Measuring device and measuring method for large three-dimensional morphology based on inertial navigation technology

An inertial navigation and measurement device technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of large size, poor flexibility, and low efficiency of feature measurement in local space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the drawings.

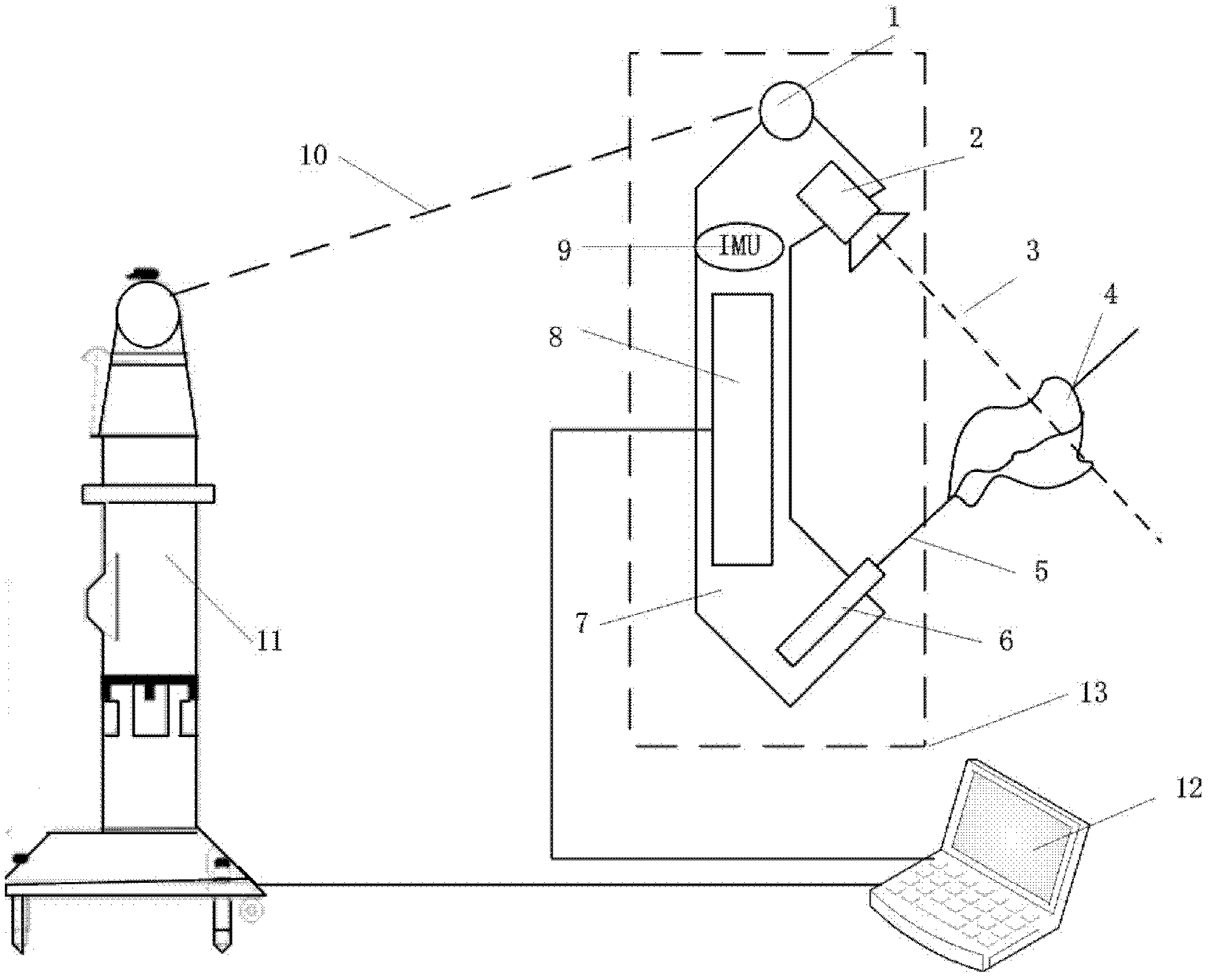

[0024] With reference to the drawings, a large-scale three-dimensional shape measurement device based on inertial navigation technology includes a laser tracker 11 and a portable handheld measurement terminal 13. The portable handheld measurement terminal 13 specifically includes a laser tracker target ball 1, a high-precision CCD camera 2, a semiconductor The laser projector 6, the handheld stand 7, the image processing and communication unit 8, and the inertial navigation unit 9. The high-precision CCD camera 2 is fixed on the upper part of the handheld stand 7, and the image processing and communication unit 8 is located in the middle of the handheld stand 7, which can The imaging information of the high-precision CCD camera 2 is processed in real time. The semiconductor laser projector 6 is clamped at the lower part of the hand-held bracket 7 to project a plane beam 5 to the meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com