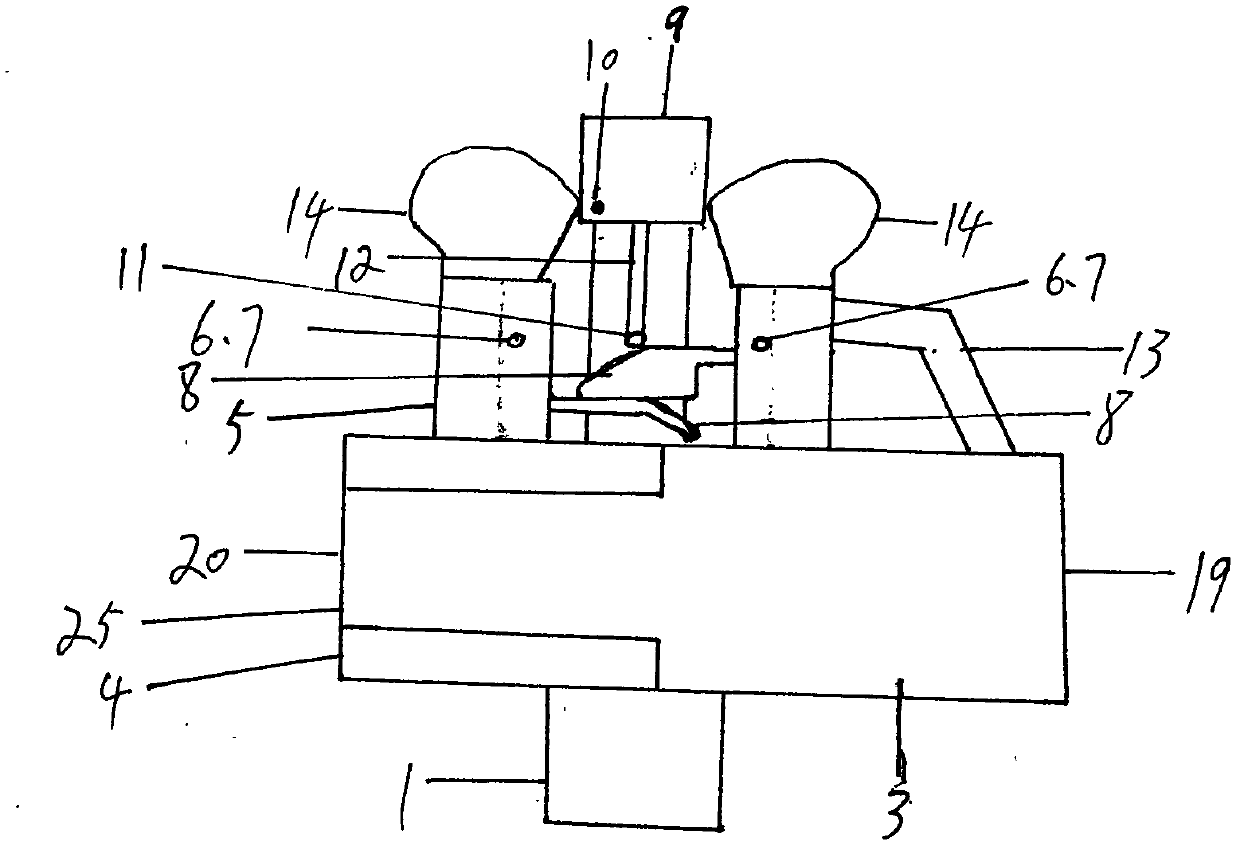

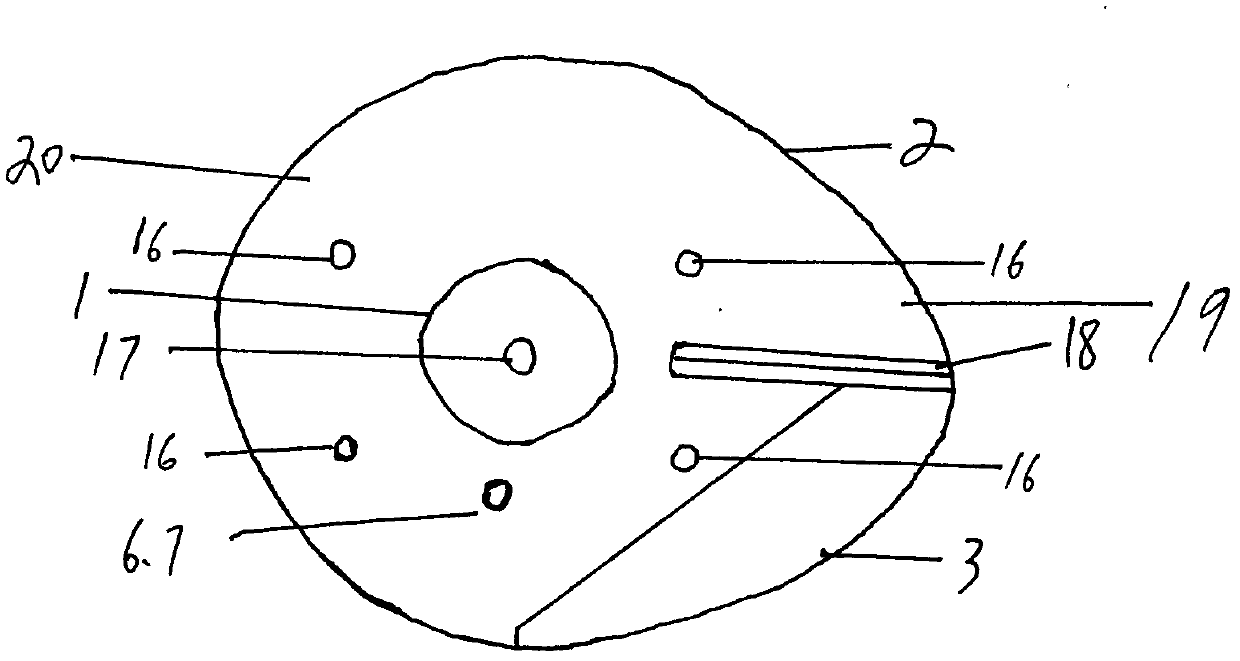

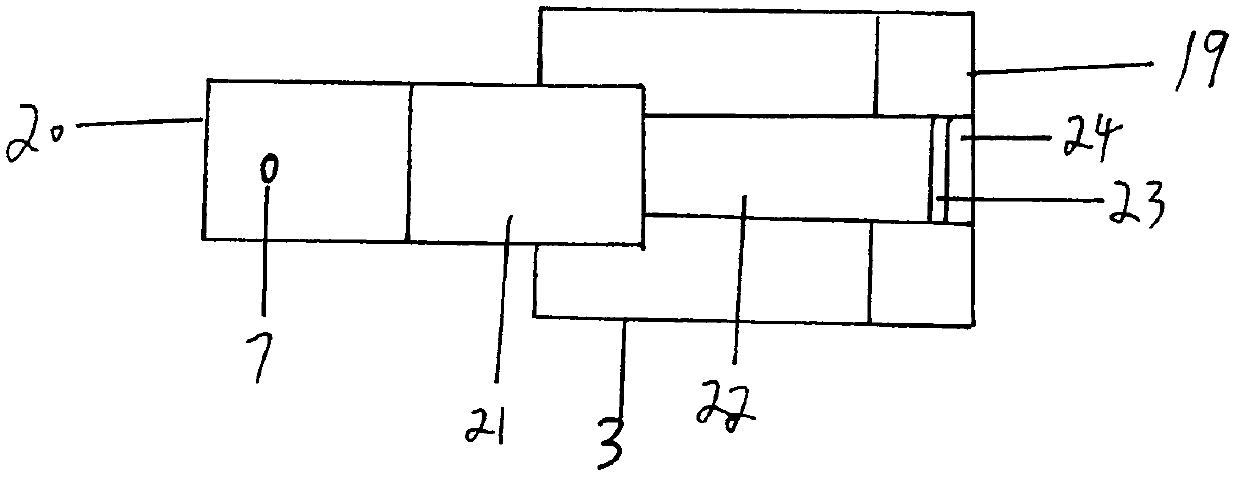

[0017] As shown in the figure, use the hole (7) on the fixed semicircular cam (2) to be sleeved on the camshaft (1), and the hole (16) and the hole (7) of the shaft seat post to be punched on the fixed semicircular cam (2) , open the hollow shaft hole (17) on the head of the camshaft (1), fix the hammer shaft seat hole (16) on the fixed semicircular cam (2) to fix the hammer shaft seat post (5), and hammer the shaft seat post (5) Perforate (7), install axle (6) in the hole (7), the hole that axle (6) string crosses hammering (14) and two hammer axle seat columns (5), one end of axle (6) is big, and one end is opened. The ring groove is inserted into the ring groove with a ring clip, and there is a shifting branch (8) inherent in the hammer (14). ) is strung across the hollow shaft (15) and the horizontal sleeve of the small spring on the inner surface, the small spring is in the large spring in the hollow shaft (15), the groove (12) is topped with a cover sleeve (9) on the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com