Hot riveting rod for hot riveting machine

A technology of hot riveting machine and riveting rod, which is applied in the field of hot riveting welding, can solve the problems of insufficient riveting strength, unstable welding quality, unstable temperature, etc., and achieve the effect of enhancing riveting strength, increasing heat insulation effect, and high welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described below in conjunction with accompanying drawing.

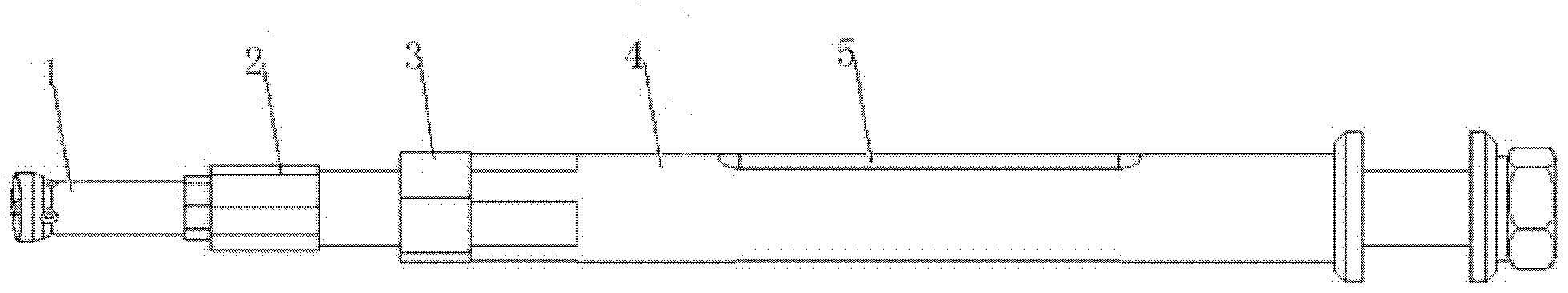

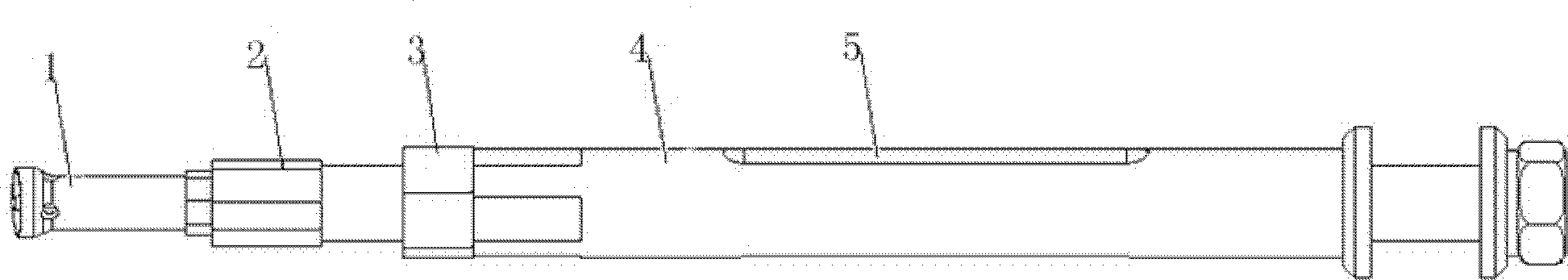

[0012] attached figure 1 It is a hot riveting rod for a hot riveting machine according to the present invention, comprising a riveting rod body 2; one end of the riveting rod body 2 is provided with a hot riveting head 1, and the other end is connected to the riveting rod support column 4 through a nut 3; The rod body 2 is made of stainless steel, and the rivet rod support column 4 is provided with a waist-shaped groove 5, which ensures that most of the temperature of the heating pipe is stored on the hot riveting head 1, and enhances the riveting strength of the riveting machine; at the same time, the hot riveting head 1 is Mushroom shape, the material is made of beryllium copper, which ensures that the riveting points are riveted into a mushroom shape, making the appearance smooth and the welding strength high.

[0013] The above-mentioned embodiments are only to illustrate the techn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com