Method for preparing magnesium-aluminum hydrotalcite

A hydrotalcite and magnesium-aluminum technology, which is applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of high product cost and restrictions on the promotion and application of materials, and achieve low production cost, which is conducive to environmental improvement and protection, and has no The effect of three waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

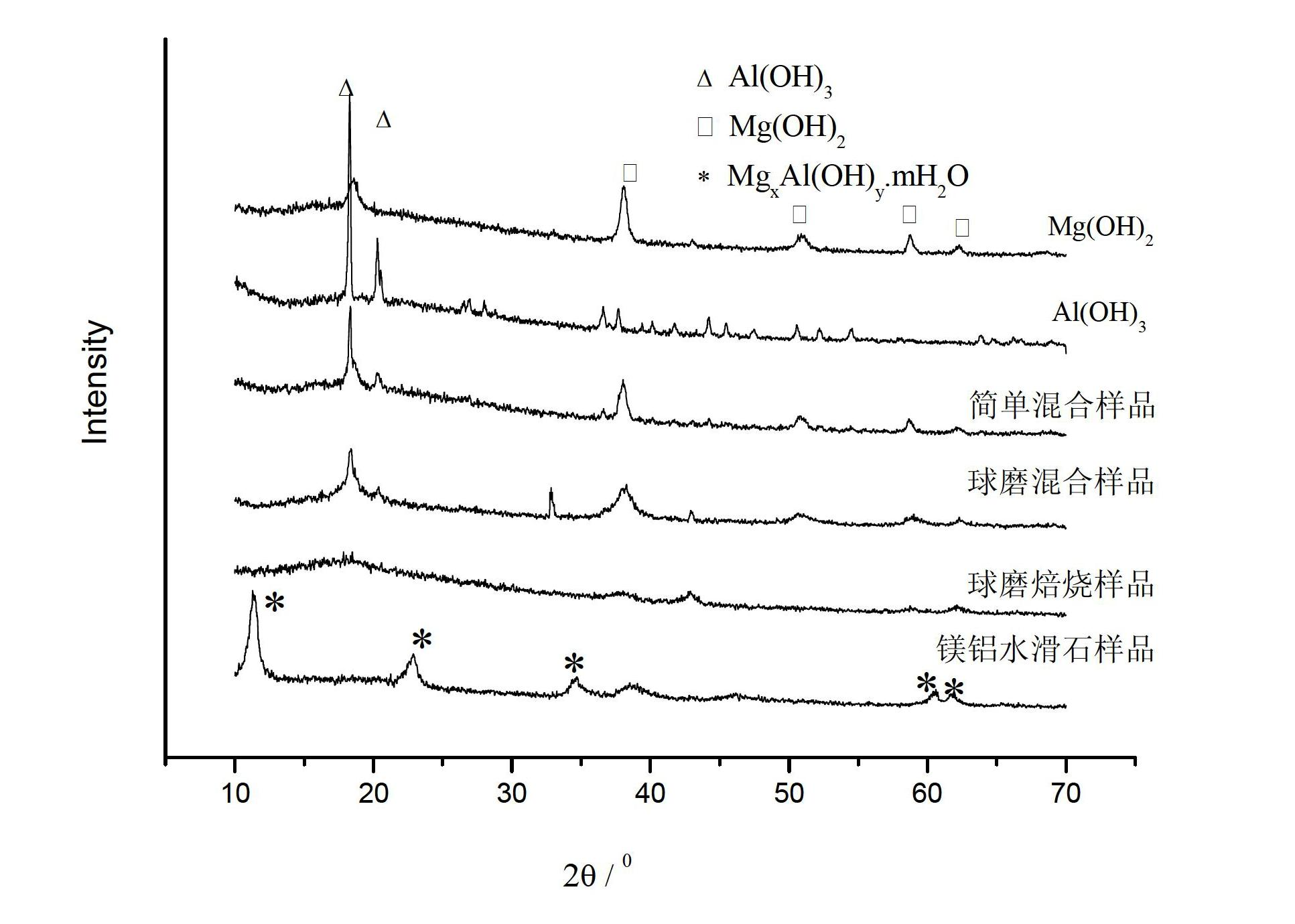

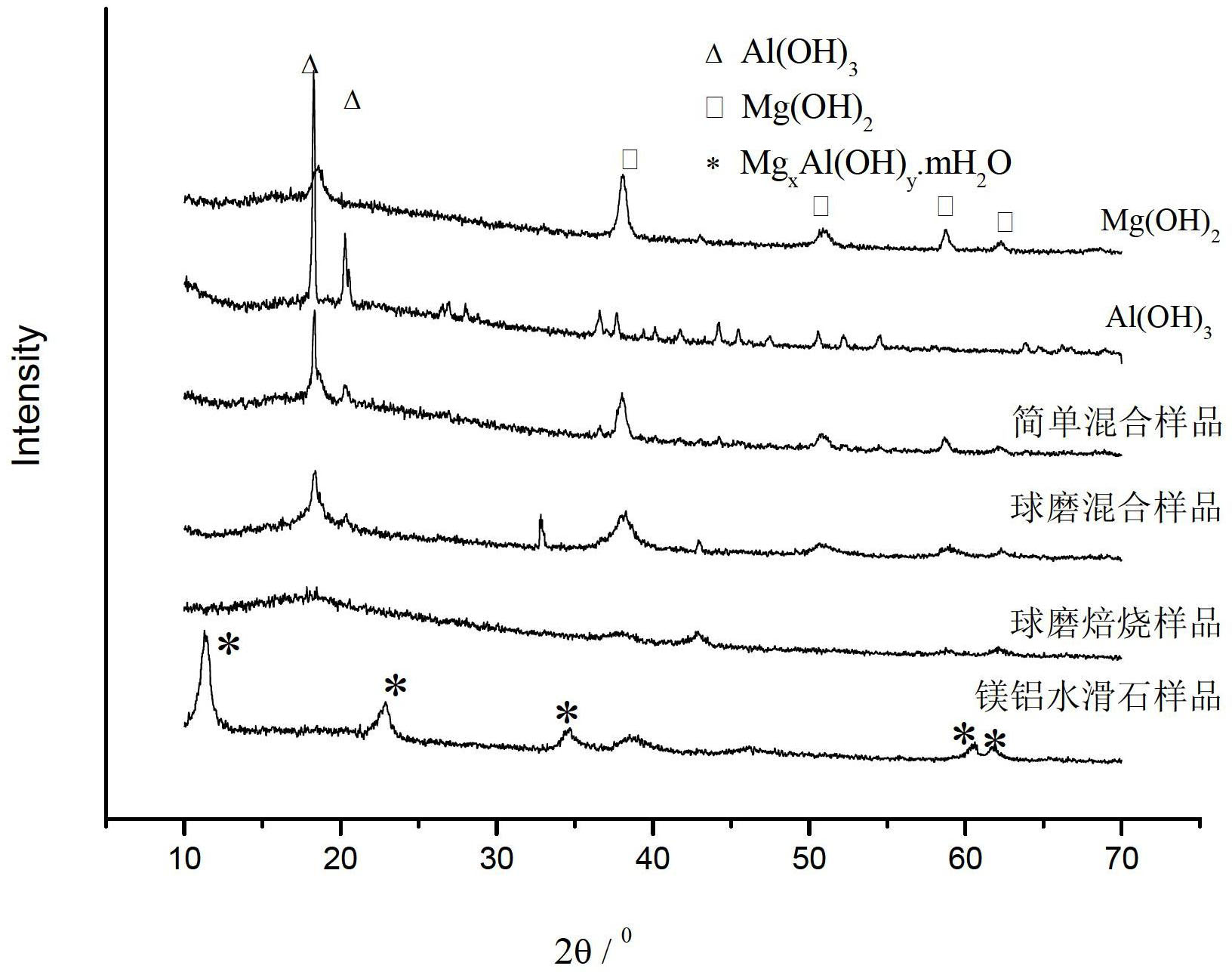

Image

Examples

Embodiment 1

[0016] 1) Mix magnesium hydroxide and gibbsite at a molar ratio of 3:1;

[0017] 2) Put the above mixture into a high-speed ball mill and mill for 3 hours, wherein the mass ratio of the mixture to the steel balls of the ball mill is 1:3; the steel balls of the ball mill are steel balls with a particle size of 4 mm and steel balls with a particle size of 6 mm, of which 4 mm steel balls The mass ratio of the ball to the 6mm steel ball is 3:7;

[0018] 3) Put the ground mixture in a muffle furnace and bake it at 450°C for 3 hours to obtain a uniformly dispersed magnesium-aluminum mixed oxide;

[0019] 4) Add the above-mentioned magnesium-aluminum mixed oxide to 3 times the mass of water at 50°C, and react for 26 hours to obtain magnesium-aluminum hydrotalcite.

Embodiment 2

[0021] 1) Mix magnesium hydroxide and gibbsite at a molar ratio of 5:1;

