Light-emitting assembly

A technology of light-emitting elements and light-emitting stacks, which is applied to electrical components, semiconductor devices, circuits, etc., and can solve the problems of reduced luminous efficiency of the light-emitting component 100 and decrease in brightness of the light-emitting component 100

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are described below with reference to the accompanying drawings.

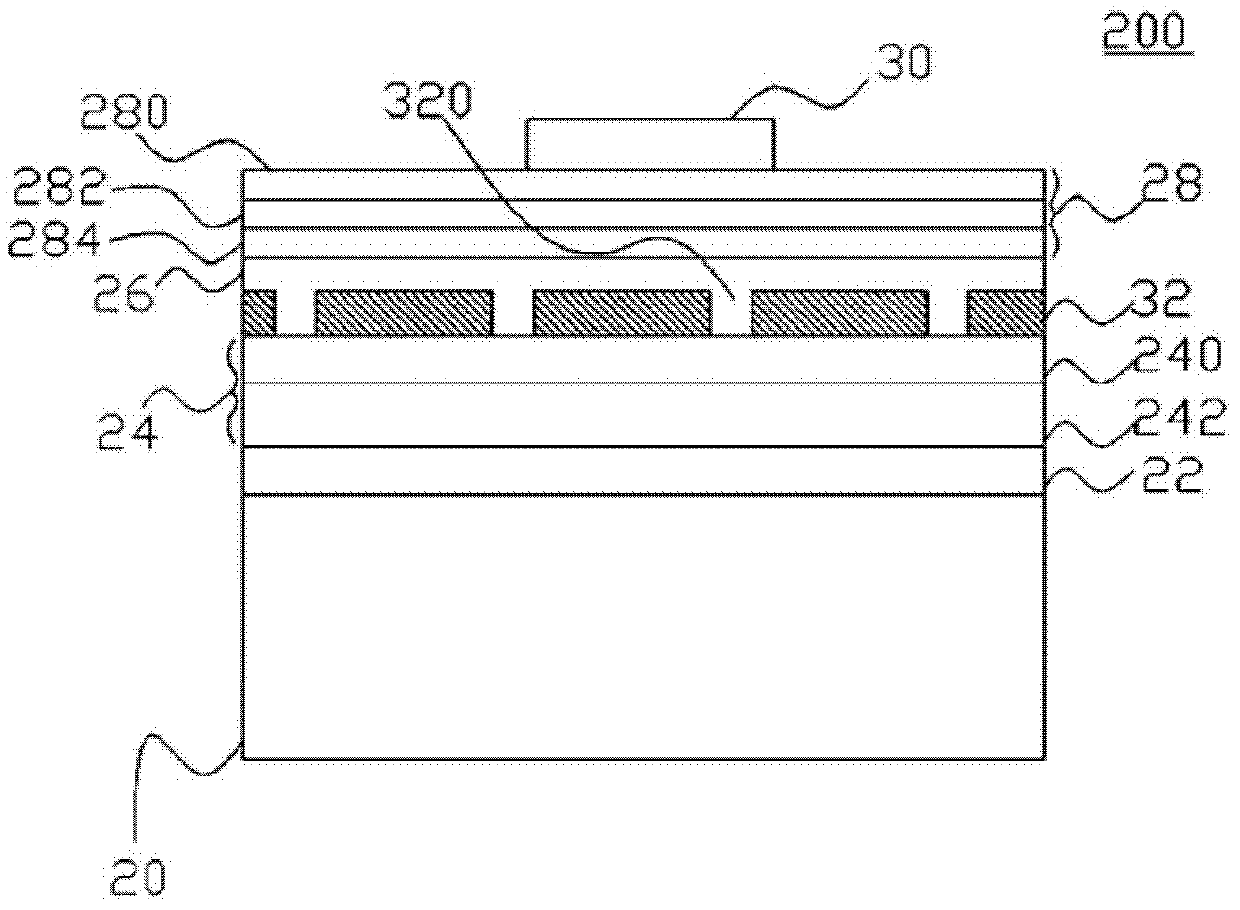

[0040] figure 2 It is a structural schematic diagram of an embodiment of the present invention, such as figure 2 As shown, the light-emitting component 200 includes a conductive substrate 20, an adhesive layer 22 disposed on the conductive substrate 20, an omni-directional reflective layer 24 (omni-directional reflector, ODR) located on the adhesive layer 22, and an omni-directional reflector located on the aforementioned omni-directional reflective layer 24. The first transparent conductive oxide layer 26, the light emitting stack 28 disposed on the first transparent conductive oxide layer 26; and the electrode 30 located on the light emitting stack 28; wherein, the omnidirectional reflective layer 24 and the first transparent conductive The oxide layer 26 further includes a transparent insulating barrier layer 32 , and the omnidirectional reflective layer 24 furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com