Cold mass radial supporting device for liquefied natural gas cylinder

A technology of liquefied natural gas and radial support, applied in the method of container discharge, gas/liquid distribution and storage, container filling method, etc., can solve the problems of reducing heat conduction, strengthening the stability of LNG cylinders, etc. Simple structure and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

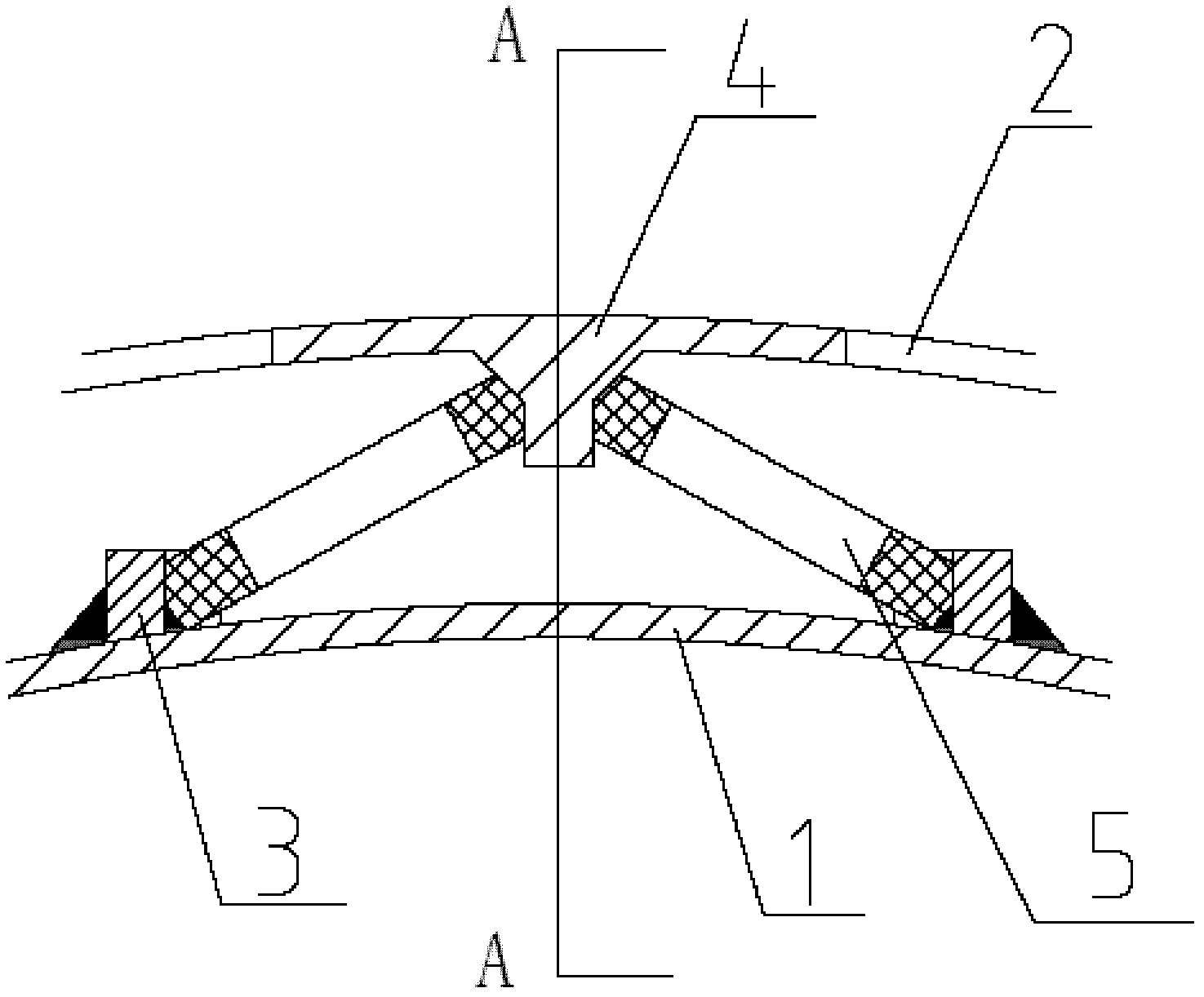

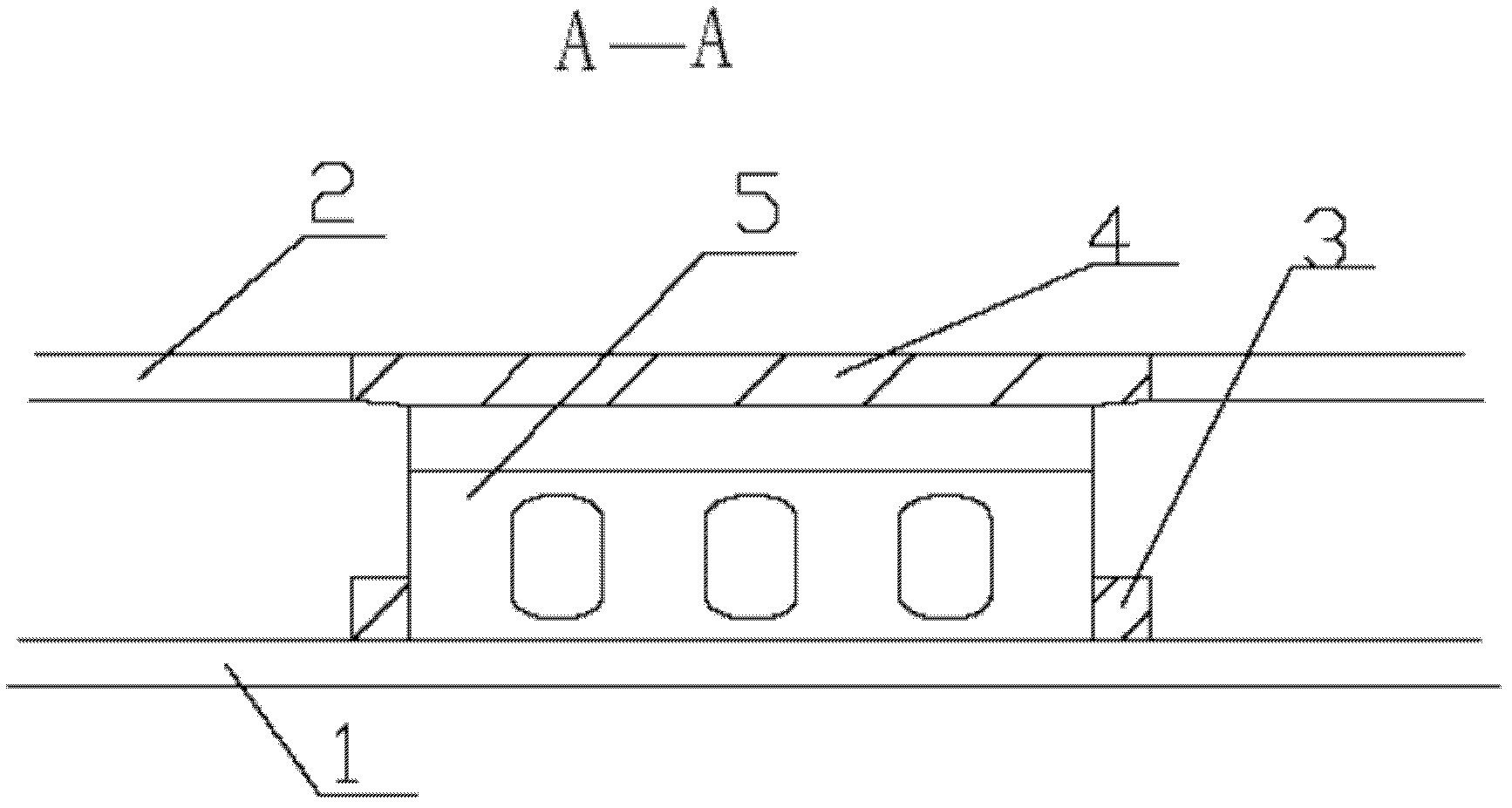

[0008] Specific implementation mode one: combine figure 1 and figure 2 Explain, a cold mass radial support device for liquefied natural gas cylinders in this embodiment, the cold mass radial support device includes a support assembly 4, two support members 3 and two support plates 5;

[0009] The length direction of the two support members 3 is parallel to the axial direction of the inner cylinder 1 of the liquefied natural gas cylinder, and the two support members 3 are affixed to the outer side wall of the inner cylinder 1 of the liquefied natural gas cylinder (preferably adopting a fixed connection method of spot welding, contacting small area), the support assembly 4 is affixed to the inner side wall of the liquefied natural gas cylinder outer cylinder 2 (preferably adopting spot welding for affixation, the contact area is small), and the support assembly 4 is located in the middle of the two support members 3, and the two The support plate 5 is arranged between the inne...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 2 It is explained that there are three holes on the support plate 5 in this embodiment. In order to reduce the heat conduction area and ensure the strength requirements. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 Note that the cross-sectional shape of the support assembly 4 in this embodiment is composed of an integrated isosceles trapezoid and a rectangle. On the surface, the arc surface of the support assembly 4 is affixed to the inner wall of the outer cylinder of the liquefied natural gas cylinder (preferably adopting the affixation method of spot welding, the contact area is small). Such design has the characteristics of high strength. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com