Preparation method of ZSM-35 molecular sieve

A ZSM-35, molecular sieve technology, applied in the direction of iron conglomerate crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of increasing synthesis cost, increasing environmental treatment cost, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Add 46.9g H in a 100ml beaker 2 O, add 7.8g sodium aluminate under stirring condition, dissolve. Add 735g of cyclohexylamine into a 2L round bottom flask, add the above-mentioned sodium aluminate solution, stir for 60 minutes, add 78.33g of fumed silica within 30 minutes, continue stirring for 120 minutes, then add 3.9g of ZSM- 35 molecular sieve seed crystals, continue to stir for 30 minutes, transfer to a 1L high-pressure reactor, and the above stirring speed is 200 rpm.

[0037] The temperature was raised to 185° C. within 6 hours, and then the reaction was stirred at a speed of 200 rpm for 12 hours. The reactor was taken out and cooled to room temperature, and the solid sample was filtered out. The solid sample was directly placed in a vacuum oven at 50°C for 24 hours to obtain the raw molecular sieve powder.

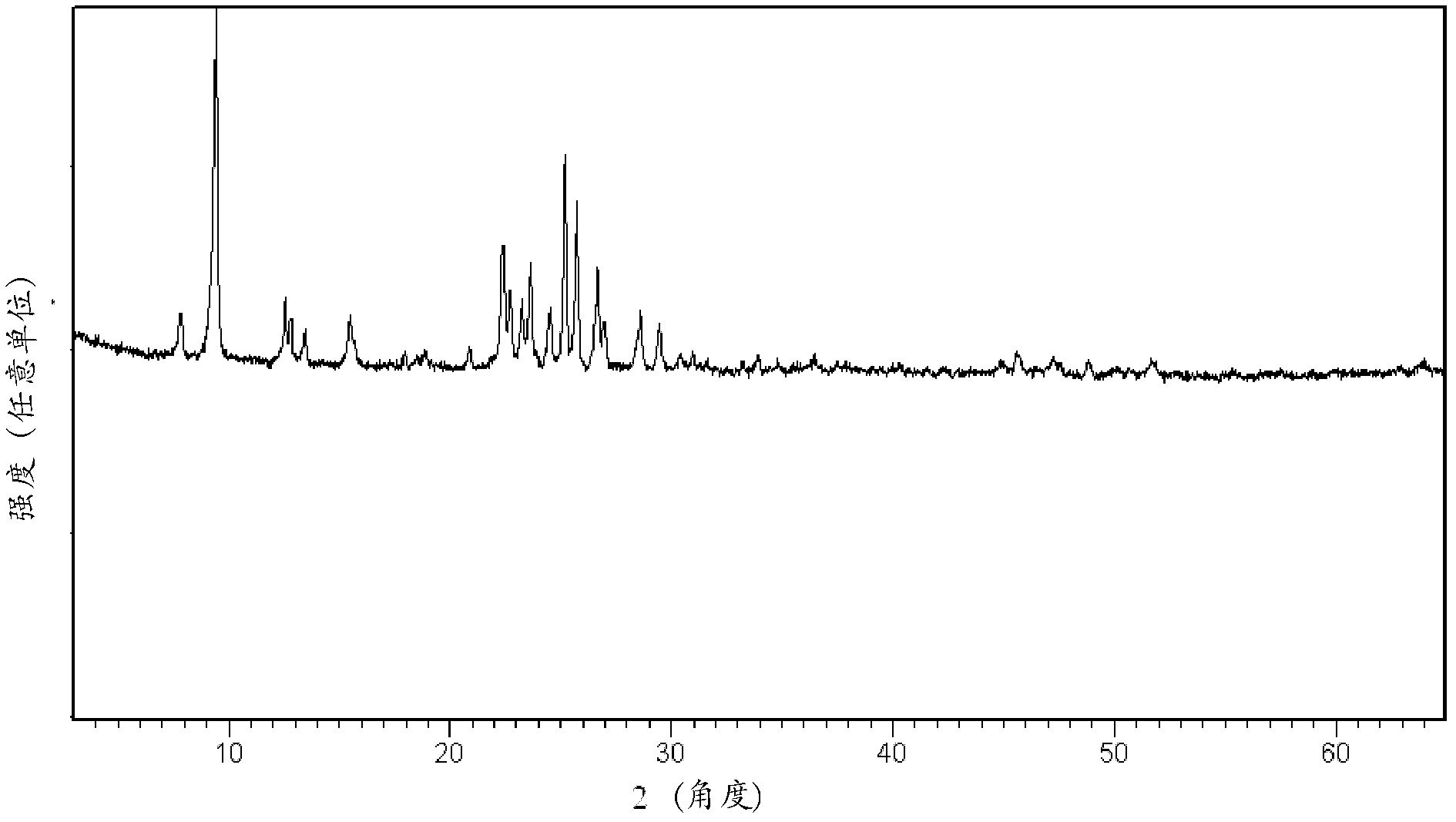

[0038] The XRD spectrum of the obtained sample is as figure 1As shown, its crystal phase is consistent with the molecular sieve obtained by the hydrotherm...

Embodiment 2

[0040] Add 46.9g H in a 100ml beaker 2 O, add 7.8g sodium aluminate under stirring condition, dissolve. Add 735g of cyclohexylamine into a 2L round bottom flask, add the sodium aluminate solution configured above, stir for 60 minutes, then add 78.33g of fumed silica within 30 minutes, continue stirring for 120 minutes and then directly transfer to 1L High-pressure reactor, the above stirring speed is 250 rpm.

