Efficient energy-saving amorphous iron core transformer

An amorphous iron core, high-efficiency and energy-saving technology, applied in the field of transformers, can solve the problems of reduced heat dissipation area of the wire package, overheating damage, sparking, etc., and achieve the effects of reduced volume, high frequency, and convenient and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings.

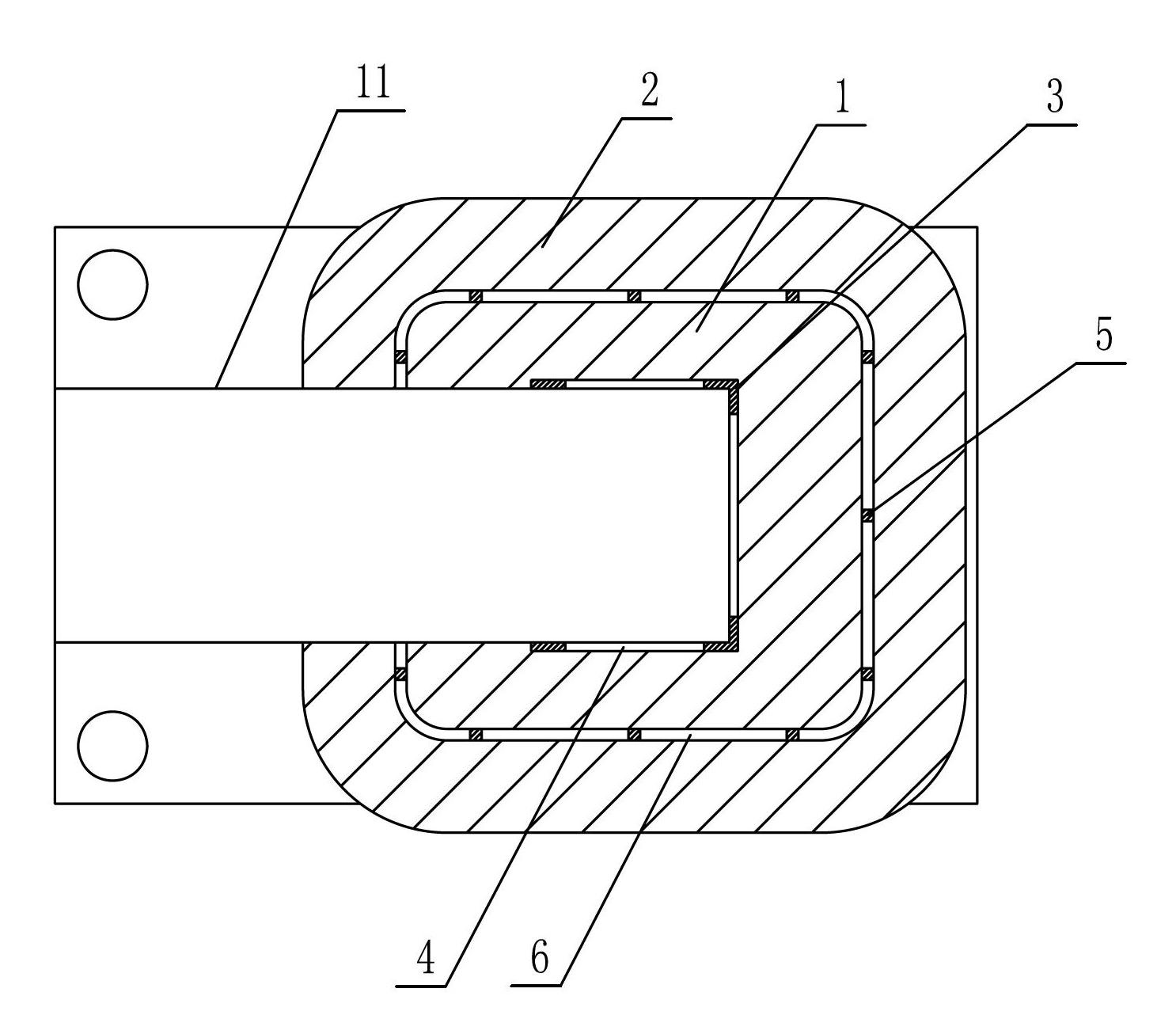

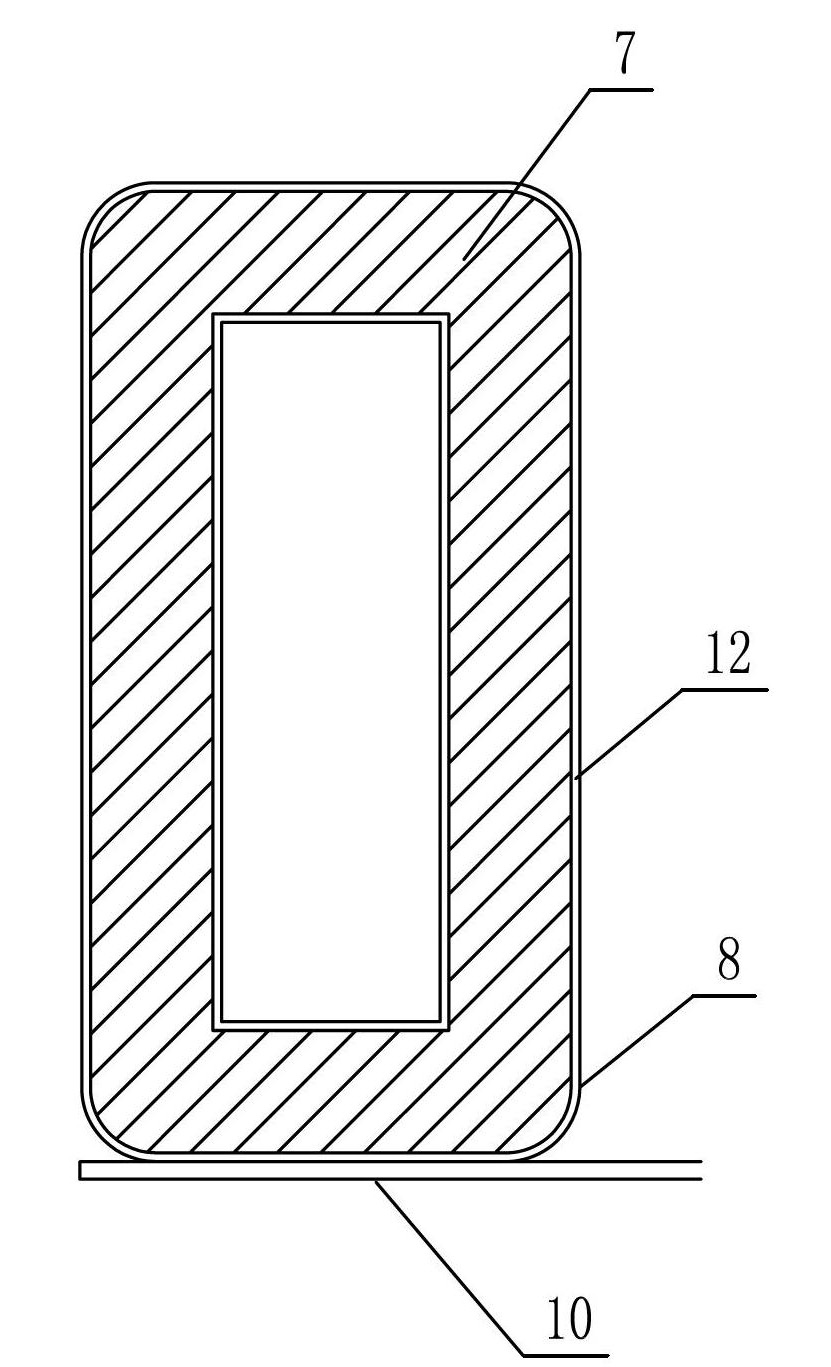

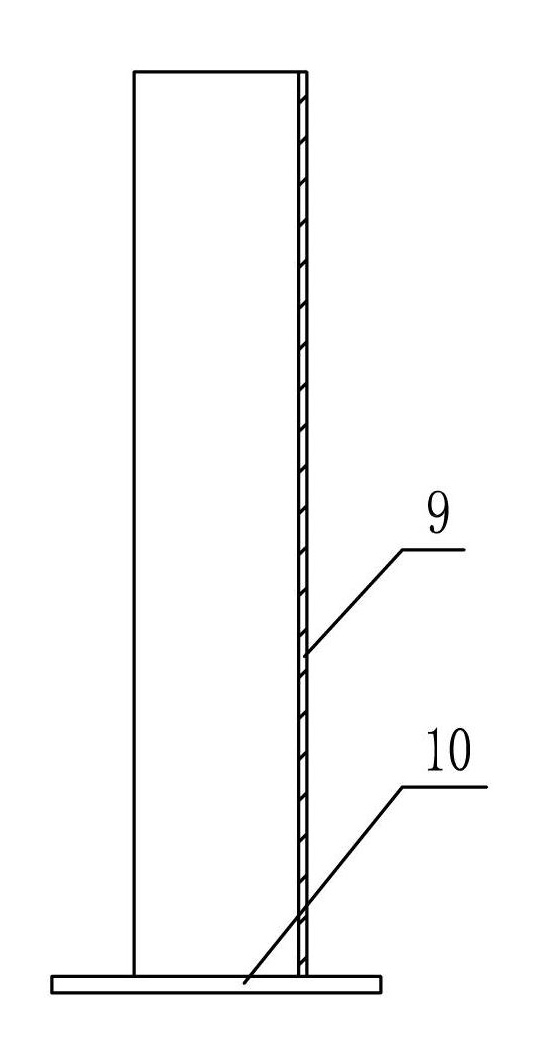

[0017] Such as Figure 1 ~ Figure 3 Shown: High-efficiency and energy-saving amorphous iron core transformer includes primary winding 1, secondary winding 2, epoxy brace 3, primary oil passage 4, epoxy stay 5, secondary oil passage 6, amorphous iron core 7, Protective box 8, epoxy cover plate 9, mounting plate 10, iron core assembly 11, silicone rubber 12, etc.

[0018] Such as figure 1 As shown, the present invention includes an iron core assembly 11, on which the primary winding 1 and the secondary winding 2 are sequentially wound, and an epoxy bracing 3 is arranged between the iron core assembly 11 and the primary winding 1 to form a primary oil passage 4. Epoxy stays 5 are set between the primary winding 1 and the secondary winding 2 to form the secondary oil passage 6; the primary oil passage 4 and the secondary oil passage 6 improve the heat dissipation effect, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com