Lifting mechanism for railway T-shaped girder bridge erecting machine

A technology of hoisting mechanism and bridge erecting machine, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc. It can solve the problems of reducing the replacement rate of wire ropes, hidden safety hazards, and difficulty in manually arranging ropes, so as to shorten maintenance time and facilitate Fault judgment and the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

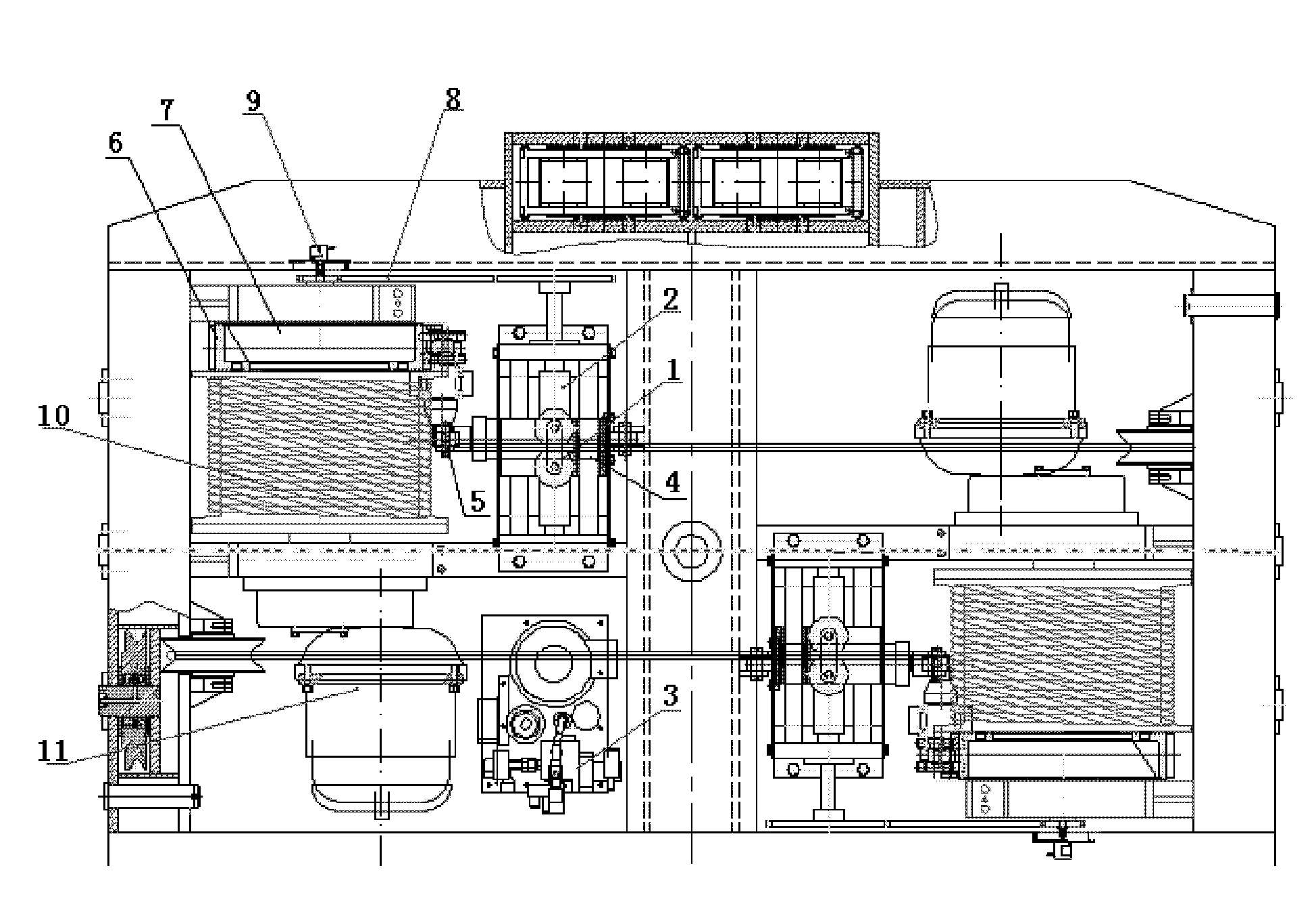

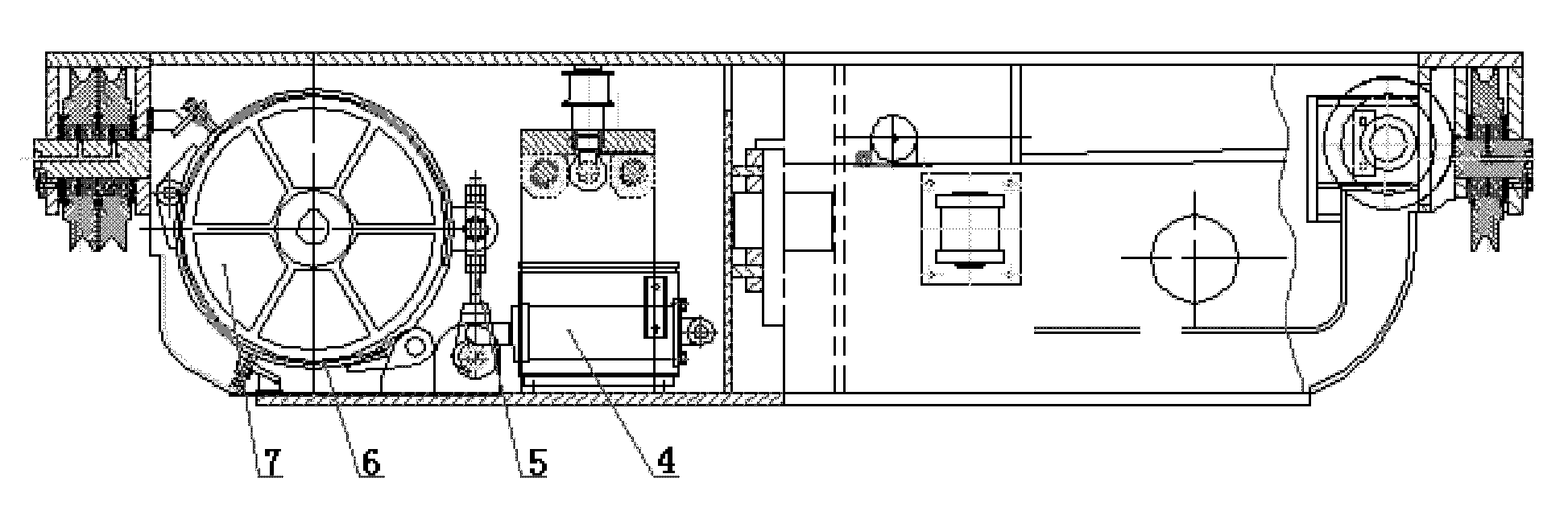

[0031] see figure 1 and figure 2 , shows the structure diagram of the suspension beam trolley of the railway T-beam bridge-erecting machine hoisting mechanism of the present invention, and the railway T-beam bridge-erecting machine hoisting mechanism of the present invention comprises at least one figure 1 The crane beam trolley shown preferably includes two crane beam trolleys, and the crane beam trolley includes at least one set of hoisting hoisting systems, preferably as shown in the figure, including two sets of symmetrically arranged hoisting hoisting systems, that is, preferably It can have four sets of hoisting hoisting systems to provide hoisting hoisting of four wire ropes.

