Seedling raising bed and seedling raising method for electric lighting greenhouse of sweet potatoes

A seedling bed and electric heating technology, applied in the field of seedling raising, can solve the problems of inability to effectively improve the yield and quality of seedlings, high dependence on natural weather and environment, and high requirements for operators' abilities, and achieves the advantages of neat seedling emergence, easy management and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

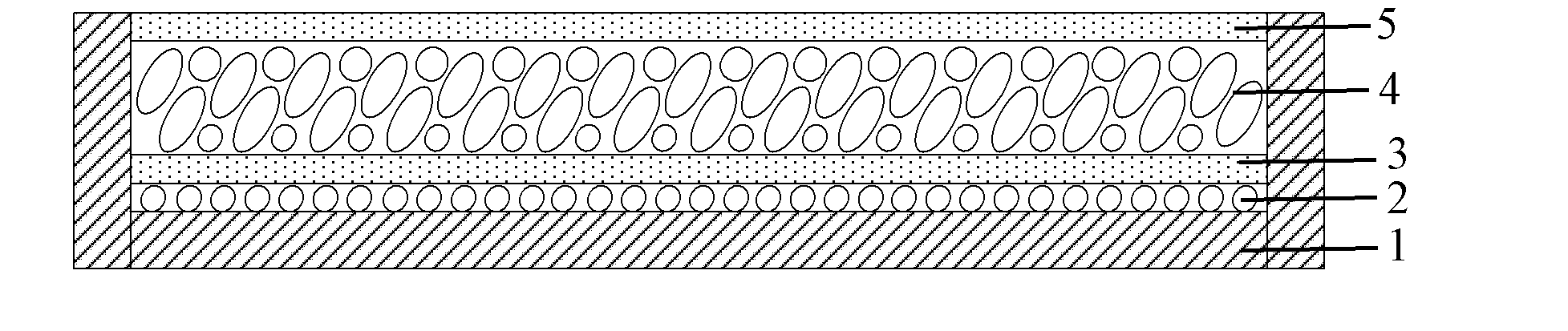

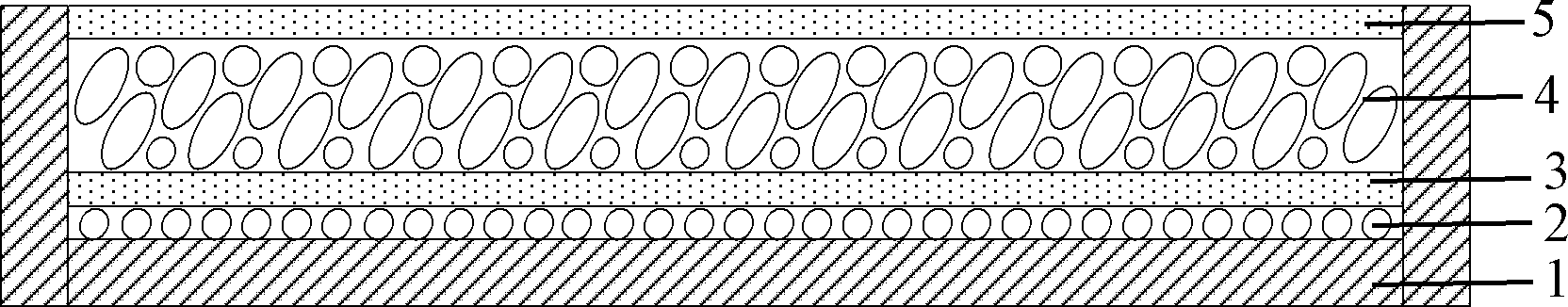

[0025] figure 1 Shows the schematic cross-sectional view of the sweet potato electric heating greenhouse seedling bed of the present embodiment, with reference to the illustration, it includes the grooved furrow 1 repaired in the greenhouse, and the electric heater laid in the grooved furrow 1 successively from bottom to top Layer 2, sand isolation layer 3, seed potato layer 4 and sand covering layer 5, the electric heating layer 2 is connected to an external power supply, and the external power supply supplies power to the electric heating layer 2 to increase the temperature of the seedbed.

[0026] Wherein, the electric heating layer 2 is laid on the bottom surface of the groove furrow 1 by an electric heating wire in a Z shape, and the two ends of the electric heating wire are exposed outside the groove furrow 1, and the two ends are respectively connected to the outer A power supply and a thermostat, the thermostat is used to control the heating temperature of the electric...

Embodiment 2

[0030] This embodiment provides a seedling raising method based on the greenhouse seedling bed of Embodiment 1, and its specific seedling raising process is as follows.

[0031] First of all, the treatment of seed potatoes after they come out of the cellar: according to the planning requirements of the sweet potato planting period, push forward about 40 days, the seed potatoes are selected in sunny, warm and windless weather, and they are released from the cellar at one time. Slightly dry in a warm and sunny place to remove moisture, and grade and select according to the bed requirements. The high-quality seed potatoes should be straight and smooth in appearance, and the weight of a single piece is 150-250g. Put the selected potato cubes into 0.2% carbendazim or thiophanate-methyl solution for 20-25 minutes for disinfection, remove internal infected nematodes, and remove the potato cubes floating in the water. The soaked potato pieces are taken out, dried, and then transported...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com