Installation process of curved glass curtain wall

A technology of curved glass and installation technology, which is applied in the processing of walls, building materials, and building components, etc. It can solve problems such as changes in the chemical properties of structural silicone glue, poor stability of hidden frame curtain walls, etc., and achieve the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

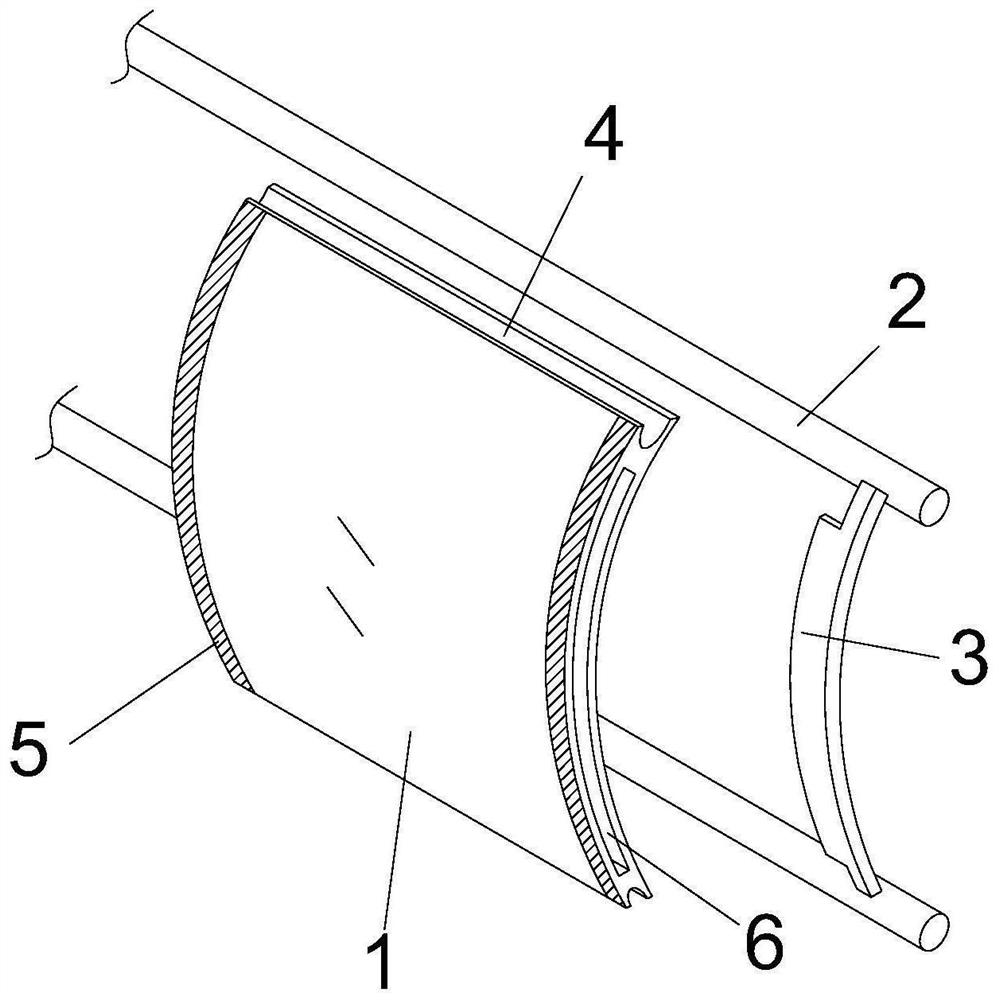

[0033] Embodiment: a kind of installation process of curved glass curtain wall, such asfigure 1 Shown, including the following working steps:

[0034] The first step: data collection and measurement data; for the design data collection of on-site civil engineering and the measurement of civil structure size, because the building may have some changes during construction, the actual size may not be completely consistent with the design drawing, the curved surface The glass curtain wall has high requirements on the size of the building structure, so it is necessary to go to the site to measure and obtain the actual data before designing, and then draw a feasible glass curtain wall division diagram according to the requirements. It is necessary to cooperate with the units that make automatic revolving doors and full glass doors, so that the glass curtain wall has a reliable closing position on the door and the door, determine the closing position of the curved glass curtain wall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com