Non-contact wave velocity extracting method of like surface acoustic wave of plating layer structure

A wave velocity extraction, non-contact technology, applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, process detection response signals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

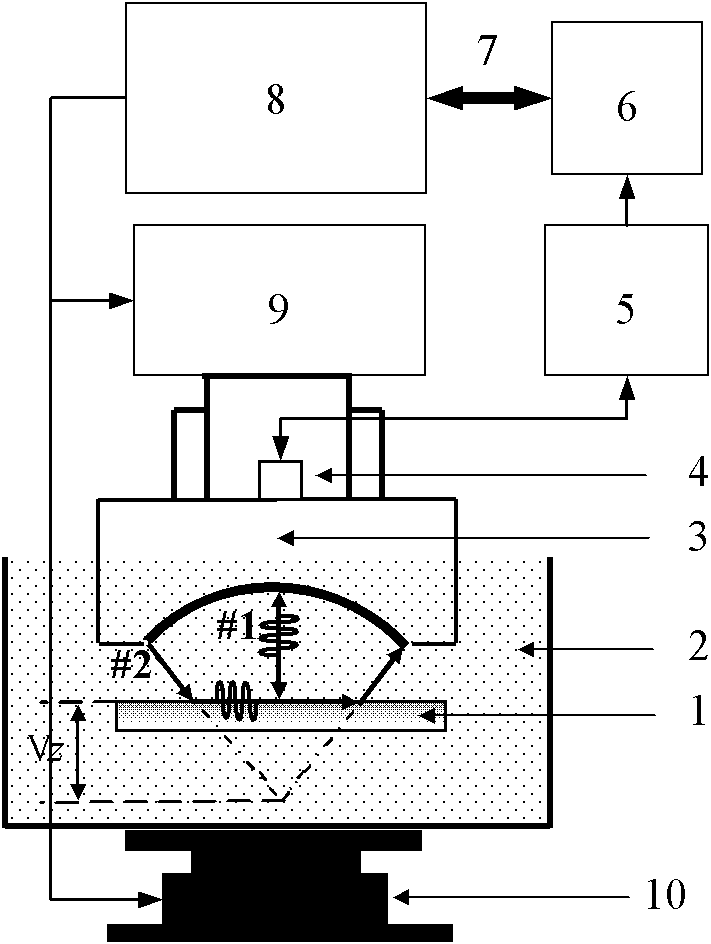

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with specific example, content of the present invention is described in further detail:

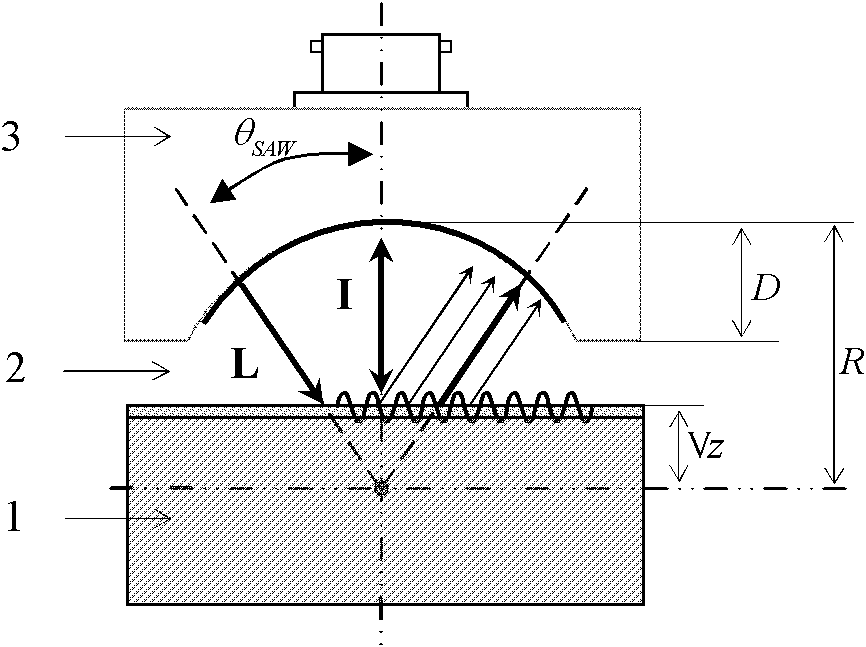

[0041] Step 1): Establish the formula for wave velocity extraction.

