One-wall energy-saving sunlight greenhouse

A solar greenhouse, one-sided technology, applied in greenhouse cultivation, horticulture, climate change adaptation, etc., can solve the problems of unreasonable lighting angle design, difficulty in planting tall plants, insufficient light intensity, etc., to improve land utilization and photosynthesis. Effective, high-efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

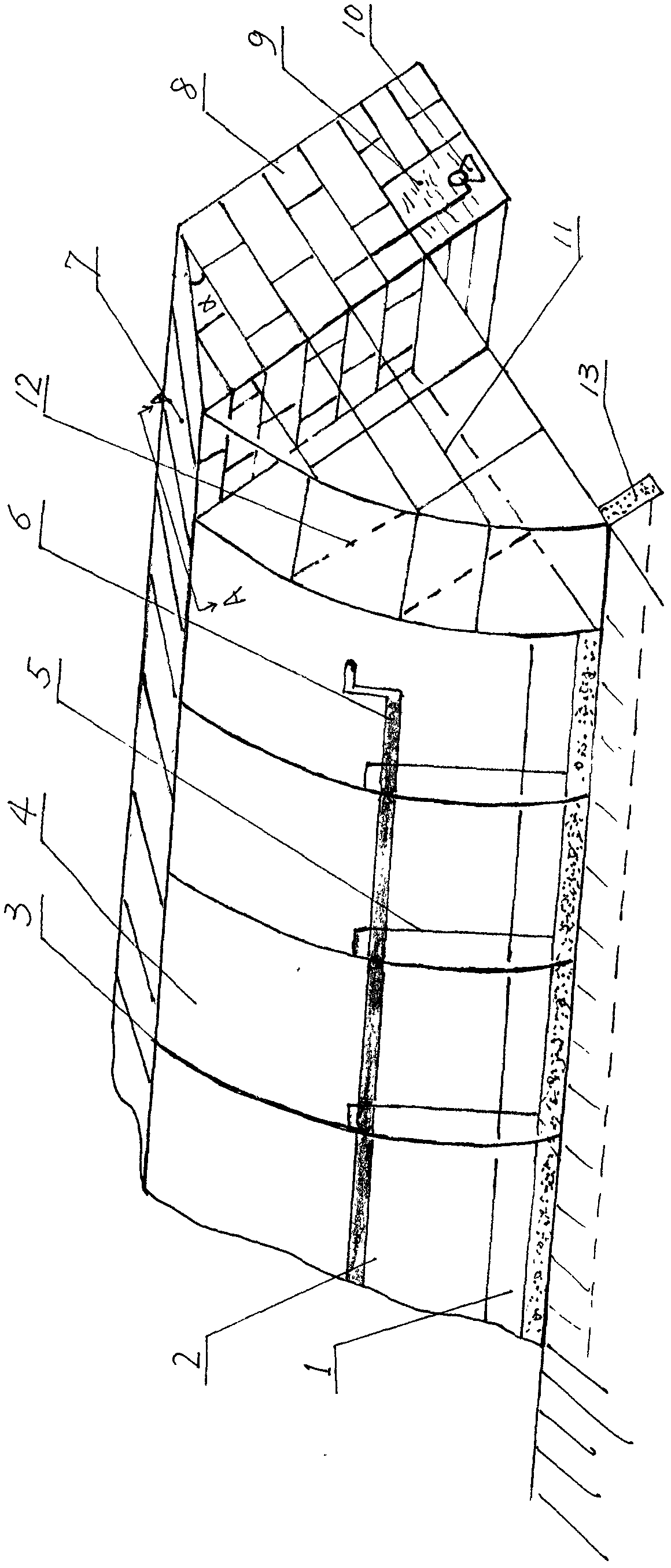

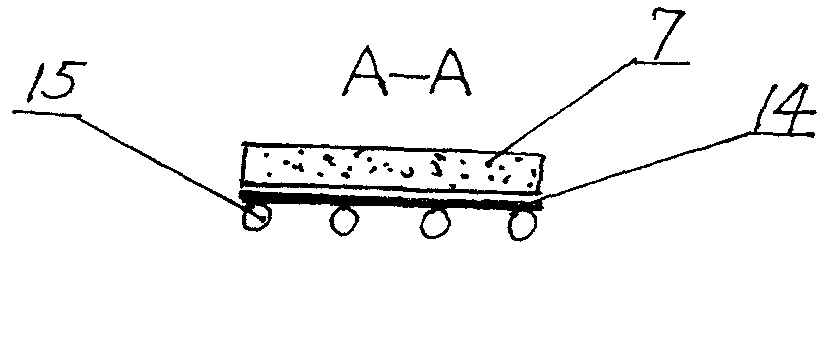

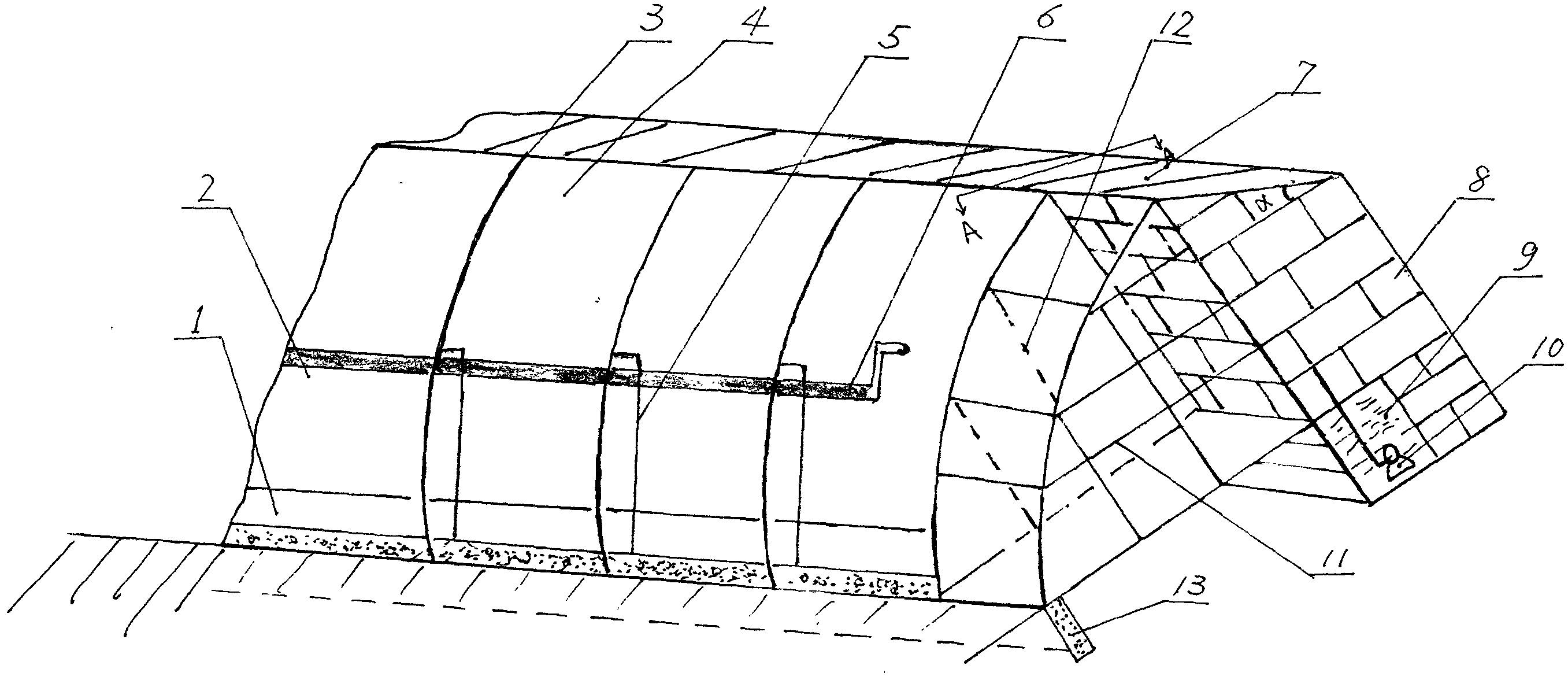

[0013] see figure 1 , the present invention is composed of a gable, back wall, back slope and an arc-shaped lighting shed surface composed of a skeleton and a light-transmitting film to form an integral greenhouse. The back wall 8 is an earth wall or a brick wall, and the skeleton 3 is arranged on the arc-shaped lighting shed In the inside of the surface, the skeleton 3 is covered with a plastic light-transmitting film 4, and the skeleton shed surface is covered with thermal insulation materials (such as insulation quilts, insulation boards, straw curtains, etc.); The frame 3 extends to the length of the original gable, and the frame 3 is connected with the frame 3 by columns at intervals of 0.5 to 1 meter, and 2-3 tie bars are arranged horizontally to connect with the columns; The light-transmitting layer formed by the grid of the light film; the light-transmitting layer is provided with two layers of the outer light-transmitting layer and the inner light-transmitting layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com