Digging machine for tree planting

A technology of a digging machine and a frame is applied in the field of tree planting digging machines, which can solve the problems of inapplicability and increase the cost, and achieve the effects of convenient movement, reduced labor intensity and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

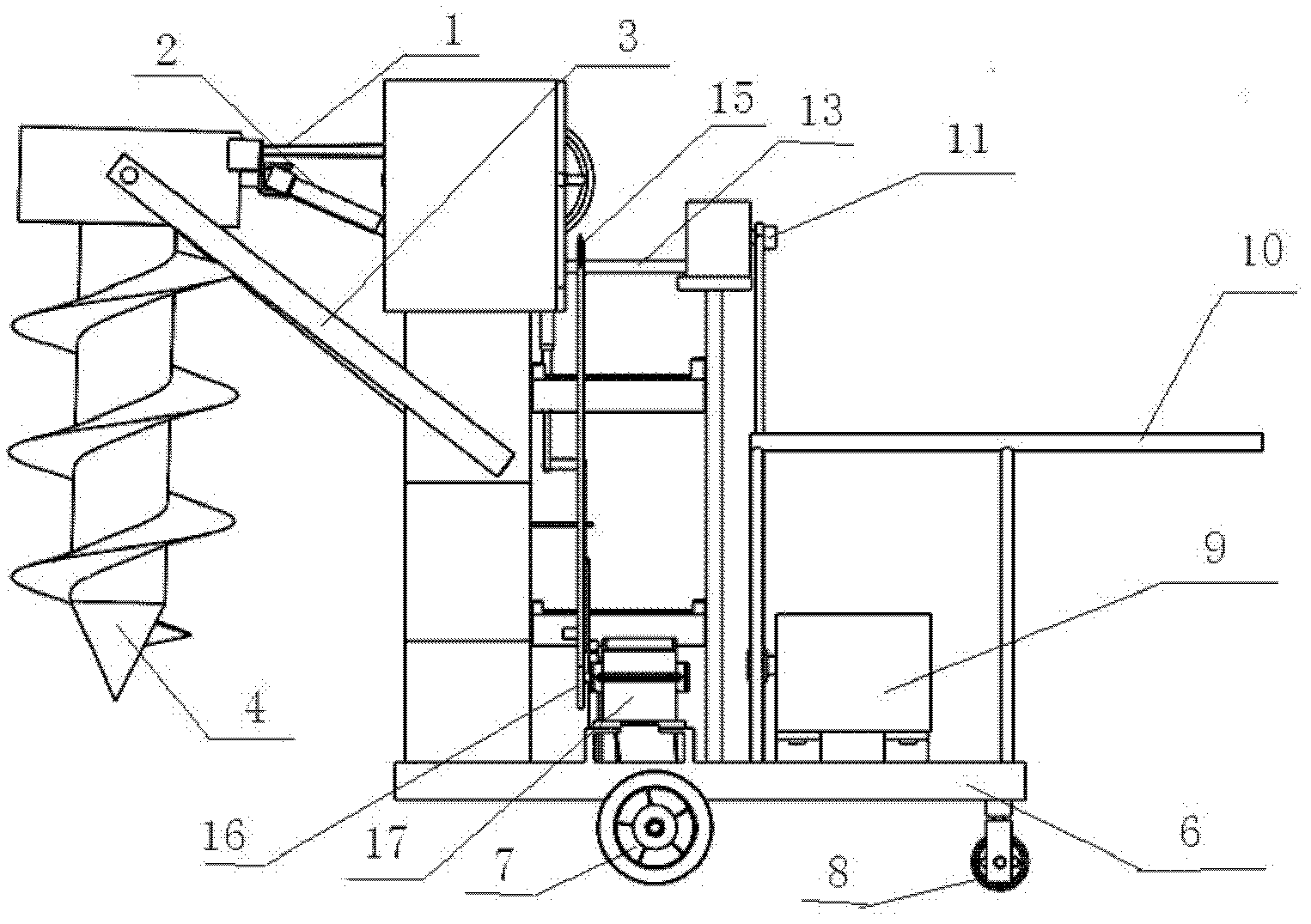

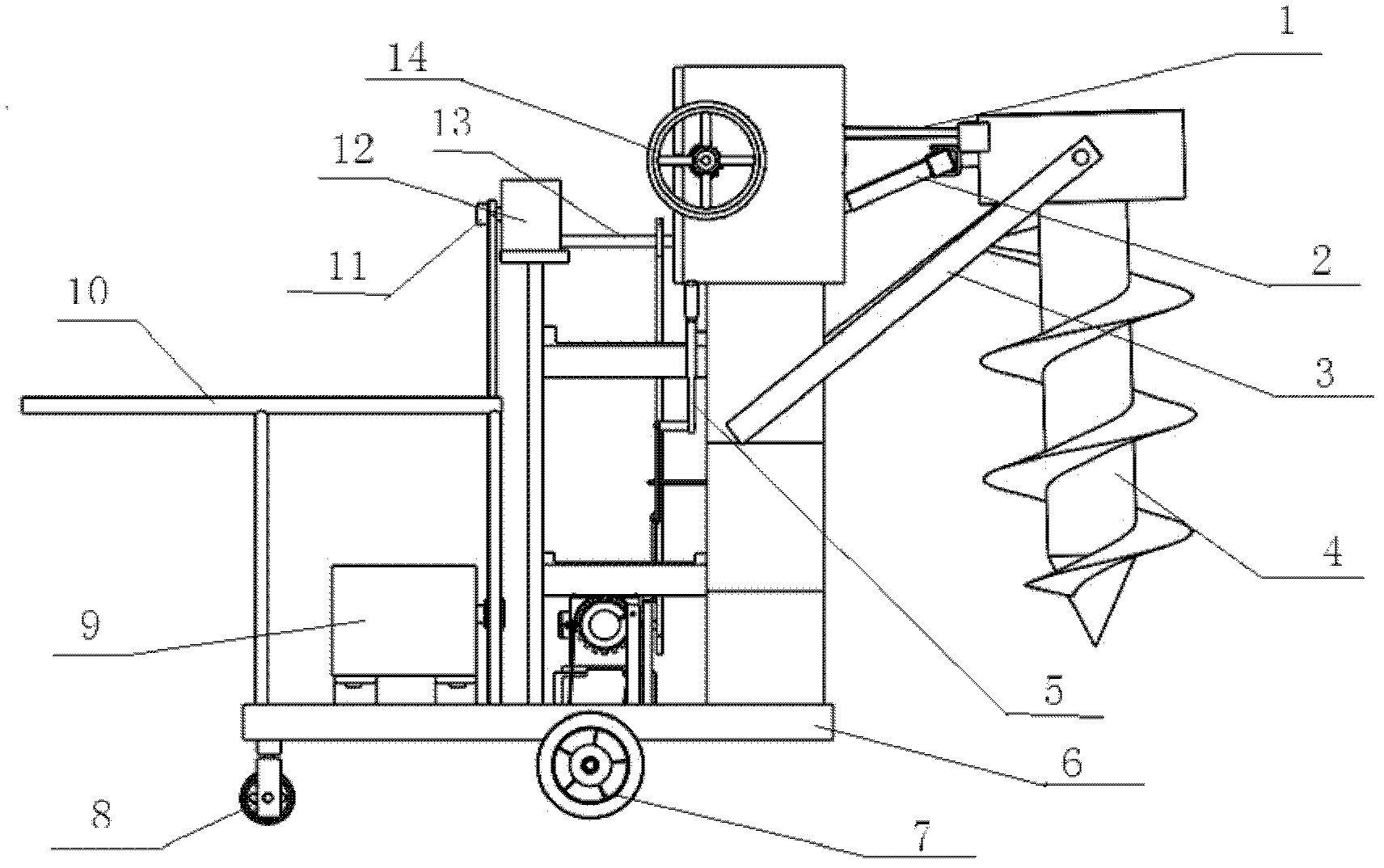

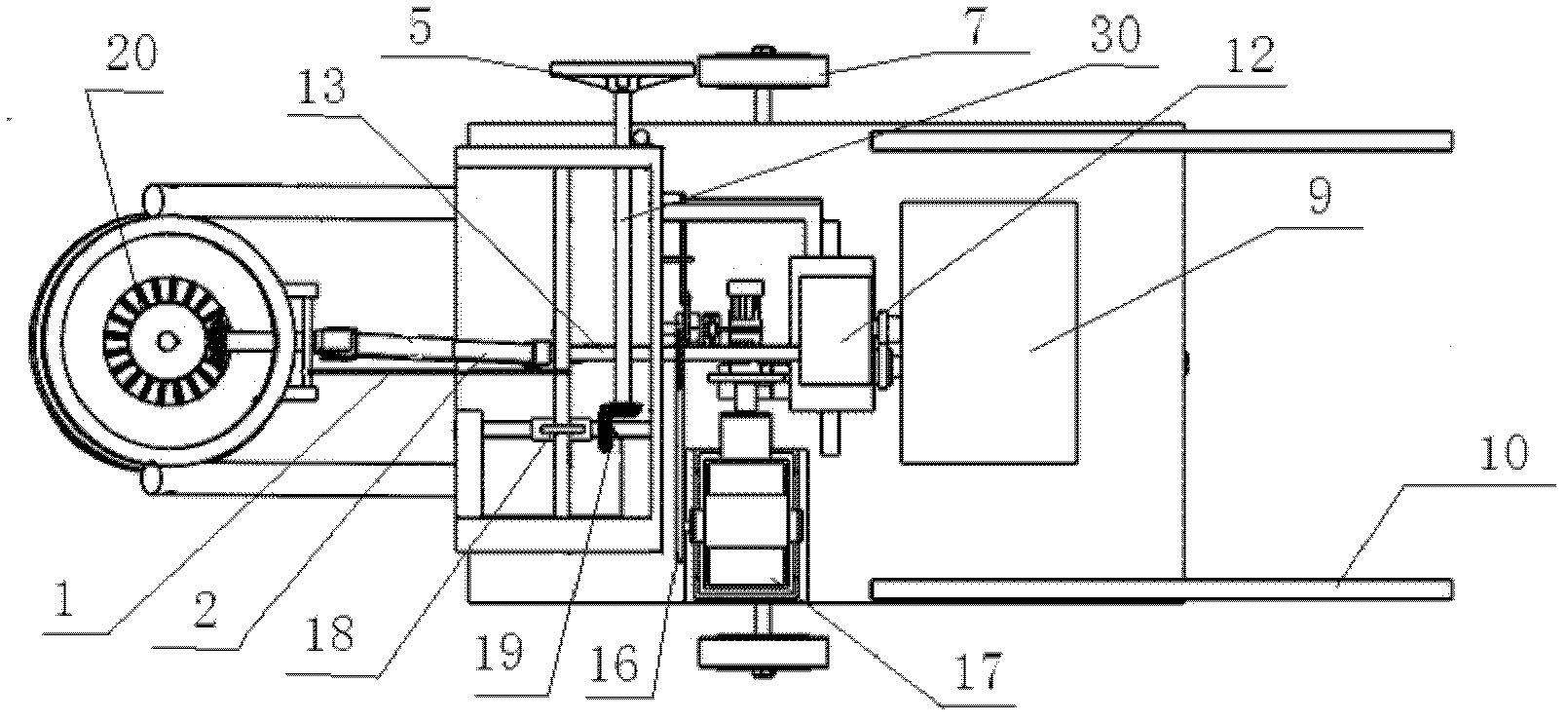

[0015] Such as Figure 1 to Figure 6 Shown, tree planting pit digging machine of the present invention mainly is made up of power mechanism, transmission mechanism, running gear, digging pit mechanism and frame 6.

[0016] The power mechanism is an independent diesel engine, which is not restricted by the place of use, which reduces the cost of the whole machine.

[0017] The transmission mechanism includes a pulley 11, a clutch 12, a transmission shaft 13, a first sprocket 15, a second sprocket 16, a reducer 17, a coupling 29, a spline shaft 27, a spline connection sleeve 23, a diesel engine 9 and a clutch 12 Connected by pulley 11, clutch 12, transmission shaft 13, first sprocket 15, second sprocket 16, speed reducer 17, shaft coupling 29, spline shaft 27, spline connection sleeve 23 are connected in sequence. The power is transmitted to the spline shaft 27 by the diesel engine 9 through the pulley 11, the clutch 12, the transmission shaft 13, the first sprocket 15, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com