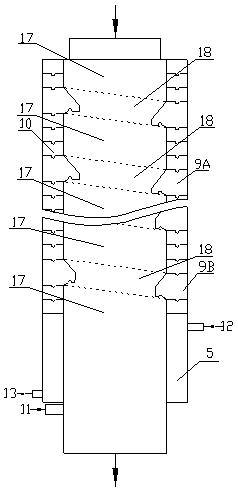

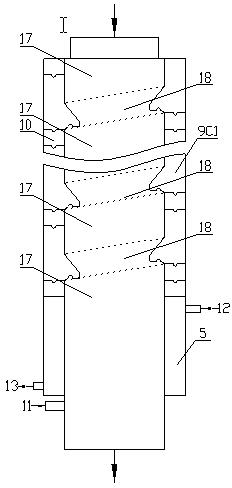

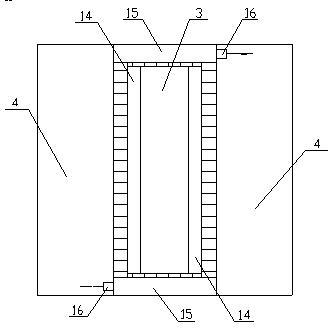

Coking chamber for pulverized coal destructive distillation

A technology of carbonization chamber and pulverized coal, which is applied in the field of carbonization chamber, can solve the problems of increased liquid seal height of liquid seal tank, large exhaust resistance of raw coal gas, and increased gas flow resistance, so as to improve heat energy utilization rate, shorten residence time, The effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described below.

[0026] The present invention is based on the prior art and based on the carbonization mechanism of pulverized coal. The pulverized coal forms a moving bed in the carbonization chamber, and the gaps between the particles of the moving bed form small, tortuous and interlinked complex passages through which air can pass. The flow resistance of fluid through complex channels is studied by mathematical model method. Among them, for N 2 , CO 2 There are many reports on gas resistance research, but for CH 4 、H 2 and CO gas resistance research reports are rare, the research group of the present invention deeply studied the main component of pyrolysis gas CH 4 、H 2 and CO and other gases, the following calculation model is established: ,in , , β is the correction coefficient.

[0027] It can be seen from the above formula that the pressure drop of the fluid passing through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com