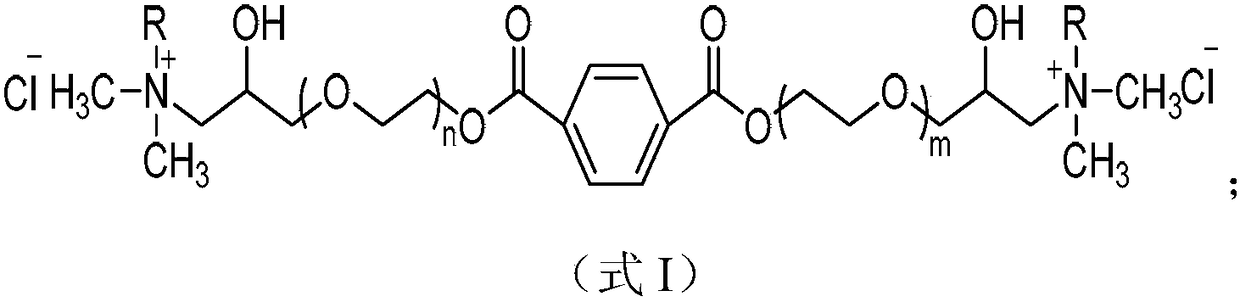

A kind of cationic polyester polyether block copolymer and its preparation method and application

A technology of block copolymer and polyester polyether, applied in the field of daily chemicals, can solve the problems of insufficient washing resistance, easy to be stained, easy to generate static electricity, etc. Hydrophilic and antistatic ability, the effect of increasing detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

