Device for testing water vapor permeability by aid of weighing method

A water vapor transmission rate and testing device technology, which is applied in measuring devices, material weighing, permeability/surface area analysis, etc., can solve the problems of low data accuracy, low degree of detection automation, and low test efficiency, and achieve universality Strong, simple structure, easy application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

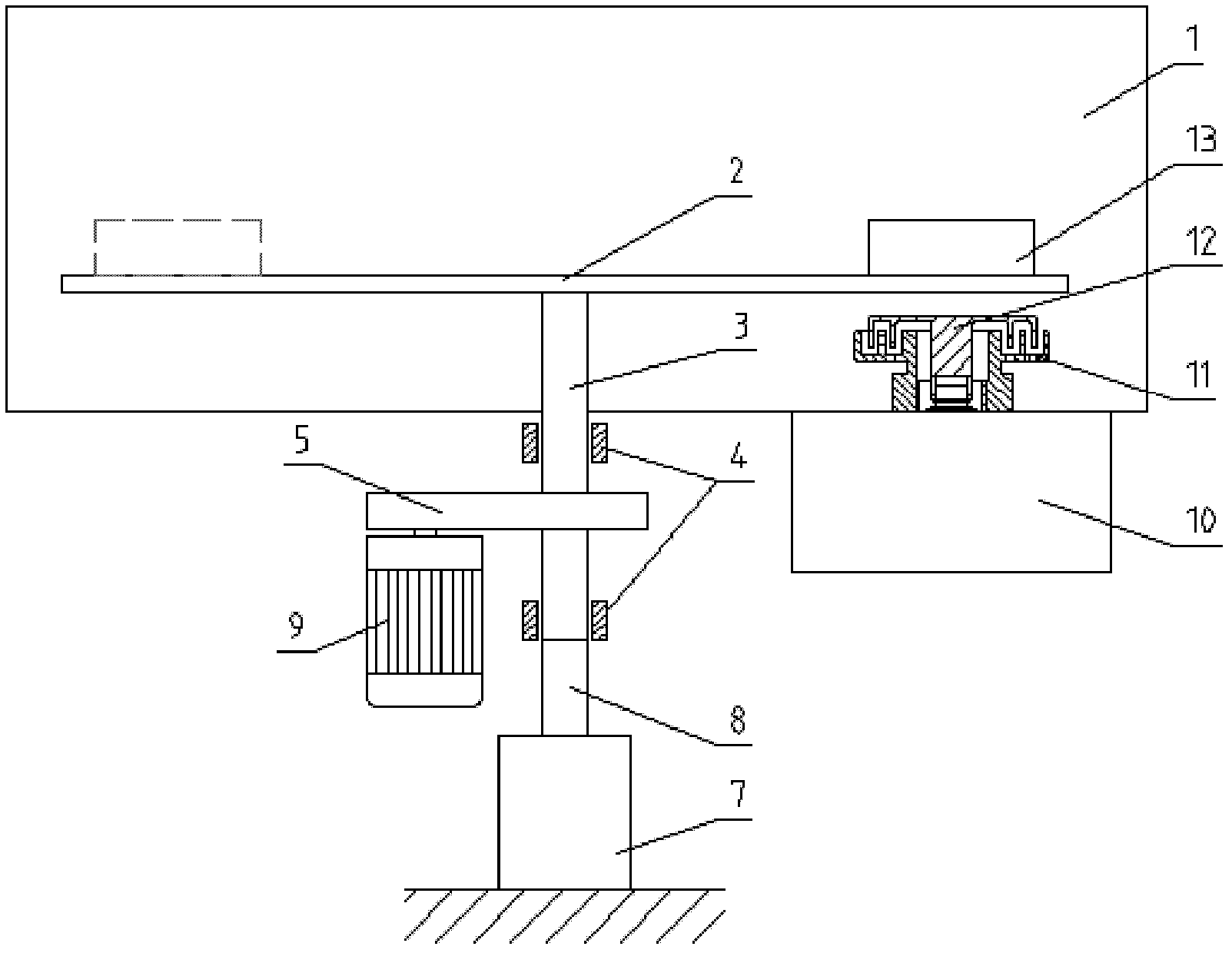

