Preparation method of polytetrafluoroethylene with high creep resistance

A technology of polytetrafluoroethylene and tetrafluoroethylene, which is applied in the field of preparation of high-strength creep-resistant polytetrafluoroethylene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

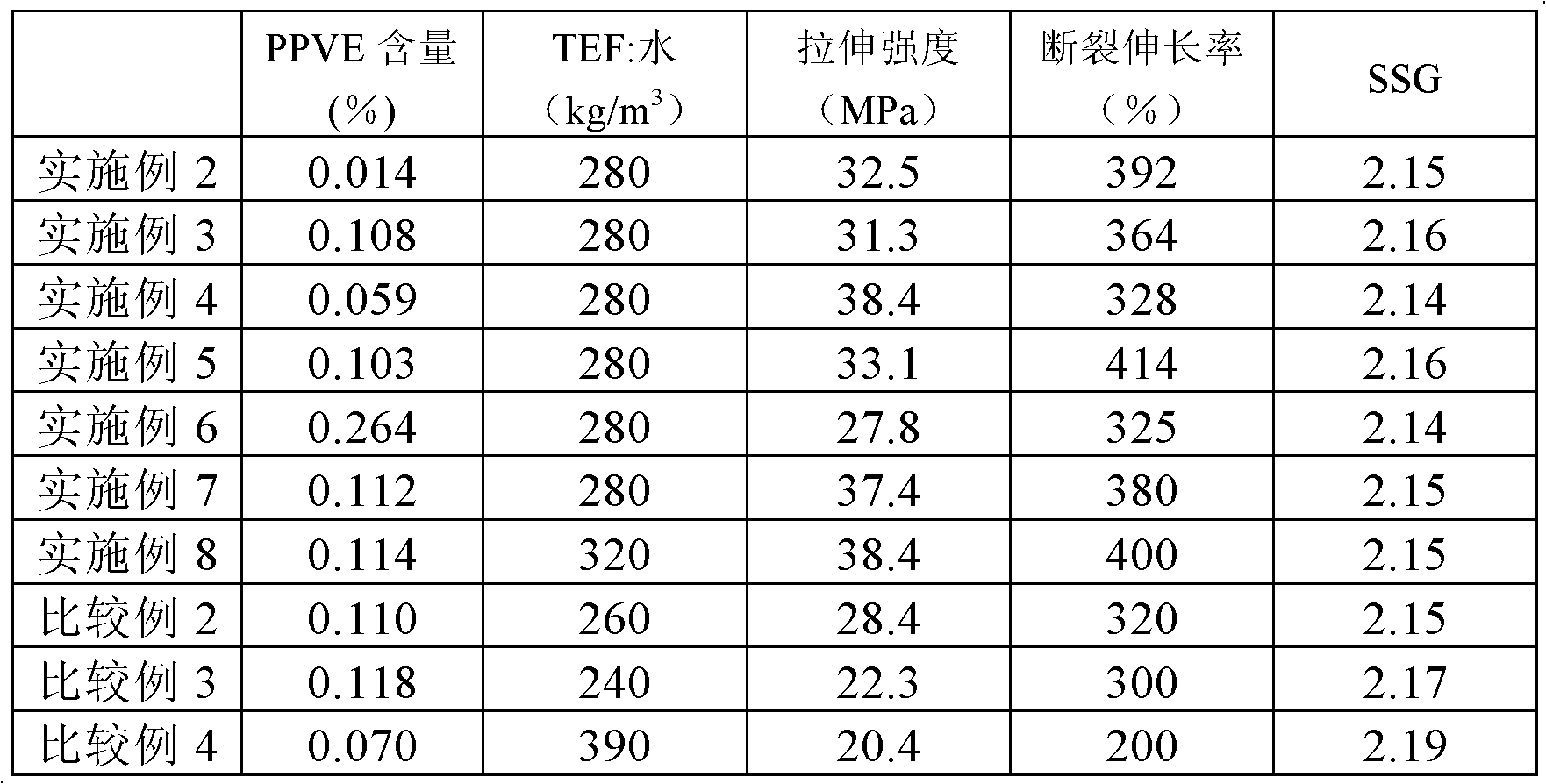

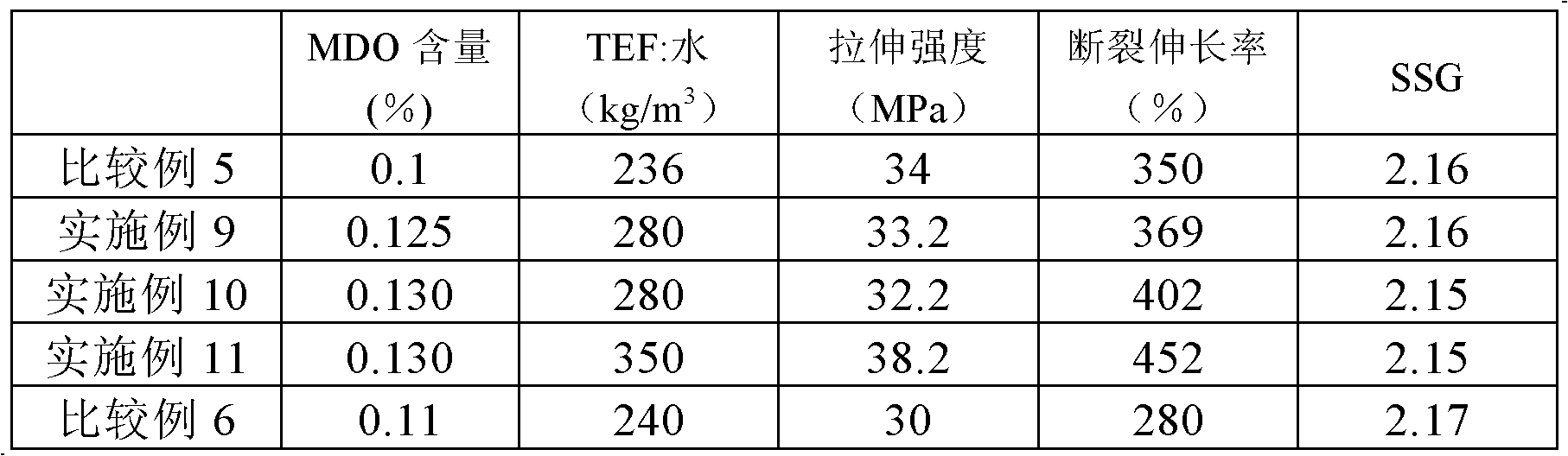

Examples

preparation example Construction

[0022] The invention provides a suspension preparation method of modified polytetrafluoroethylene, which does not use fluorine-containing surfactants (such as perfluorosurfactants). The method of the present invention comprises the step of adding all or part of the perfluoroalkyl vinyl ether and / or perfluorodioxole comonomer into a vacuumized reaction vessel filled with water.

[0023] The present invention uses water as the reaction medium for suspension polymerization. In the method of the present invention, water is first injected into the reaction vessel. The amount of water added is not particularly limited, and it can be a conventional amount used in the art, for example, it can account for 1 / 3 to 2 / 3 of the volume of the reaction vessel. In one example of the present invention, the volume of added water accounts for 3 / 5±10% of the volume of the reaction vessel.

[0024] To prevent oxygen from interfering with the polymerization reaction, the reaction vessel containing...

Embodiment

[0052] testing method

[0053] 1. Determination of the content of monomer units derived from perfluoropropyl vinyl ether in the copolymer

