Optical fiber temperature sensor

An optical fiber temperature and sensor technology, used in thermometers, thermograms, thermometer components, etc., can solve the problem of inability to directly use optical fiber temperature monitoring devices, and achieve the effects of excellent insulation, easy exchange, and rust prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

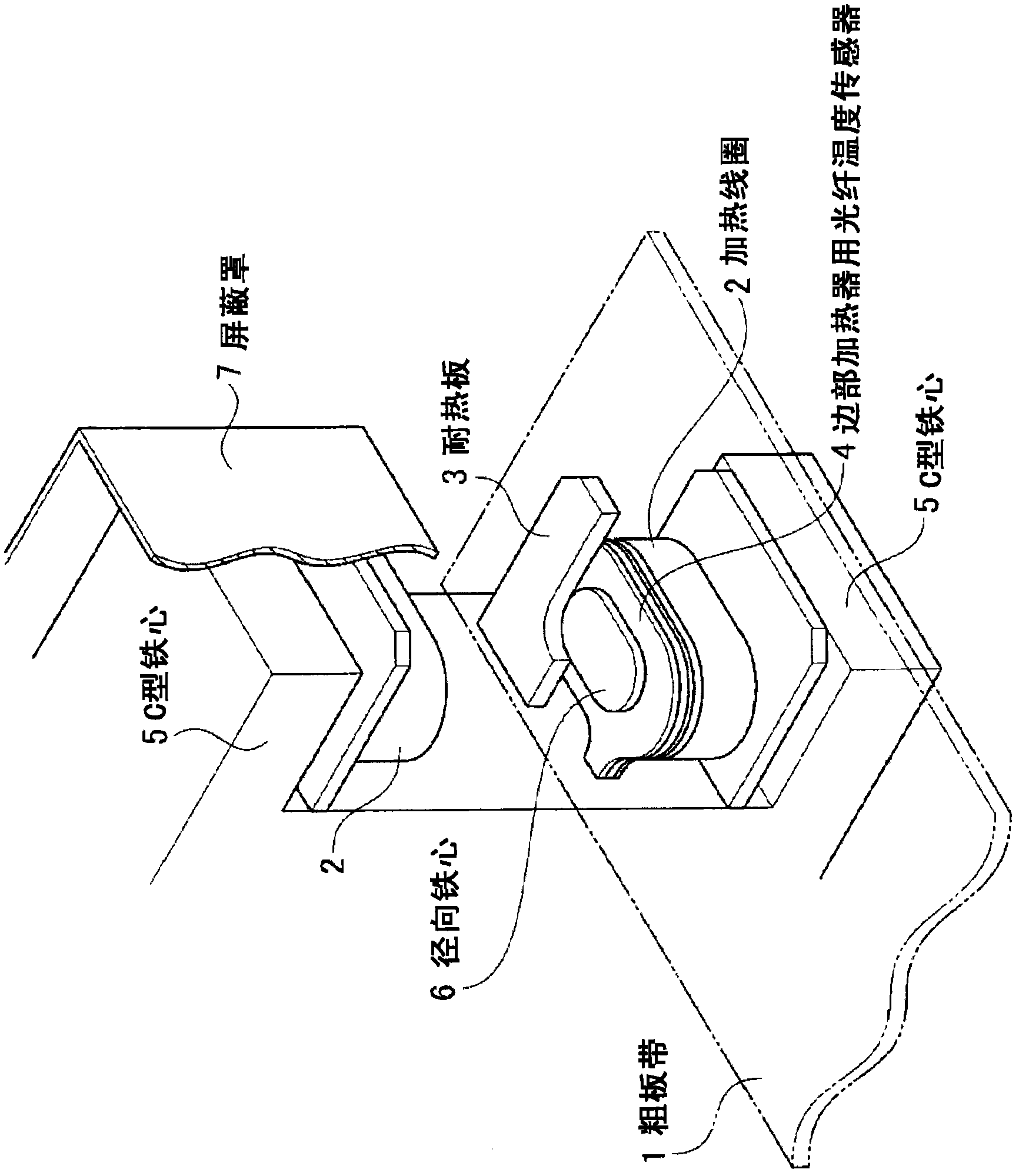

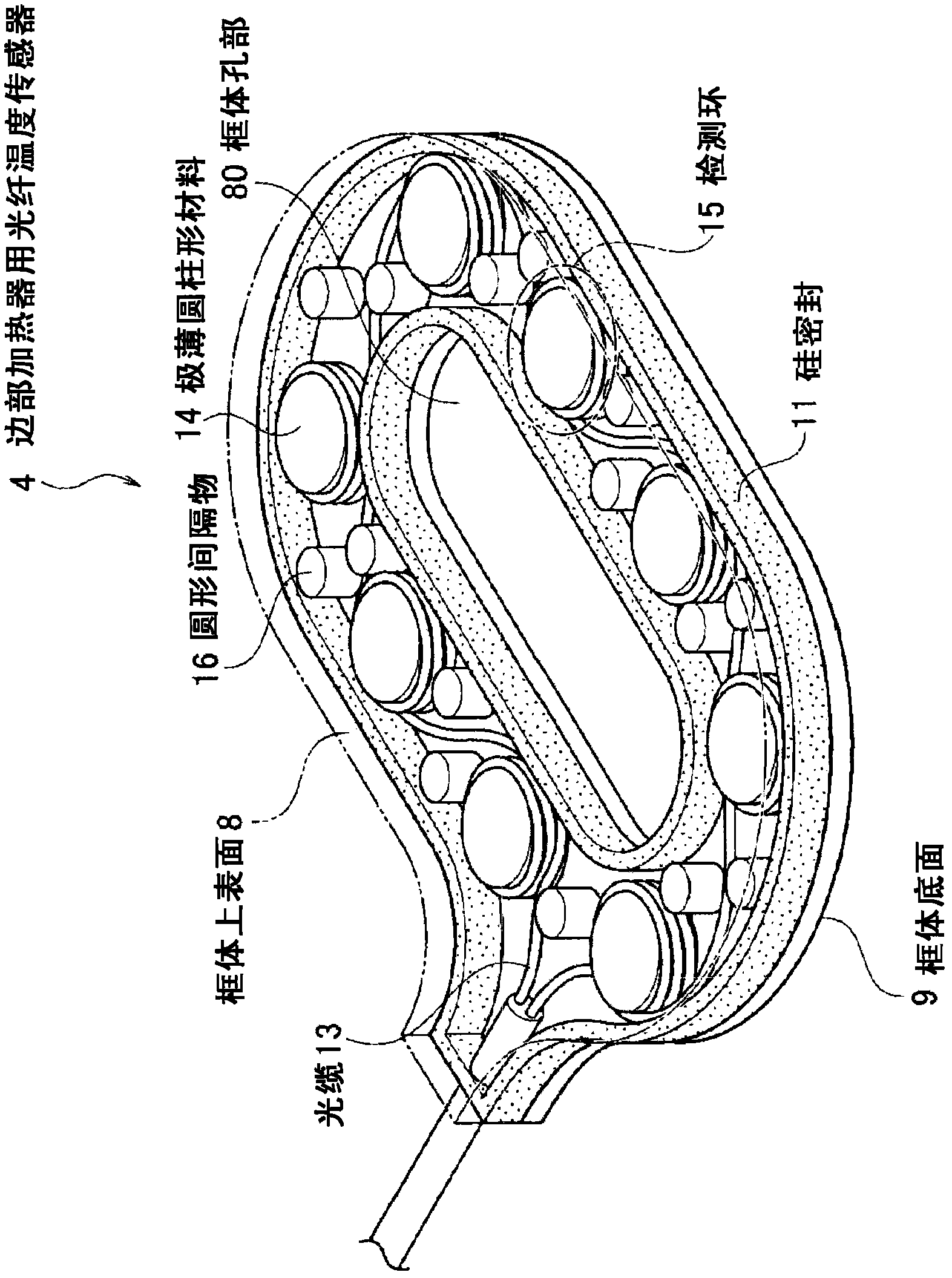

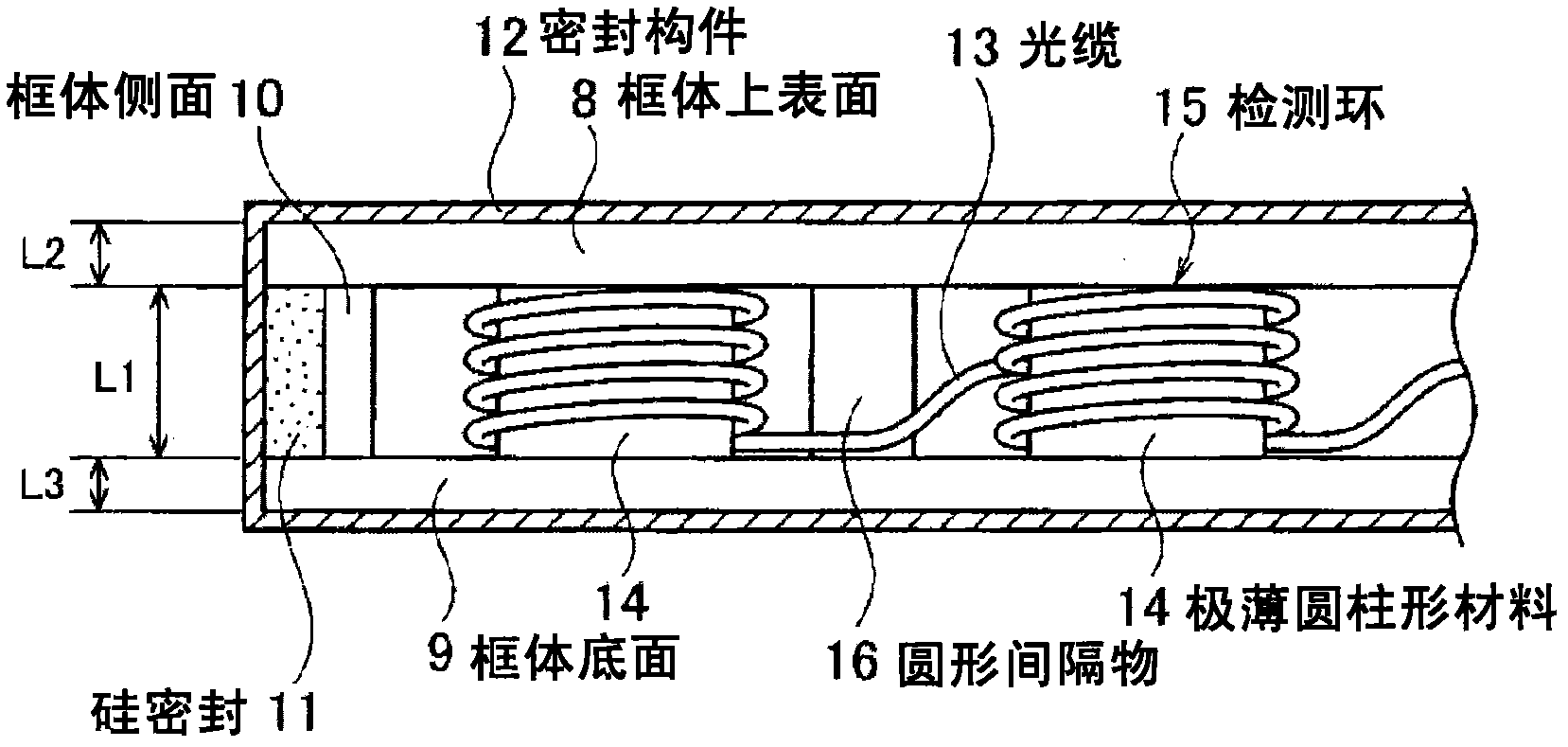

[0052] figure 1 It is a perspective view showing an edge heater provided with an optical fiber temperature sensor according to Embodiment 1 of the present invention. exist figure 1 Among them, on the lower surface of the rough plate strip 1 formed by the plate material, the heating coil 2 and the heat-resistant plate 3 are arranged oppositely, and