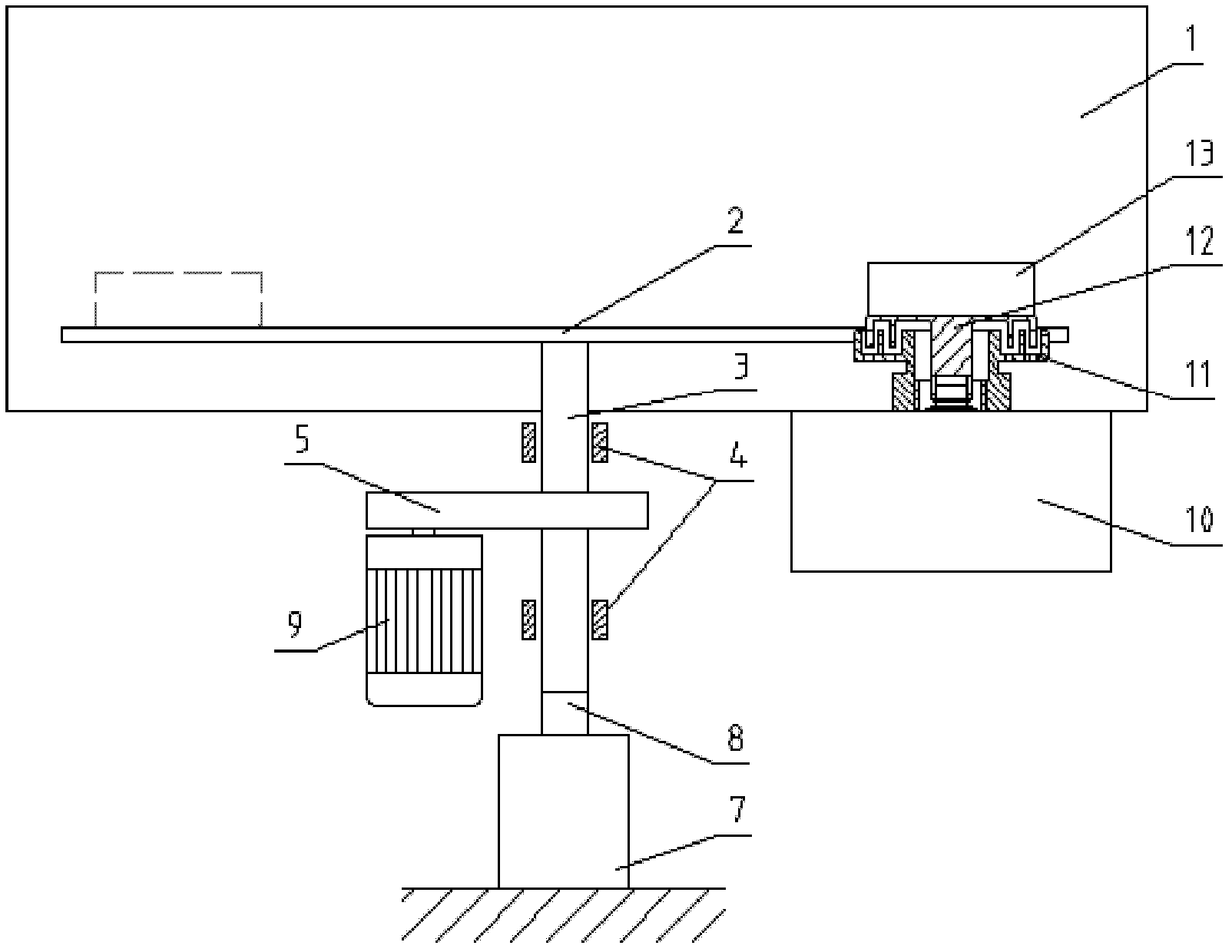

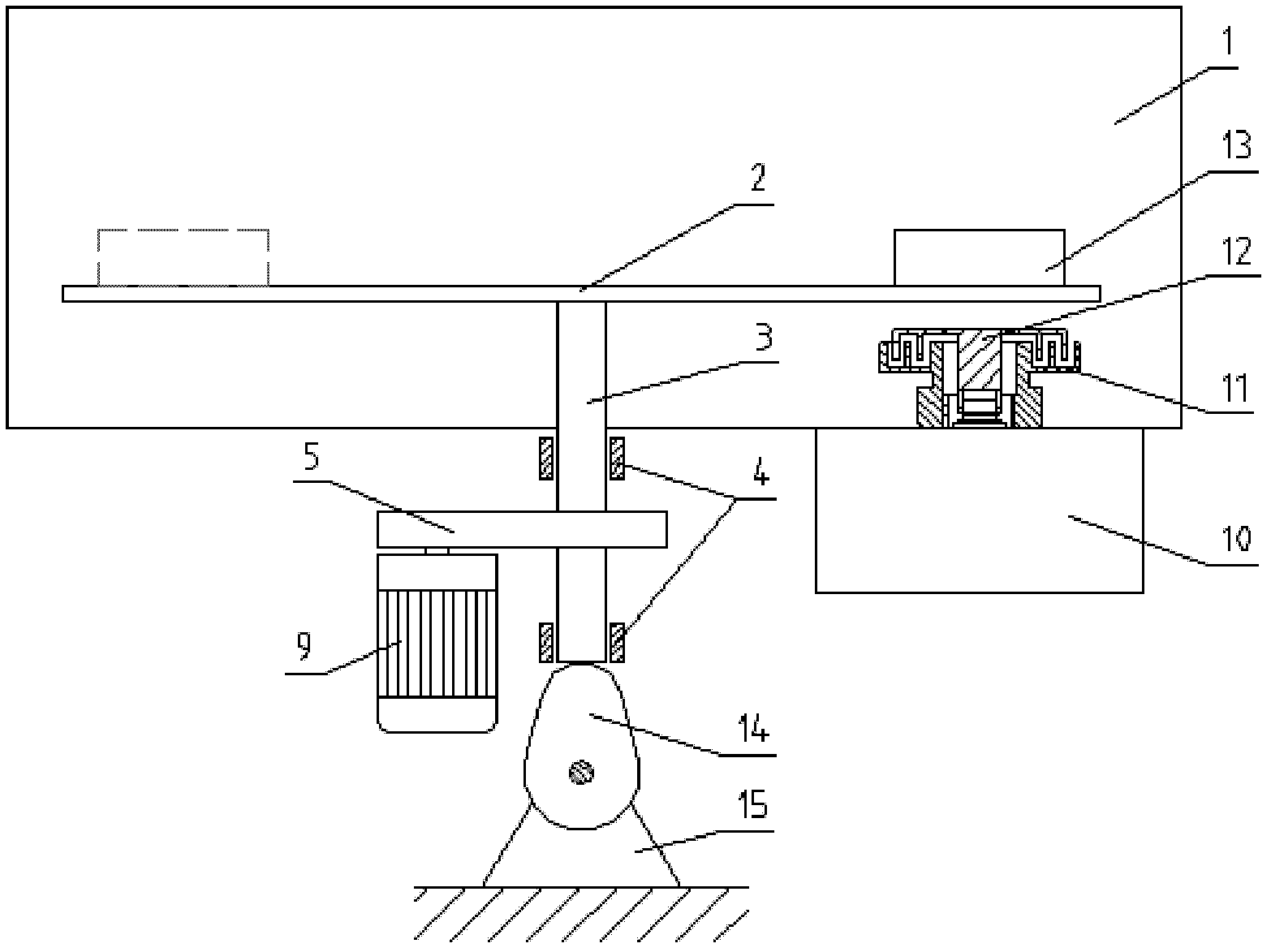

[0032] Gravimetric water vapor transmission rate test device, Figure 1-Figure 9Among them, it includes five parts: weighing device 10, moisture-permeable cup bracket 2, automatic lifting device, automatic rotating device 5 and environmental chamber 1. One end of the moisture-permeable cup bracket 2 is fixed together with the automatic lifting device and the automatic rotation device 5 through the connection mechanism 3. There is a through hole on the moisture-permeable cup bracket 2, and the moisture-permeable cup 13 is placed in the through hole of the moisture-permeable cup bracket 2. above. The connection between the collection part 12 and the environmental cavity 1 adopts a labyrinth seal design, the collection part 12 cooperates with the labyrinth seal part 11 , and the weighing device 10 is connected with the collection part 12 . The height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com