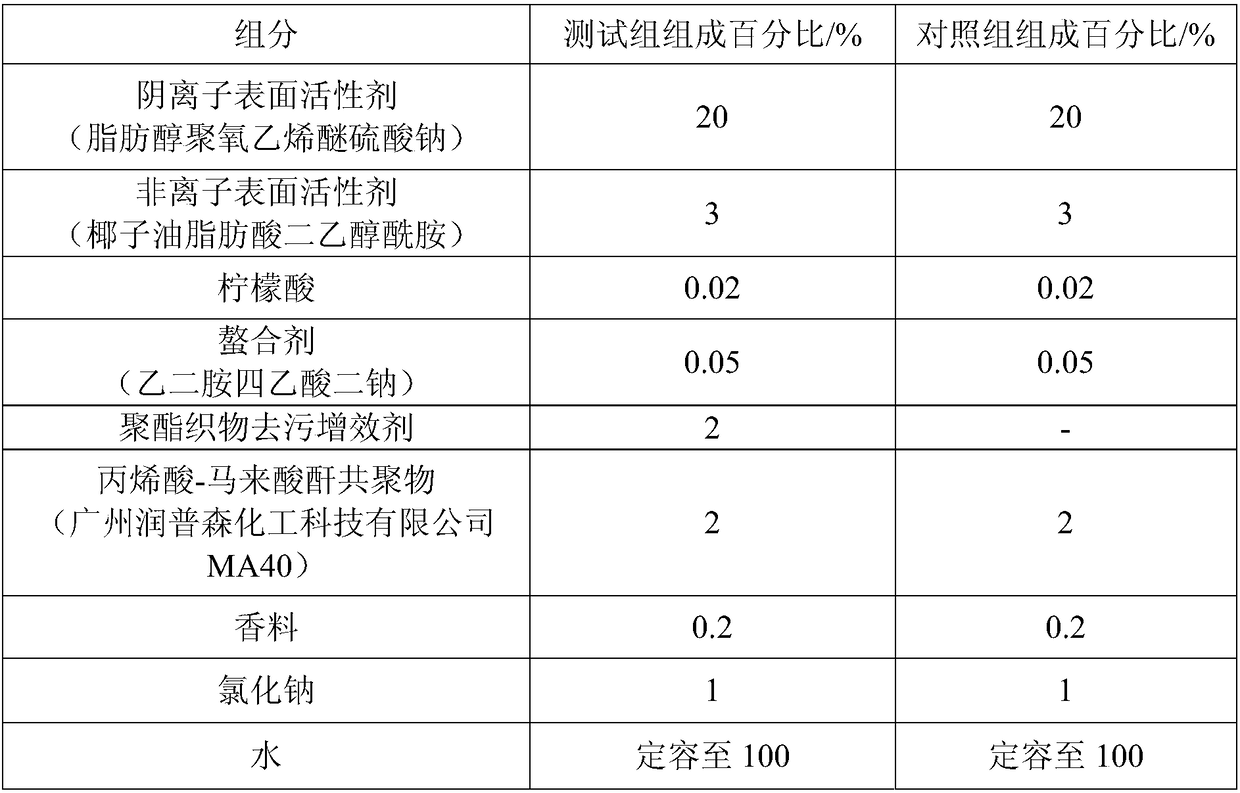

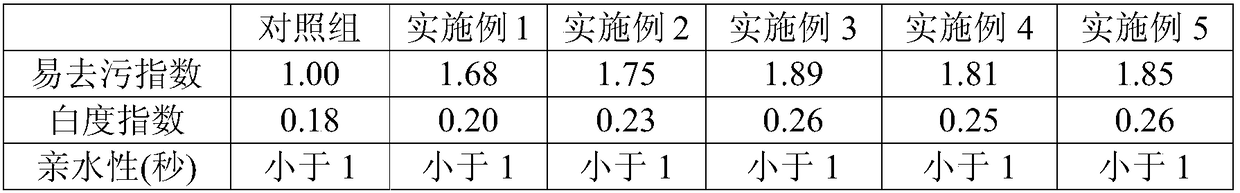

Examples

Embodiment 1

[0041] (1) Take by weighing 100 grams of dimethyl terephthalate, 70 grams of ethylene glycol, and 0.25 grams of manganese acetate; add the above-mentioned materials in the reaction kettle, heat up to 150° C., keep for 3.5 hours, and remove the low boilers by distillation. The transparent viscous liquid obtained is terephthalate;

[0042] (2) In the reaction system of step (1), add polyethylene glycol (molecular weight is 1000Da) 750 grams, triphenyl phosphate 5.00 grams, polycondensation catalyst (manganese acetate and antimony oxide mixture, mass ratio is 1:1) 1.25 gram, heated up to 230°C in a nitrogen atmosphere, kept at a constant temperature for 30 minutes, then carried out polycondensation reaction at a vacuum degree of -0.05MPa and a temperature of 240°C for 45 minutes, and cooled to 60°C to obtain a polyester polyether block copolymer;

[0043] (3) Add 23 grams of epichlorohydrin to the polyester polyether block copolymer that step (2) obtains, heat preservation reacti...

Embodiment 2

[0046] (1) Take by weighing 110 grams of dimethyl terephthalate, 80 grams of ethylene glycol, and 0.20 grams of magnesium acetate; add the above-mentioned materials in the reaction kettle, heat up to 160 ° C, keep for 3.0 hours, and distill off the low boilers, The transparent viscous liquid obtained is terephthalate;

[0047] (2) In the reaction system of step (1), add polyethylene glycol (molecular weight is 2000Da) 1000 grams, triphenyl phosphate 5.50 grams, polycondensation catalyst (zinc acetate and antimony oxide mixture, mass ratio is 1:1) 2.25 gram, heated up to 210°C in a nitrogen atmosphere, kept at a constant temperature for 40 minutes, then carried out polycondensation reaction at a vacuum degree of -0.05MPa and a temperature of 240°C for 60 minutes, and cooled to 65°C to obtain a polyester polyether block copolymer;

[0048](3) Add 45 grams of epichlorohydrin to the polyester polyether block copolymer that step (2) obtains, heat preservation reaction 1 hour, add 9...

Embodiment 3

[0051] (1) Take by weighing 100 grams of dimethyl terephthalate, 50 grams of ethylene glycol, and 0.25 grams of zinc acetate; add the above-mentioned materials in the reaction kettle, heat up to 180° C., keep for 3.5 hours, and distill to remove low boilers. The transparent viscous liquid obtained is terephthalate;

[0052] (2) In the reaction system of step (1), add polyethylene glycol (polyethylene glycol molecular weight is 2000Da) 640 grams, triphenyl phosphate 3.40 grams, polycondensation catalyst (zinc acetate and antimony oxide mixture, mass ratio 1: 2) 1.30 grams, heated up to 220°C in a nitrogen atmosphere, kept at a constant temperature for 60 minutes, then carried out polycondensation reaction at a vacuum degree of -0.08MPa and a temperature of 240°C for 60 minutes, and cooled to 70°C to obtain a polyester polyether block copolymer thing;

[0053] (3) Add 52 grams of epichlorohydrin to the polyester polyether block copolymer that step (2) obtains, heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com