[0041] The temperature was raised to 185° C. within 6 hours, and then the reaction was stirred at a speed of 250 rpm for 96 hours. The reactor was taken out and cooled to room temperature, and the solid sample was filtered out. The solid sample was directly placed in a vacuum oven at 50°C for 24 hours to obtain the original molecular sieve powder.

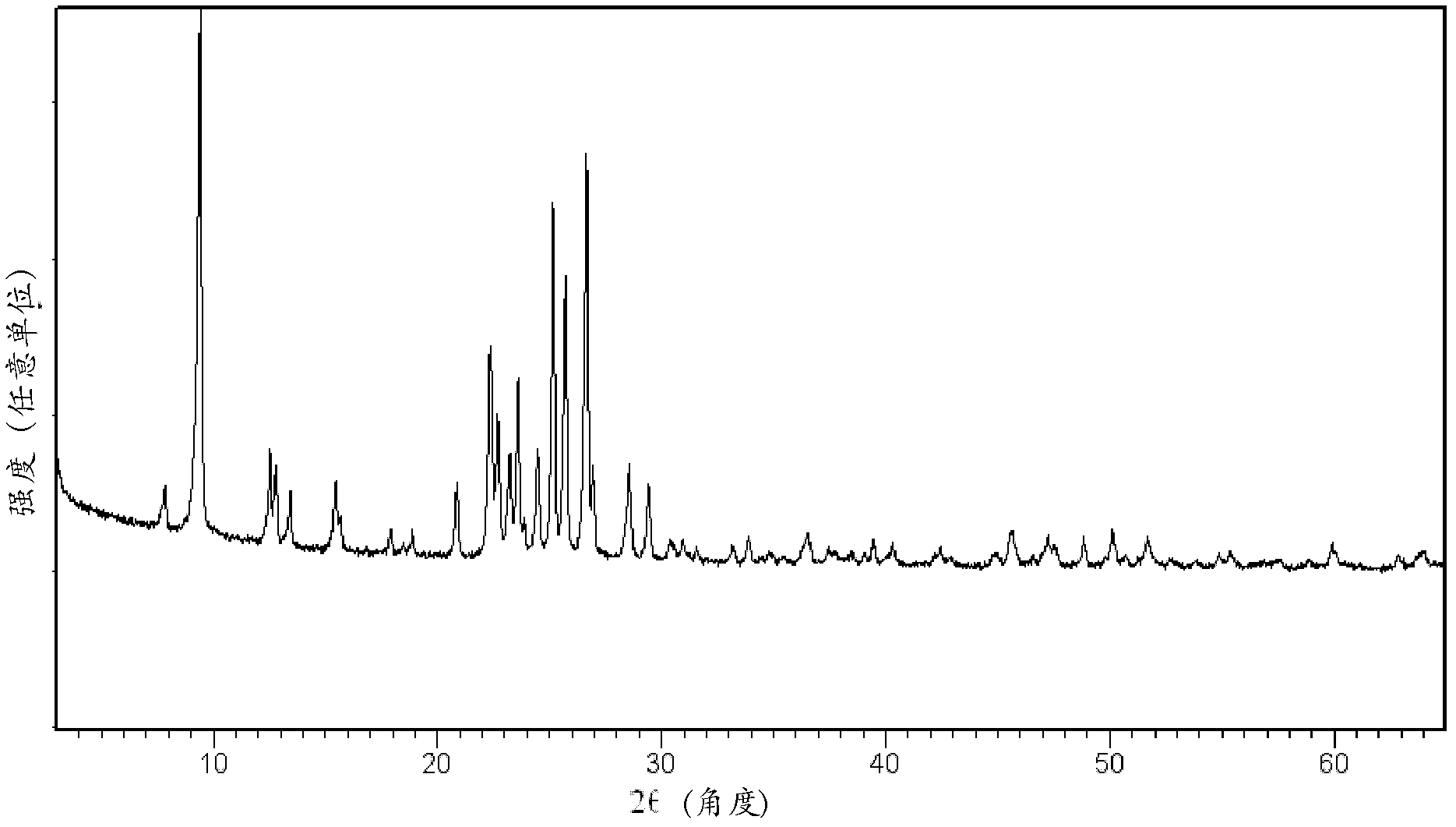

[0042] The XRD spectrum of the obtained sample is as image 3 As shown, its crystal phase is consistent with the molecular sieve obtained by the hydrothermal synthesis method in the prior art, showing a typical FER struct...

Embodiment 3

[0044] Add 72.4g H to a 100ml beaker 2 O, add 10.2g sodium aluminate under stirring condition, dissolve. Add 735g of cyclohexylamine into a 2L round bottom flask, add the above-mentioned aluminum sulfate solution, stir for 60 minutes, add 86.1g of 400 mesh finely ground silica gel powder within 30 minutes, and continue stirring for 120 minutes. Then 3.4g NaOH was dissolved in 7g H 2 O was added dropwise to the above reaction system, and then 15.6g of ZSM-35 molecular sieve seed crystals were added, and the stirring was continued for 30 minutes, and then transferred into a 1L high-pressure reactor, and the above stirring speeds were all 300 rpm.

[0045] The temperature was raised to 185° C. within 6 hours, and then the reaction was stirred at a speed of 300 rpm for 72 hours. The reactor was taken out and cooled to room temperature, and the solid sample was filtered out. The solid sample was directly placed in a vacuum oven at 50°C for 24 hours to obtain the original molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com