System and method for automatically judging subvolume surface quality grade

A surface quality and judgment system technology, applied in the field of grade system, can solve problems such as the inability to judge the surface quality grade of sub-rolls, and achieve the effect of fast detection speed and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

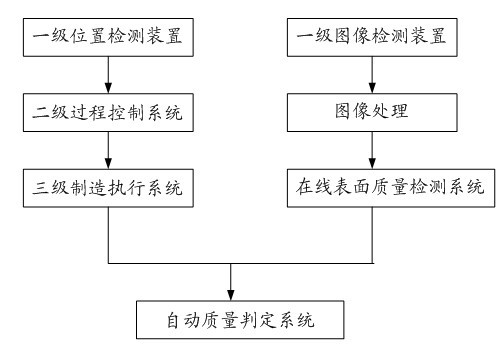

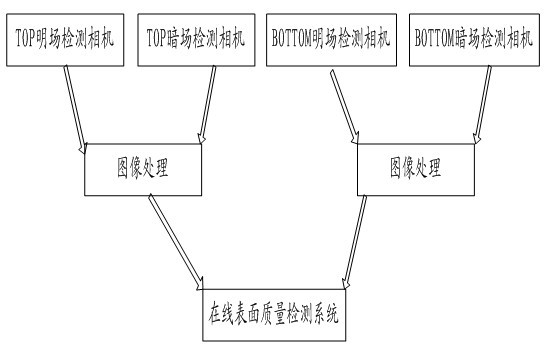

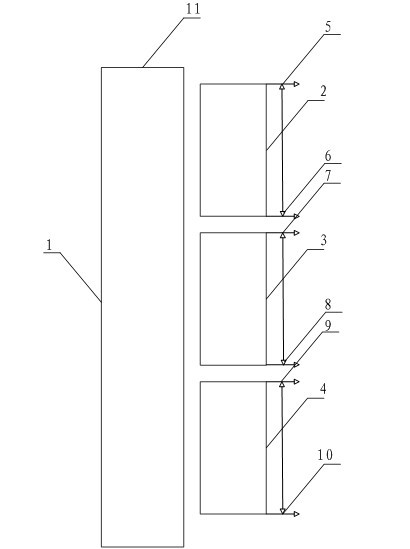

[0022] see figure 1 , a step diagram for automatically determining the surface quality level of a sub-roll provided by an embodiment of the present invention, a system for automatically determining the surface quality level of a sub-roll, and the specific equipment is shown in Table 1. Including, grating, secondary process control system, tertiary manufacturing execution system, camera, online surface quality inspection system and automatic quality judgment system, among which, grating is connected with secondary process control system through data interface, and secondary process control system is connected with tertiary process control system The first-level manufacturing execution system is connected through the data interface, the camera is connected with the online surface quality inspection system through the data interface, and the automatic quality judgment system is respectively connected with the third-level manufacturing execution system and the online surface qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com