between the heating coil 2 and the heat-resistant plate 3, an elliptical side heating plate is arranged. The fiber optic temperature sensor 4 is used for the device.

[0053] Such as figure 2 As shown, on the edge heater optical fiber temperature sensor 4, a frame body hole 80 is formed, and a figure 1The elliptical radial core 6 is shown. The heating coil 2 , the heat-resistant plate 3 , and the optical fiber temperature sensor 4 are arranged below the recess of the C-shaped core 5 . In addition, heating coil 2 , heat-resistant plate 3 (not shown), and optical fiber temperature sensor 4 (not shown) are also arranged above the ...

Embodiment 2

[0068] Figure 5 (a) is a perspective view showing a strip heater provided with an optical fiber temperature sensor according to Example 2 of the present invention. Figure 5 (b) is a cross-sectional view showing an optical fiber temperature sensor according to Example 2 of the present invention.

[0069] exist Figure 5 In the shown example 2, four flat-shaped optical fiber temperature sensors 4a to 4d are sequentially arranged on the inner lower surface side of the box-shaped heating coil 2a along the longitudinal direction of the heating coil 2a. On the upper surfaces of the optical fiber temperature sensors 4a to 4d, a heat-resistant plate 3a covering the rough strip 1 is arranged.

[0070] The shape of the optical fiber temperature sensors 4 a to 4 d for strip heaters is preferably flat. The reason is that the strip heater is formed by a wound heating coil 2a, and its surface opposite to the rough strip 1 is in a planar shape, and the strip heater optical fiber tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com