Rubber coating mechanism of high-speed automatic coil winding machine

An automatic winding machine, high-speed technology, applied in the direction of coil manufacturing, etc., can solve the problems of high cost, unfavorable mass production, and complex structure of the rubber-covered structure, and achieve simple structure, good economic effect and effect, and reduce the cost of the mechanism Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

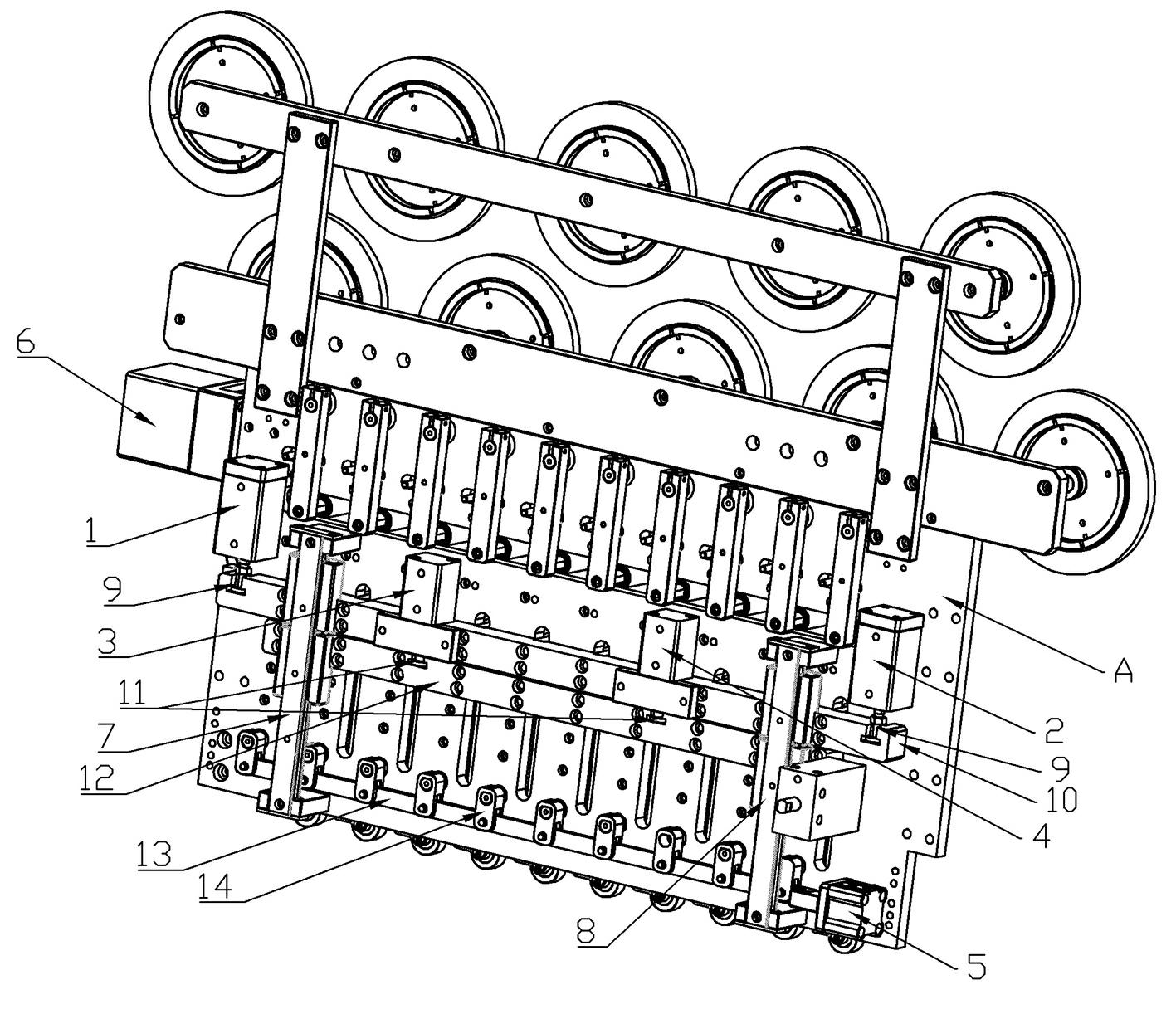

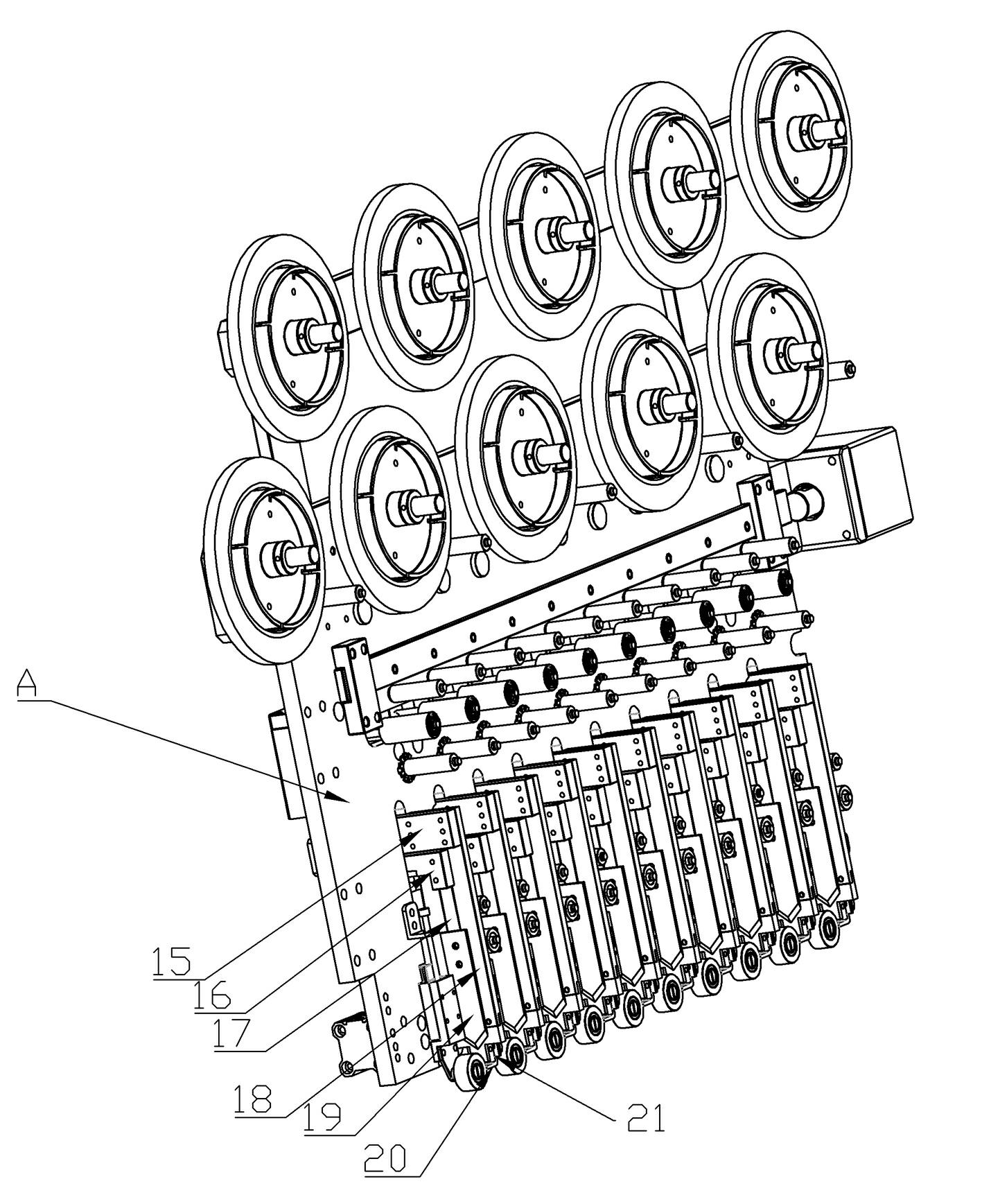

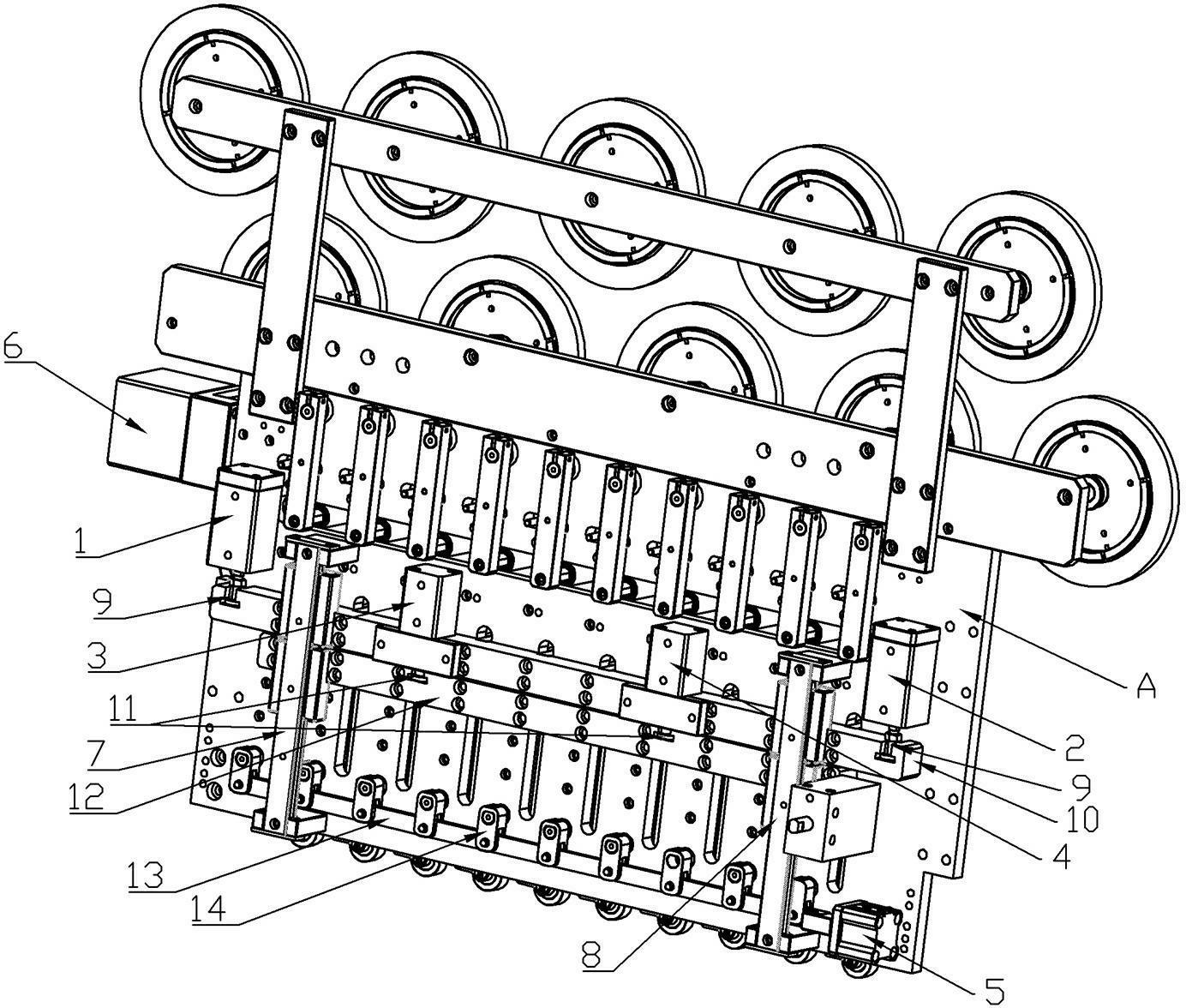

[0024] see Figure 1 to Figure 2 , the present invention is a high-speed automatic winding machine wrapping mechanism, which mainly includes:

[0025] The vertical plate connected with the main engine through the connecting piece, the first cylinder 1 and the second cylinder 2 fixed on the vertical plate A, the first cylinder joint 9 connected with the first cylinder 1 and the second cylinder 2 respectively, and The first cross arm 10 connected to the first cylinder joint 9 is a linear slide rail that is fixedly arranged on the vertical plate A and is slidably matched with the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com