A positive electrode of a hybrid capacitor and its preparation method and application

A hybrid capacitor and positive electrode technology, which is applied in the positive electrode of hybrid capacitors and its preparation field, can solve the problems of low energy density of carbon-based capacitors and the need for pre-embedded lithium treatment, etc., to improve charge and discharge performance, energy density and rate performance, The effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

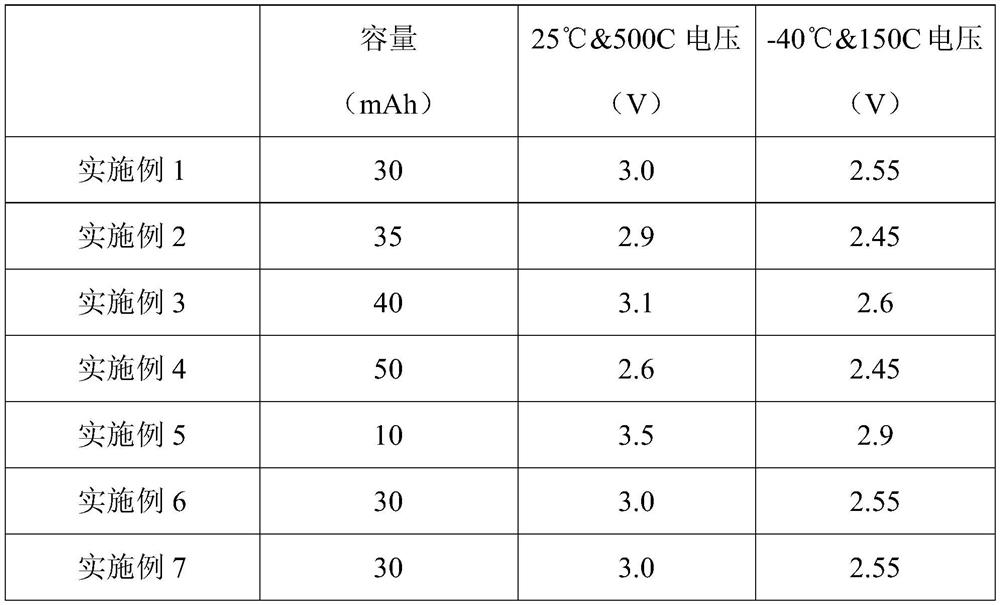

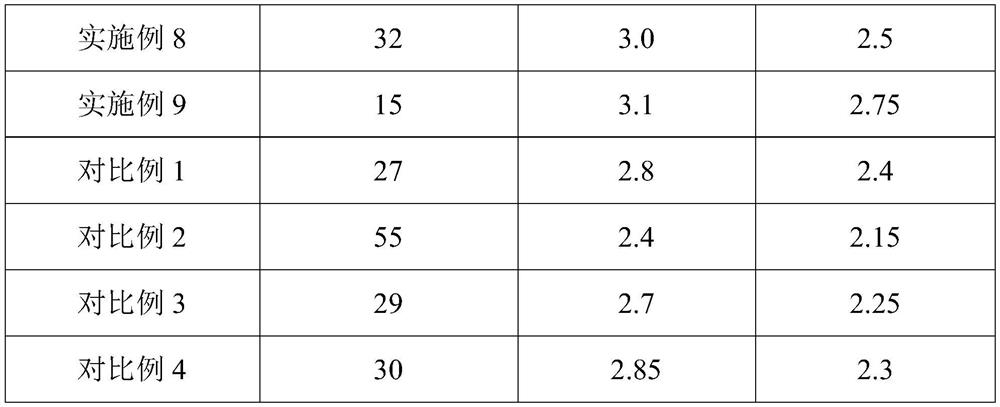

Examples

Embodiment 1

[0074] This embodiment provides a positive electrode of a hybrid capacitor, the positive electrode includes a current collector, and a bonding layer and a positive electrode material layer sequentially located on the surface of the current collector; the composition of the bonding layer is a first binder (specifically composed of PTFE with a thickness of 1 μm), the positive electrode material layer includes a second binder (specifically composed of PVDF), a conductive agent, a positive electrode active material and a lithium-rich compound, and the conductive agent includes a first conductive agent and a second conductive agent. agent, the first conductive agent is graphite powder, the second conductive agent is a mixture of graphene and carbon nanotubes with a mass ratio of 1:4; the positive electrode active material is a mixture of activated carbon and lithium cobaltate; the lithium-rich compound is Li 2 NiO 2 ;

[0075] Wherein, the total mass fraction of the first binder l...

Embodiment 2

[0082] This embodiment provides a positive electrode of a hybrid capacitor, the positive electrode includes a current collector, and a bonding layer and a positive electrode material layer sequentially located on the surface of the current collector; the composition of the bonding layer is a first binder (specifically composed of PVDF with a thickness of 0.5 μm), the positive electrode material layer includes a second binder (specifically composed of PTFE), a conductive agent, a positive electrode active material and a lithium-rich compound, and the conductive agent includes a first conductive agent and a second conductive agent. Conductive agent, the first conductive agent is acetylene black, the second conductive agent is a mixture of graphene oxide and carbon nanotubes in a mass ratio of 2:3; the positive electrode active material is a mixture of graphene and lithium manganate; the lithium-rich compound is Li 3 N;

[0083] Wherein, the total mass fraction of the first bind...

Embodiment 3

[0090] This embodiment provides a positive electrode of a hybrid capacitor, the positive electrode includes a current collector, and a bonding layer and a positive electrode material layer sequentially located on the surface of the current collector; the composition of the bonding layer is a first binder (specifically composed of PFA, with a thickness of 5 μm), the positive electrode material layer includes a second binder (specifically composed of PFA), a conductive agent, a positive electrode active material and a lithium-rich compound, and the conductive agent includes a first conductive agent and a second conductive material. agent, the first conductive agent is SP, the second conductive agent is a mixture of graphene and carbon nanotubes with a mass ratio of 2:4; the positive active material is a mixture of activated carbon and NCM811; the lithium-rich compound is Li 2 O;

[0091] Wherein, the total mass fraction of the first adhesive layer and the second adhesive layer i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com