Hydrogen sulfide electrochemical transducer

An electrochemical and sensor technology, applied in the field of H2S electrochemical sensors, can solve the problems of methanol interference, complexity, and inability to restore sensor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

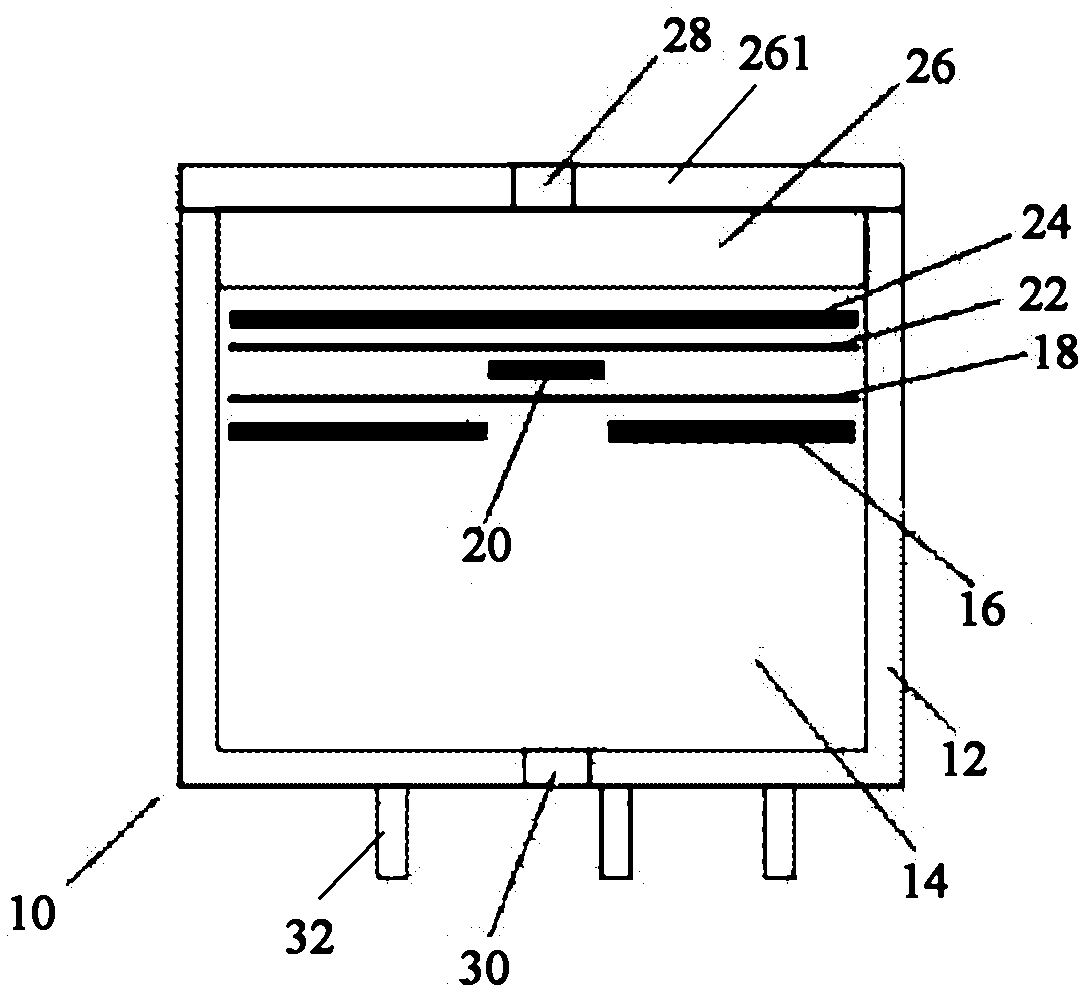

[0060] The manufacture of the sensor is the same as the preparation method in US Patent No. 4,042,464 to prepare the Au / C electrode; then the prepared Au / C electrode is added to the polytetrafluoroethylene emulsion and mixed, and the noble metal catalyzed porous electrode made after appropriate heat treatment is used as Working electrode, reference electrode and counter electrode; configure 3-12M H 2 SO 4 solution as the electrolyte; according to figure 1 The structure shown is equipped with a hydrogen sulfide sensor, and the diameter of the diffusion hole is 2-3 mm.

