High-speed multifunctional ball electric spindle

A multi-functional, electro-spindle technology, used in clamping, supporting, positioning devices, etc., can solve the problems of reducing the temperature of the spindle, single function, affecting the force of the tie rod, etc., to meet the requirements of high-precision machining, accurate tool position, ensure The effect of safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

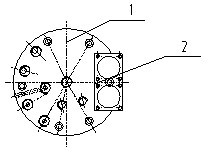

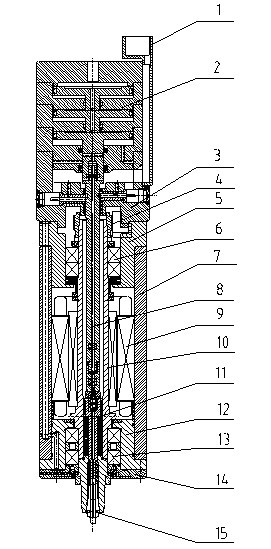

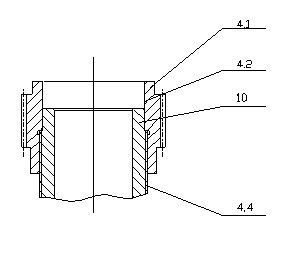

[0041] like Figure 1 to Figure 13 As shown in each figure, the present invention has a cylinder assembly (2), the top side of the cylinder assembly (2) cylinder top cover (2.1) is provided with a wire groove (1), and the piston of the cylinder assembly (2) is pushed out. The rod assembly (8), the bottom of the cylinder assembly (2) is fixed with an aluminum water jacket assembly (3), the inner through hole of the aluminum water jacket assembly (3) is provided with an encoder (4), and the bottom of the aluminum water jacket assembly (3) is fixed There is an upper bearing seat (5), and an upper bearing assembly (6) is arranged inside the upper bearing seat (5), the organic body assembly (7) is fixed at the bottom of the upper bearing seat (5), and the motor stator (9) is arranged inside the body assembly (7). ), the shaft core assembly (10) is provided at the axial through hole of the motor stator (9), and the shaft core assembly (11) is provided in the through hole in the midd...

Embodiment 2

[0043] Same as Example 1, except that the cylinder top cover (2.1), cylinder block (2.3), and the bottom of the cylinder block (2.3) are fixed on the top of the aluminum water jacket (2.7), and the cylinder body protrusion (2.6) is embedded in aluminum In the groove on the top of the water jacket (2.7), a sealing ring is provided at the edge and inner wall contact between the cylinder body (2.3) and the aluminum water jacket (2.7). The first-stage piston (2.2), the middle part of the inner chamber of the cylinder block (2.3) directly below the first-stage piston (2.2) is provided with the second-stage piston (2.4), and the inner chamber of the cylinder block (2.3) directly below the second-stage piston (2.4) The lower part is provided with a three-stage piston (2.5), and seal rings are provided at the contact points between the first-stage, two-stage and three-stage pistons and the inner chambers of the cylinders at all levels.

Embodiment 3

[0045] Same as Example 1, except that the inner cavity of the main body of the aluminum water jacket (3.1) is provided with an inner cavity seat through which the shaft of the push rod (3.5) penetrates, and the inner side of the inner cavity seat is radially provided with a release knife Proximity switch (3.3), the interior of the inner cavity seat is also radially provided with a broach proximity switch (3.6); the outer wall of the main body of the aluminum water jacket where the loose knife proximity switch (3.3) and the broach proximity switch (3.6) are located It is blocked by a cross-recessed plug assembly (3.4); the loosening knife proximity switch (3.3) and the broaching knife proximity switch (3.6) are fixed in the inner cavity seat by an axial set screw (3.2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com