[0022] 2) Put the above mixture into a high-speed ball mill and mill for 5 hours, wherein the mass ratio of the mixture to the steel balls of the ball mill is 1:3; The mass ratio of the ball to the 6mm steel ball is 3:7;

[0023] 3) Put the ground mixture in a muffle furnace and bake it at 550°C for 3 hours to obtain a uniformly dispersed magnesium-aluminum mixed oxide;

[0024] 4) Add the above-mentioned magnesium-aluminum mixed oxide to 5 times the mass of water at 80°C, and react for 24 hours to obtain magnesium-aluminum hydrotalcite.

Embodiment 3

[0026] 1) Mix magnesium hydroxide and gibbsite at a molar ratio of 1:1;

[0027] 2) Put the above mixture into a high-speed ball mill and mill for 2 hours, wherein the mass ratio of the mixture to the steel balls of the ball mill is 1:3; the steel balls of the ball mill are steel balls with a particle size of 4 mm and steel balls with a particle size of 6 mm, of which 4 mm steel balls The mass ratio of the ball to the 6mm steel ball is 3:7;

[0028] 3) Put the ground mixture in a muffle furnace and bake it at 380°C for 5 hours to obtain a uniformly dispersed magnesium-aluminum mixed oxide;

[0029] 4) Add the above-mentioned magnesium-aluminum mixed oxide into water at 20° C. twice the mass, and react for 30 hours to obtain magnesium-aluminum hydrotalcite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com