Optical freeform surface interference detection system

An interference detection, free technology, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of slow measurement methods, many error sources, unfavorable detection accuracy, etc., to overcome singleness and high cost, overcome large errors, Overcome the effect of high displacement accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

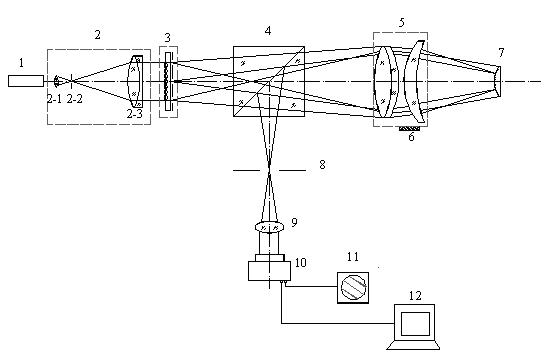

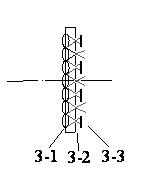

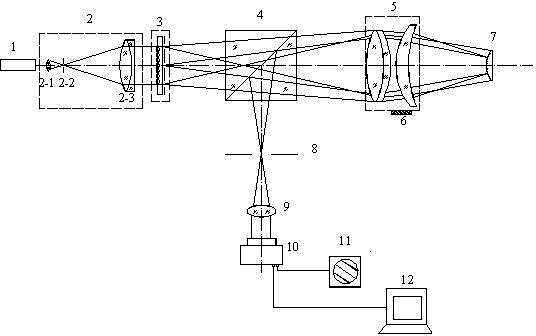

[0009] The optical free-form surface interference detection device of the present invention includes a laser 1, a beam expander system 2, a controllable microlens point source array 3, a beam splitting prism 4, a standard spherical lens group 5, a phase shifter 6, an aperture diaphragm 8, and an imaging lens 9. Charge coupled device CCD1, monitor 11 and computer 12; controllable microlens point source array 3 includes microlens array 3-1, pinhole array 3-2 and light source selection mask plate 3-3, controllable microlens The point source array 3 is located on the outgoing light path of the laser, and is used to generate the selected point light source. The microlens array 3-1 is followed by the pinhole array 3-2, and the light source selection mask plate 3-3 is placed behind the pinhole array 3-2; the array number of the microlens array 3-1, the pinhole array 3 The number of arrays of -2 and the number of arrays of the light source selection mask plate 3-3 are the same.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com