[0061] The obtained sensor was aged for 7 days under the condition that the working electrode was 0mV relative to the reference electrode, and then the potential of the working electrode relative to the reference electrode was set to 0mV and the following performance tests were performed:

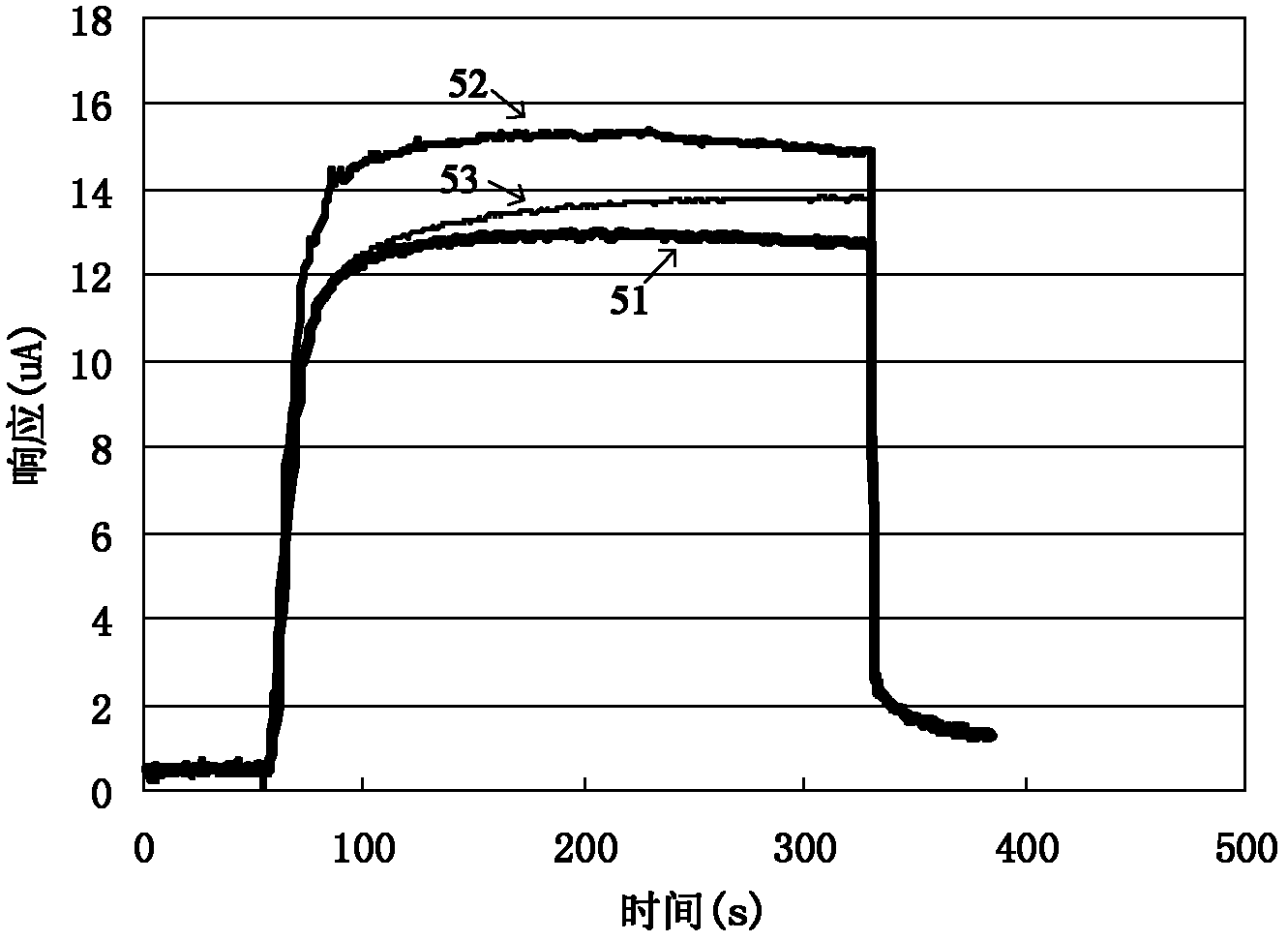

[0062] a) Use 25ppm (v / v) of H 2 S gas is measured with the above sensor, and the results are as follows image 3 As sh...

experiment example 2

[0065] Prepare the working electrode as in Experimental Example 1; then add Pt-Ru / C to the polytetrafluoroethylene emulsion and mix, and use the noble metal catalytic porous electrode made after appropriate heat treatment as the reference electrode and the counter electrode; configure 3-12M h 2 SO 4 solution as the electrolyte; according to figure 1 The structure shown is equipped with a hydrogen sulfide sensor, and the diffusion hole has a pore size of 2.7 mm.

[0066] The obtained sensor was aged for 7 days under the condition that the working electrode was 0mV relative to the reference electrode, and then the potential of the working electrode relative to the reference electrode was set to 0mV and the following performance tests were performed:

[0067] a) Use 25ppm (v / v) of H 2 S gas is measured with the above sensor, and the results are as follows image 3 As shown in the curve 52, the measurement sensitivity is 0.58μA / ppm, the T90 is 26s, and the resolution is 0.1ppm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com