Detachable plate heat exchanger for heat exchange of cold and heat source fluid such as sewage and refrigerant

A plate heat exchanger and refrigerant technology, applied in indirect heat exchangers, heat exchange equipment, heat exchanger types, etc., can solve the problem of small single-plate heat transfer, poor pressure-bearing capacity of plates alone, unsuitable, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

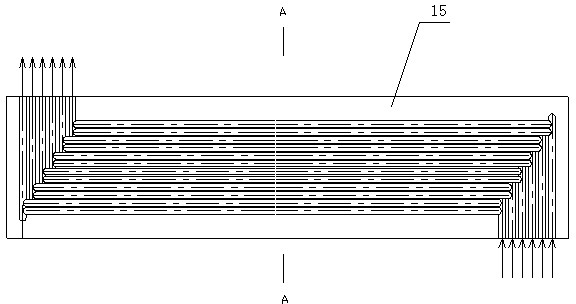

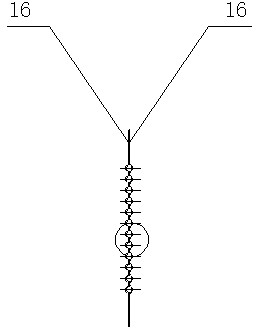

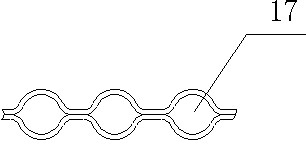

[0043] Example 1, see Figure 1 to Figure 3 , the figure shows a typical plate heat exchange unit 15 (plate pair) structure, the plates 16 made of carbon steel, alloy steel, non-ferrous metals and their alloys are processed to a certain degree of concave and convex by stamping and other methods shape, and then the two plates 16 are stacked together, and the contact parts are integrally sealed and connected into a plate heat exchange unit 15 by means of laser welding, argon shielded arc welding, plasma arc welding, resistance welding or brazing—— Plate pair. The plates form refrigerant flow channels 17 inside to ensure that the internal fluid flows at a certain speed and along a certain direction. The plate pair is provided with refrigerant inlet and outlet.

[0044] In order to improve its pressure bearing capacity and enhance heat transfer, the internal refrigerant flow channel 17 of the plate pair can be designed and processed into different shapes according to the charact...

Embodiment 2

[0045] Example 2, see Figure 4 to Figure 6 , The plate heat exchange unit 15 can also be in another form—a whole plate integrally formed. The plate is melted with metal material and hollowed out inside to form the refrigerant flow channel 17 through a special process, or the metal material is melted and integrally cast on the prefabricated mold to form a complete refrigerant flow channel 17 inside. As mentioned above, the shape of the cross-section of the internal refrigerant flow channel can also be circular, elliptical, etc., and the inner surface of the flow channel and the outer surface of the plate can also be made smooth or ribbed with threads, bumps, etc. , to enhance heat transfer.

[0046] Heat exchanger scheme:

[0047] In the heat exchanger of the present invention, the plate heat exchange unit is used as the basic unit, and a plurality of plate heat exchange units placed in parallel are arranged according to the heat exchange requirements. Connected in a combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com