High-power lithium-cathode-intercalated hybrid asymmetric super-capacitor pole piece and manufacturing method thereof

A technology for supercapacitors and manufacturing methods, applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, hybrid capacitors, etc., can solve problems such as increased safety concerns, battery heating, etc. area, the effect of increasing the instant contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

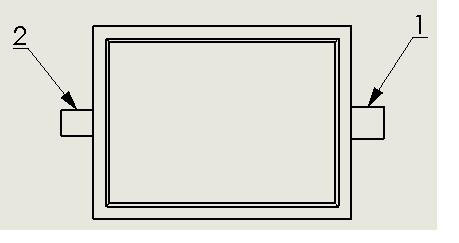

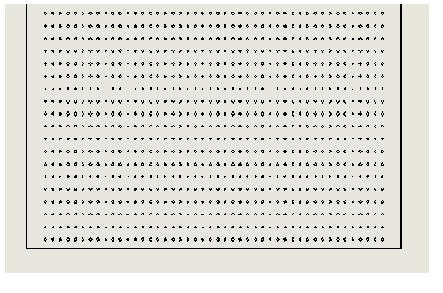

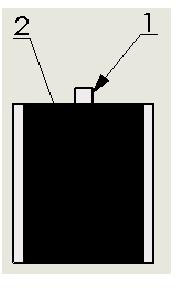

Image

Examples

Embodiment example 1

[0020] A metal aluminum mesh with a width of 300mm and a thickness of 0.1mm is used as the current collector of the electrode active material, wherein the width of the mesh area is 260mm, and a 20mm non-porous area is reserved on each side. Then the metal aluminum mesh is treated as follows, adding a strong basic anionic surfactant, using ultrasonic technology to decontaminate the surface of the current collector for 1.5min, washing it with secondary deionized water and then vacuuming it at 80°C After drying for 10 minutes, the current collector was surface-modified with a fluorine-containing surfactant for 4 minutes.

[0021] The conductive adhesive is applied once, and the treated metal mesh is coated with conductive adhesive. The thickness of the wet film on one side of the conductive adhesive is 15 μm.

[0022]For the second coating of activated carbon, when preparing the electrode active material slurry, first add 8g of carbon nanotubes to 150ml of absolute ethanol, ...

Embodiment example 2

[0028] Replace the carbon nanotubes in Example 1 with carbon nanofibers. The conditions for slurry mixing, pole piece fabrication, and battery assembly and testing are the same as those in Example 1. 10A charge and discharge, the voltage operating window is 2.0V-3.8V, the internal resistance of the supercapacitor is 0.55mΩ, and the electrostatic capacity is 2100F.

Embodiment example 3

[0030] The carbon nanotubes in Embodiment 1 are replaced by a mixture of carbon nanofibers and carbon nanotubes, and the sum of the masses of the two remains unchanged. The conditions for slurry mixing, pole piece fabrication, and battery assembly and testing are the same as those in Example 1. 10A charge and discharge, the internal resistance of the supercapacitor is 0.49mΩ, the voltage operation window is 2.0V-3.8V, and the electrostatic capacity is 2100F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com