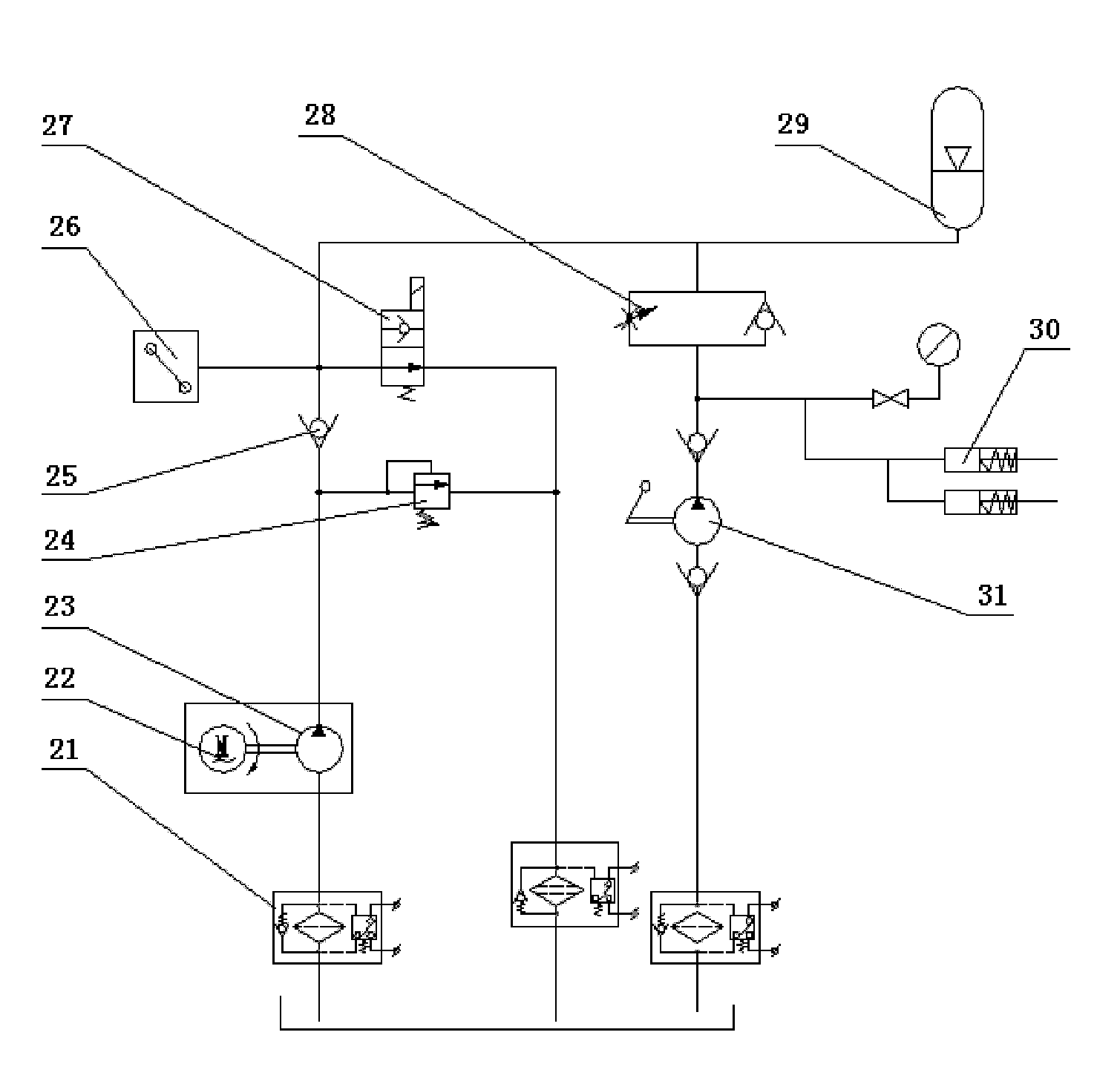

[0032] The hoisting winch system at least includes a power device, a planetary gear rope winding device, a double-helix mechanical rope pulling device, a final braking device, a hydraulic station 3 and a control system.

[0033]The power unit wherein includes hoisting motor 11 and deceleration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com