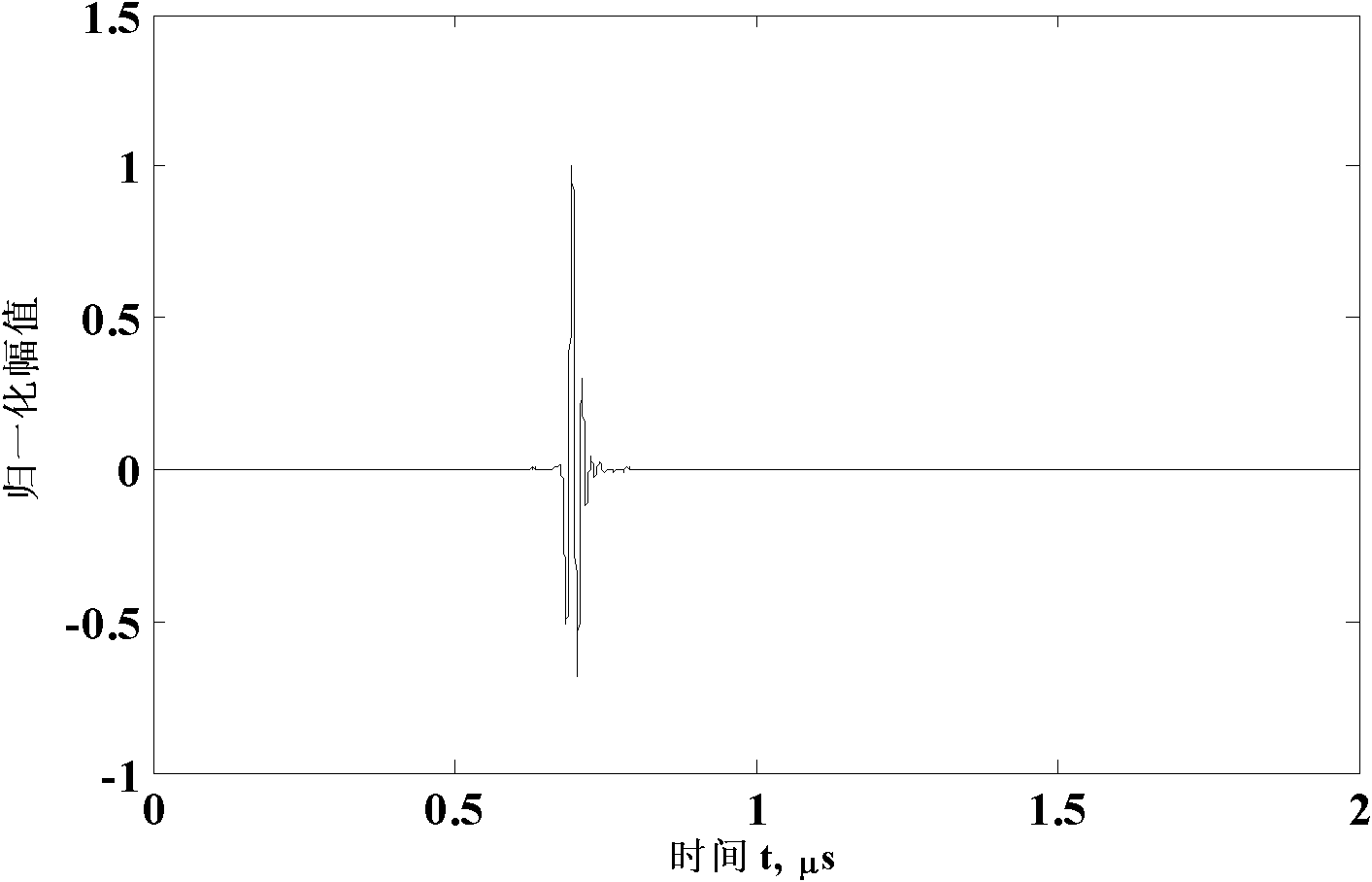

[0042] In the case of single frequency excitation / reception, figure 2 In the schematic diagram of the propagation of the leaky surface wave shown, the propagation time of the direct reflection echo I on the upper surface and the propagation time of the leaky surface wave L are respectively:

[0043] t 1 = 2 ( R - Vz ) v w - - - ( 1 )

[0044] t 2 = 2 ( R ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap