Method for testing performance of semiconductor microwave power chip packaging shell

A microwave power and chip packaging technology, which is applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of inability to evaluate the microwave parameters of the package, high cost, and inability to truly reflect the performance of the package. Test efficiency, reduce production costs, and improve the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

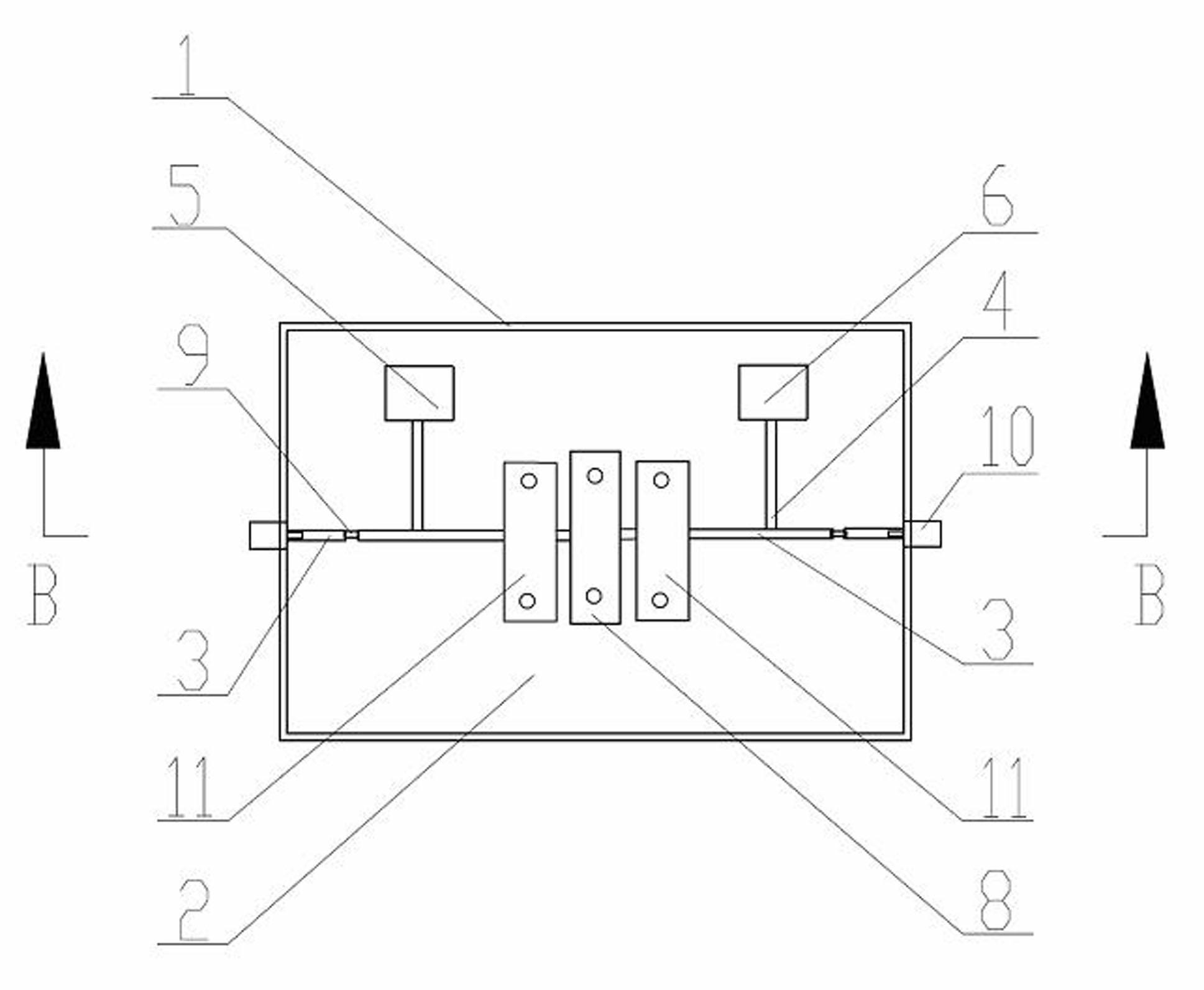

[0032] Depend on Figure 1 to Figure 5 It can be seen from the shown that: a method for testing the performance of semiconductor microwave power chip package shell, comprising the following steps:

[0033] 1) Prepare the microwave test module and the DC bias module, and adjust the two modules to the test state;

[0034] In this embodiment, the model of DC bias module B is N5770A, and the model of microwave test module D is N5242A. Set the test frequency and input power of the microwave test module D, and modulate the test frequency of the microwave test module D to 50MHz-26GHz.

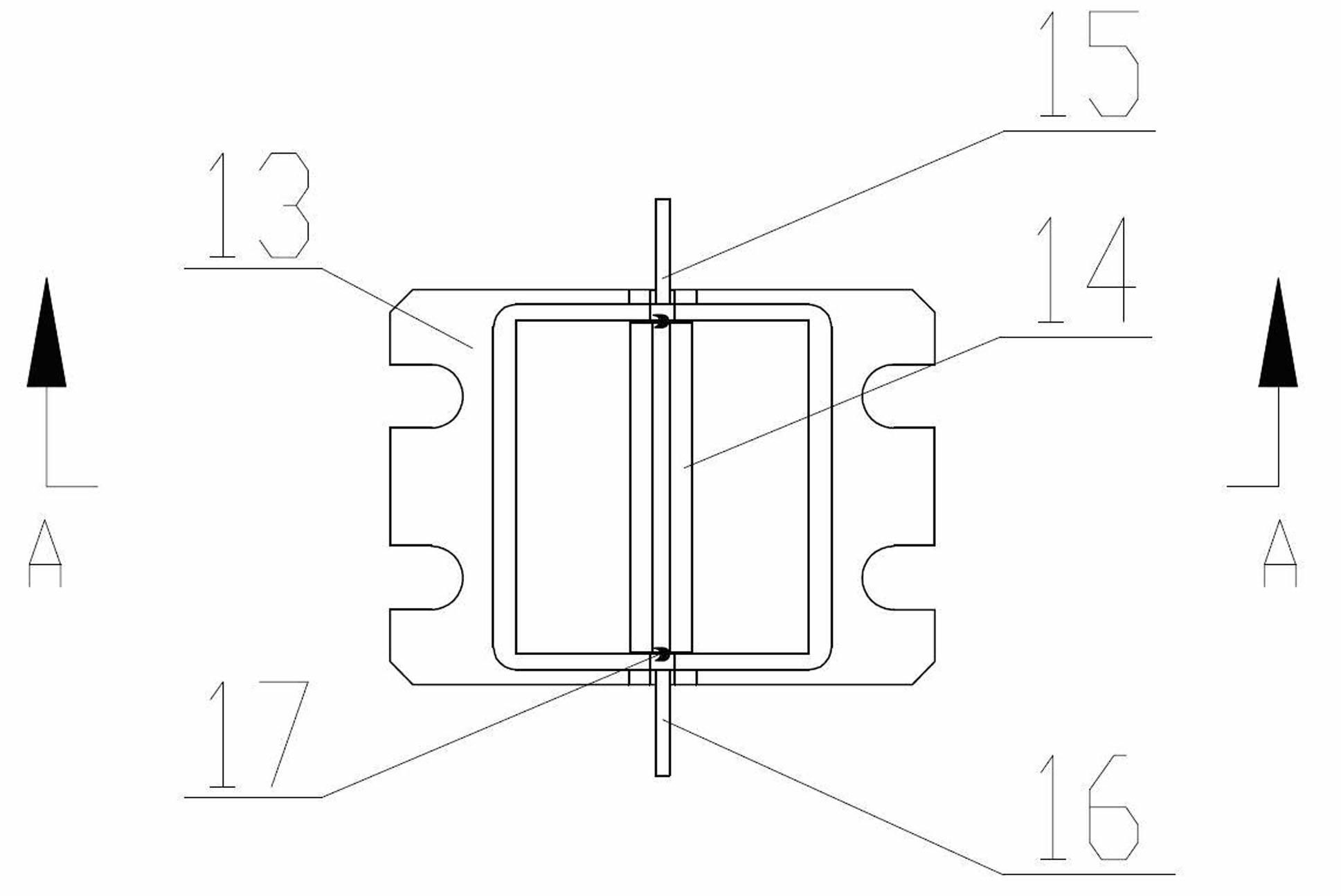

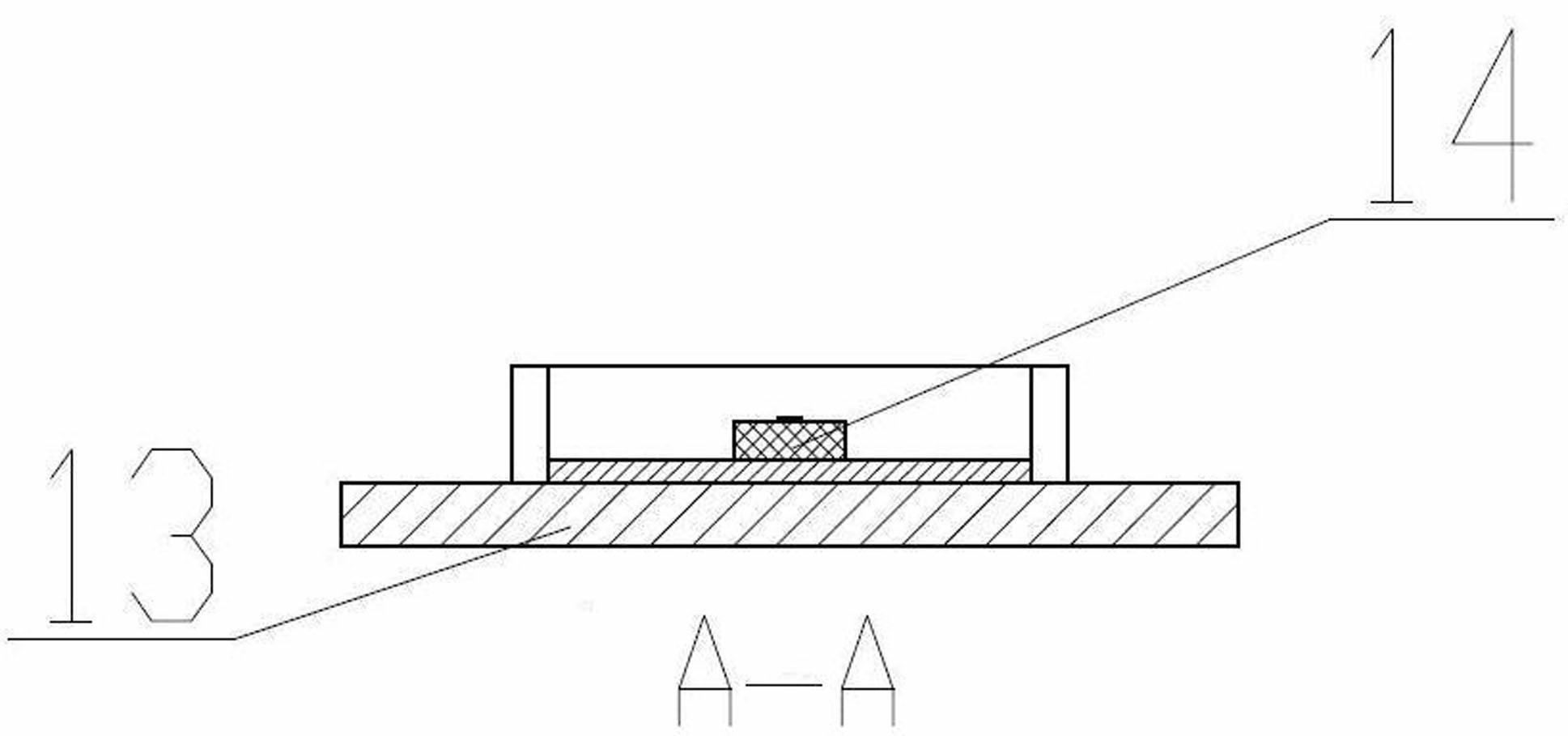

[0035] 2) Make the ceramic dielectric substrate microstrip circuit 14, and test the microwave performance parameter 1 of the ceramic dielectric substrate microstrip circuit 14 with the microwave test module in the above step 1);

[0036] The microwave test module D is used to test the performance of the ceramic dielectric substrate microstrip circuit 14 and record the microwave performance parameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com