Hydraulic system for precisely arranging stator shielding sleeve of nuclear main pump in gapless attachment way

A hydraulic system and shielding sleeve technology, applied in the field of nuclear power, can solve problems such as poor attachment, loading pressure that cannot be changed according to requirements, and difficult control of molding pressure, etc., to achieve seamless plastic deformation attachment, wide pressure range, The effect of increasing the upper pressure limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

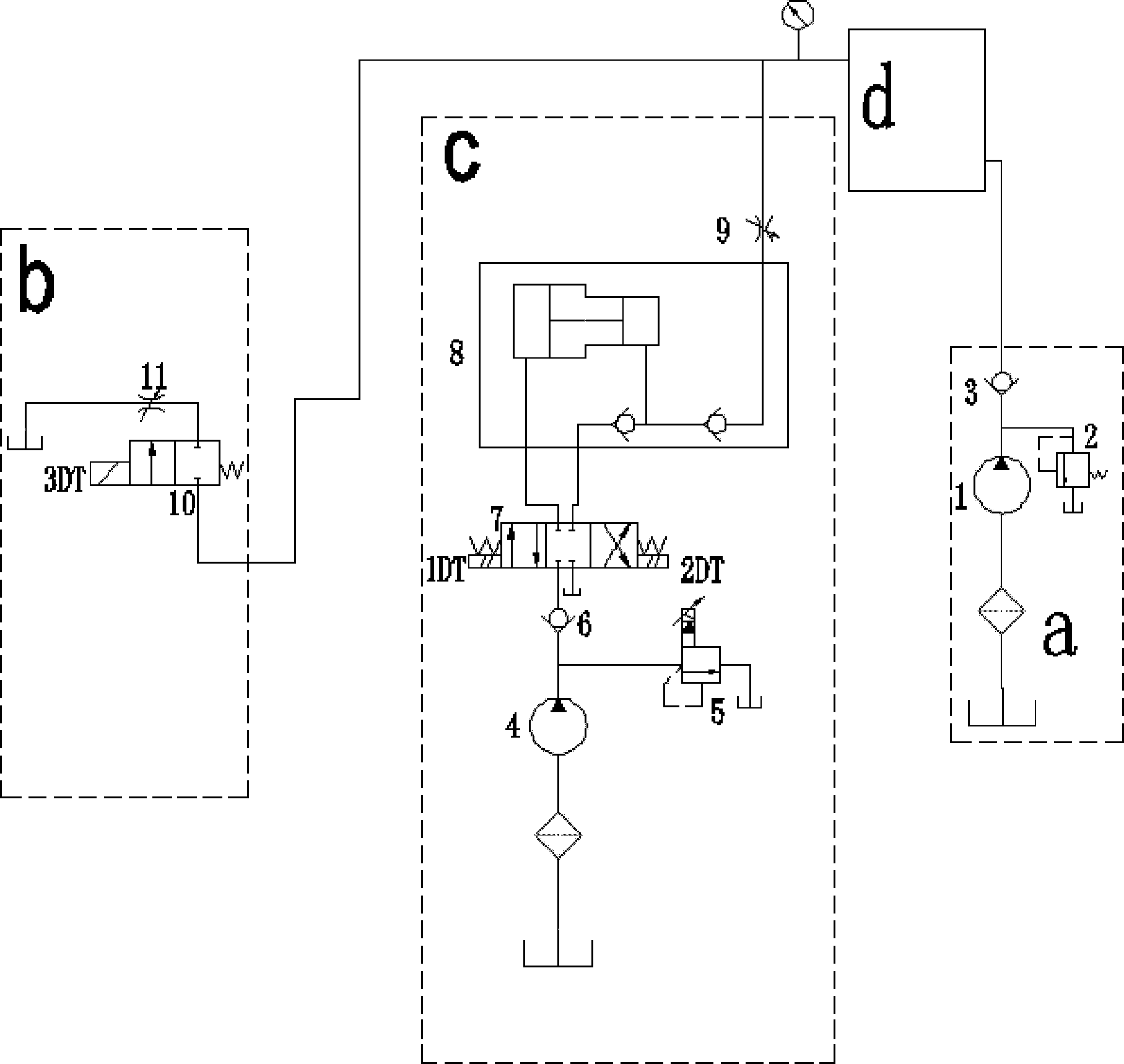

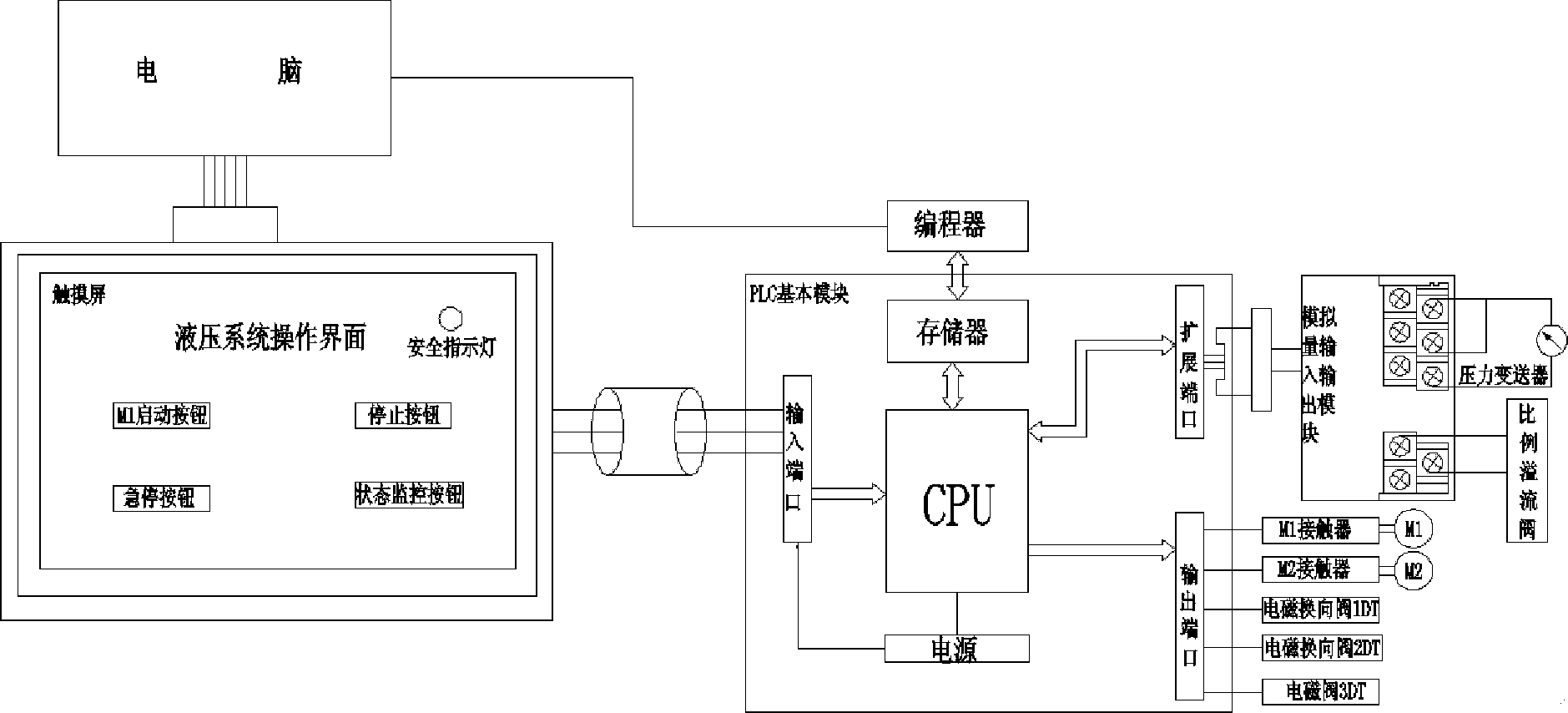

[0016] figure 1 It shows a hydraulic system diagram for the gapless attachment and precision installation of the stator shielding sleeve of the nuclear main pump. In the figure, the hydraulic system includes a liquid filling part a, an exhaust part b and a pressurizing part c. In the liquid-filled part a, the airtight cavity formed by the first gear pump 1 is filled with low-pressure oil, and a relief valve 2 for safety protection is set at the outlet of the pump, behind the relief valve 2 to prevent The first one-way valve 3 is set for the reverse flow of oil. In the exhaust part b, the electromagnetic valve 10 and the second throttle valve 11 are used to discharge the gas in the sealed cavity. In the pressurization part c, the low-pressure hydraulic oil source is provided by the second gear pump 4, and the input current of the proportional relief valve 5 is adjusted through the analog output signal of the PLC to control the outlet pressure of the second gear pump 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com