[0054] The amount of monomer units derived from perfluoropropyl vinyl ether in the samples was determined by infrared spectroscopy. The specific method is: press the sample particles to be tested into a transparent film, then put the film on the Fourier infrared spectrometer for analysis, and calculate the wave number from the obtained infrared spectrum to be 2365cm -1 and 994cm -1 The absorption peak intensity A, calculates the mass percentage content that is derived from the monomer unit of perfluoropropyl vinyl ether (PPVE) according to the following formula:

[0055] PPVE% (mass percentage) = (A994 / A2365) × 0.95

[0056] Among them, A994 is at 994cm -1 The intensity of the absorption peak at

[0057] A2365 is at 2365cm -1 The intensity of the absorption peak at .

[0058] 2. Determination of the content of monomer units de...

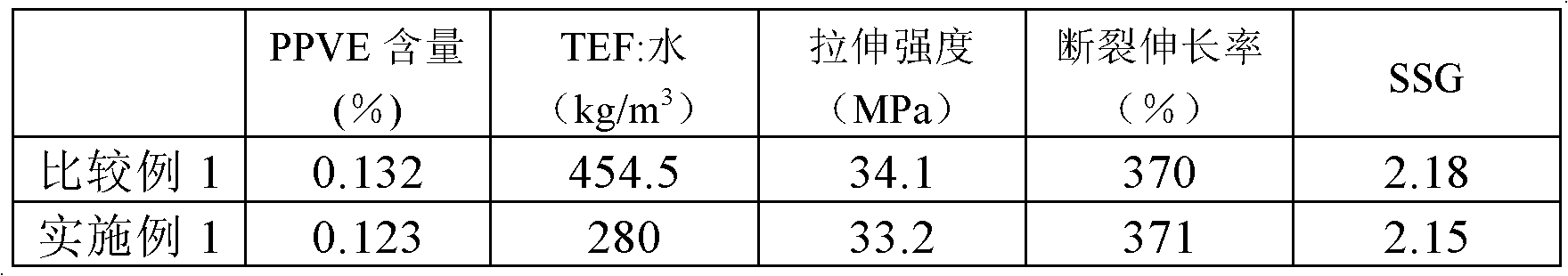

Embodiment 1

[0071] Inject 30 liters of deionized water into the 50-liter reactor, use high-purity nitrogen with a purity of 99.99% to repeatedly replace the air in the reactor for at least 3 times, and then check the oxygen content in the reactor until the oxygen content is lower than 30ppm, and the oxygen content is qualified Vacuumize the reactor to a vacuum degree of 0.06MPa and heat up to 75°C, vacuum inhale 40 grams of perfluoropropyl vinyl ether, add 5ml of ammonia water and 2 grams of potassium persulfate, and raise the pressure of the tetrafluoroethylene monomer in the kettle to To 1.2MPa, start stirring to start the reaction.

[0072] Control the ratio of the amount of tetrafluoroethylene monomer to the amount of deionized water to 280kg / m 3 , Keep the reaction temperature fluctuating within the range of 75±5°C during the reaction. After the reaction is finished, unreacted tetrafluoroethylene monomer is recovered, and the pressure inside the kettle is released to obtain fibrous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com