Working-face automated integrated control system for thin seam drum shearers

A technology of integrated control system and centralized control system, which is applied in the direction of cutting machinery, earth drilling, cutting machinery, etc., can solve the problem of unmanned or few-person mining at the working face, misjudgment of the position and direction of the shearer, Misoperation etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

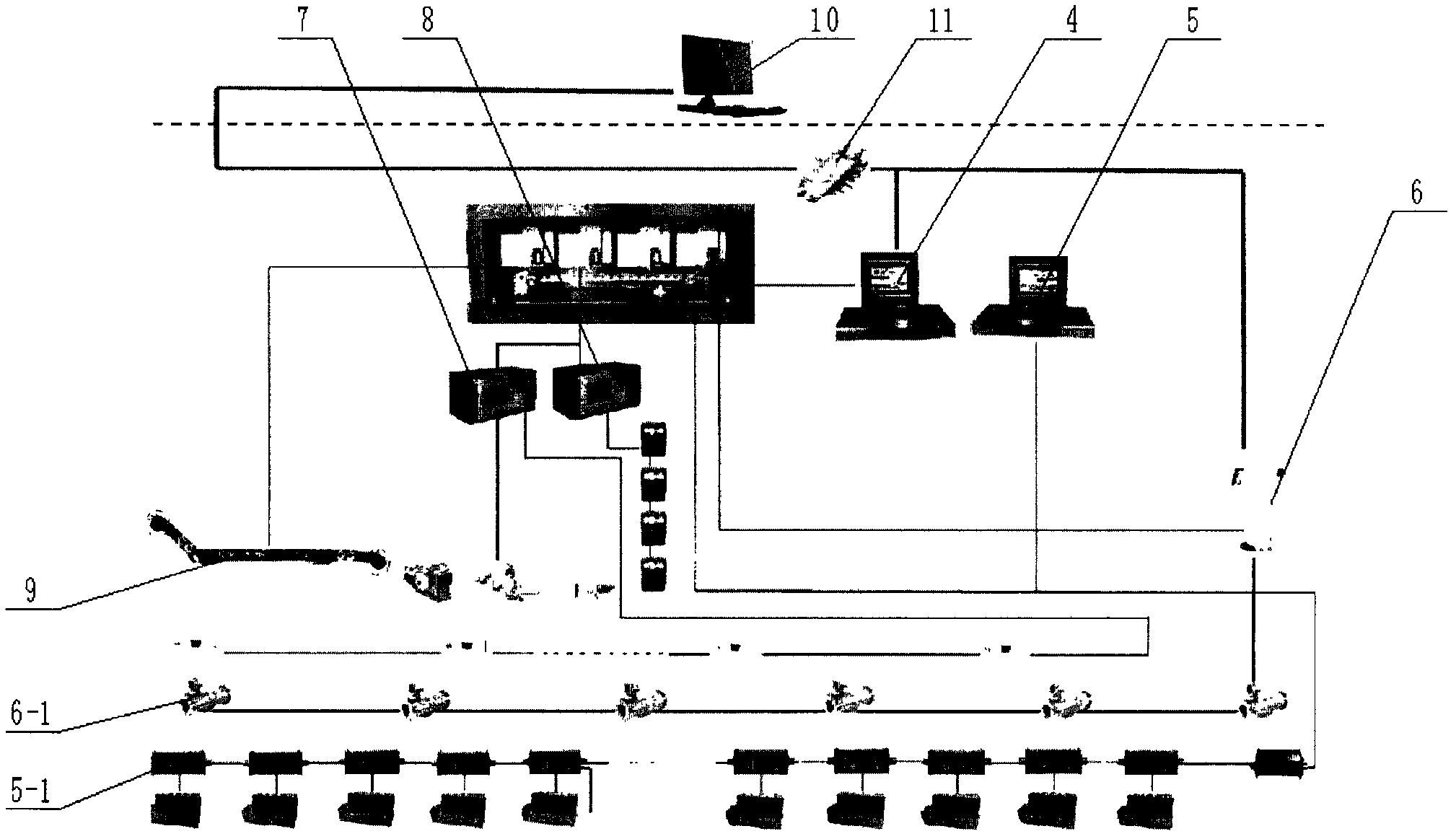

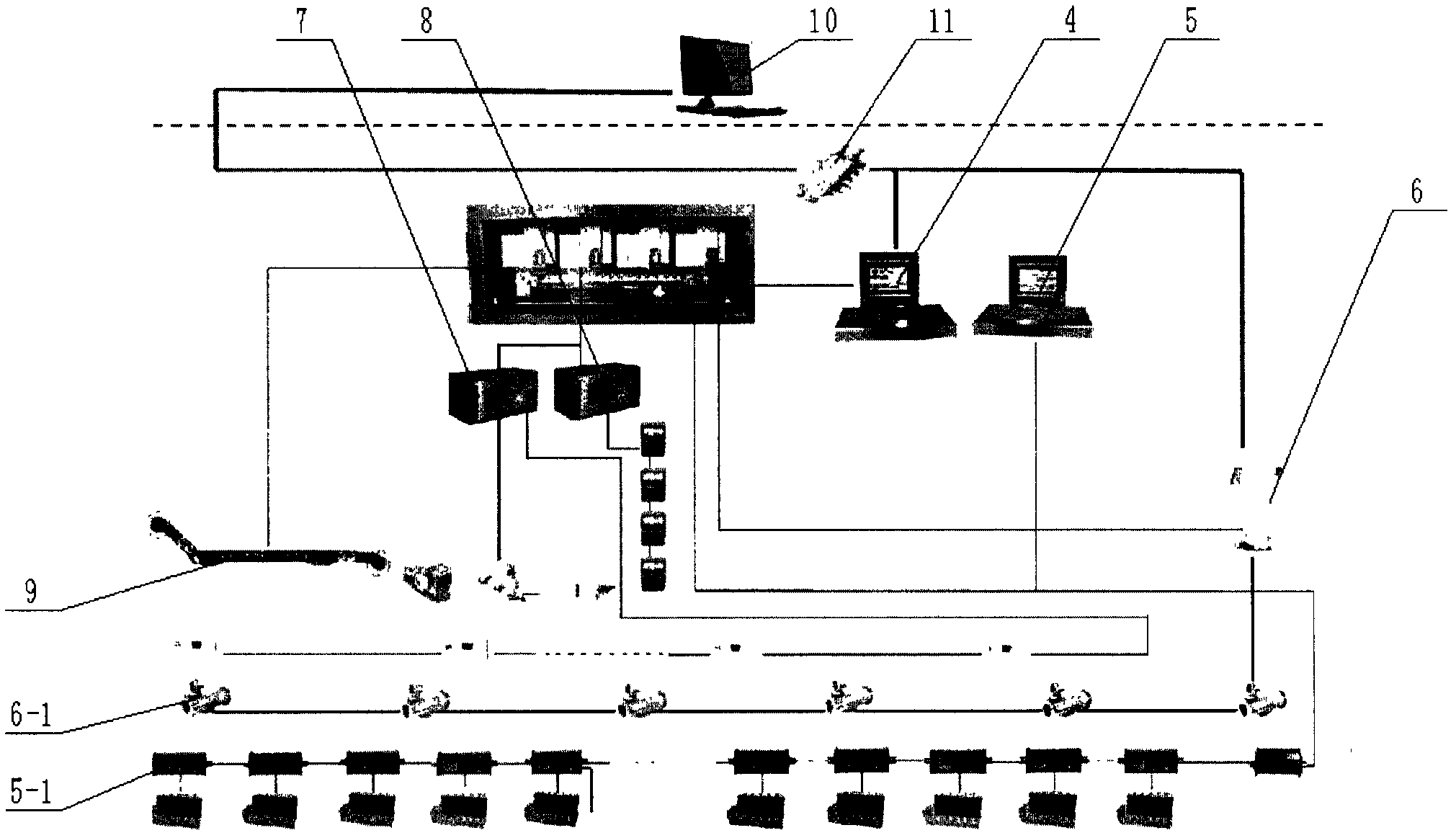

[0011] The automatic integrated control system of the working face of the thin coal seam drum shearer mainly includes the centralized control system 4 of the working face, the electro-hydraulic control system of the bracket 5, the video monitoring system of the working face 6, the voice communication and emergency stop control system of the working face 7, and the complete set of conveyor equipment Monitoring system 8, shearer memory cutting and remote control system 9, and ground control center 10, wherein an electro-hydraulic control system controller 5-1 and a video camera 6-1 are installed on the hydraulic support. The centralized control system 4 of the working face converts the data formats of different control systems into one format for unified control through the data coupler, and realizes the two-way real-time communication of data between the coal mining machine, the hydraulic support and the scraper conveyor on the working face, and The accurate position, direction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com