Thin film transistor array substrate and manufacturing method thereof

A technology of thin film transistors and array substrates, applied in the field of thin film transistor array substrates and its production, can solve the problems of low yield rate, high product cost, and excessive mask exposure times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

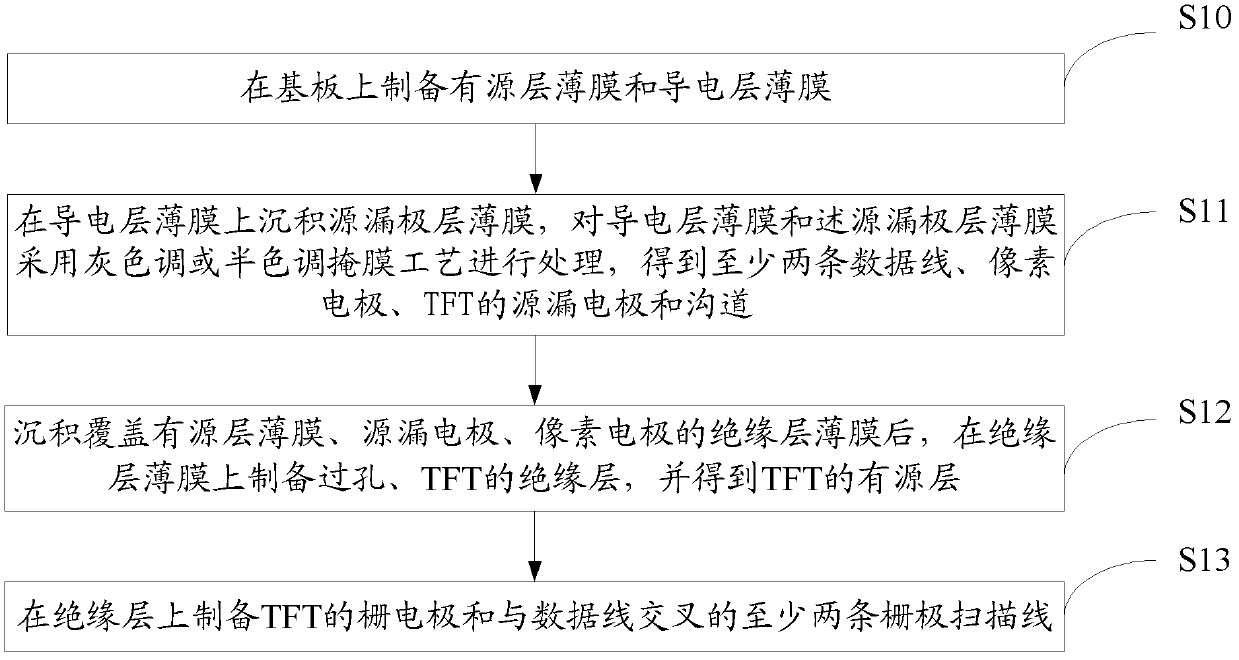

[0028] Aiming at the problems of high product cost, low yield rate and low equipment capacity caused by too many mask exposure times in the process of manufacturing a thin film transistor array substrate in the prior art, an embodiment of the present invention provides a method for manufacturing a thin film transistor array substrate method, the flow of the method is as follows figure 1 As shown, the specific execution steps are as follows:

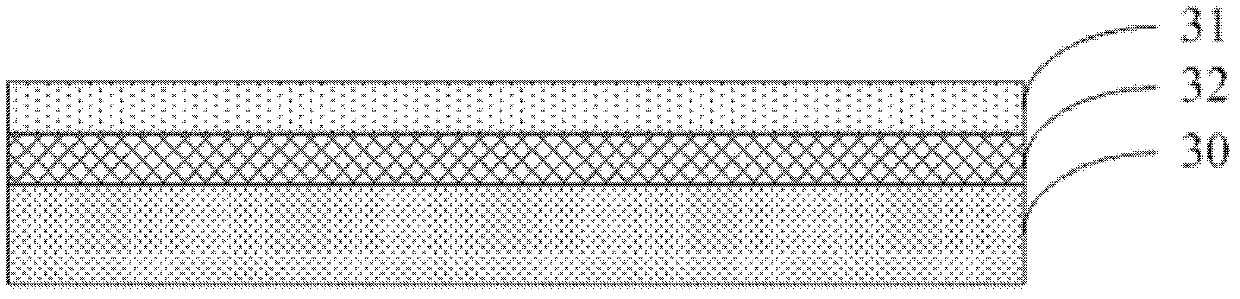

[0029] S10: preparing an active layer thin film and a conductive layer thin film on the substrate.

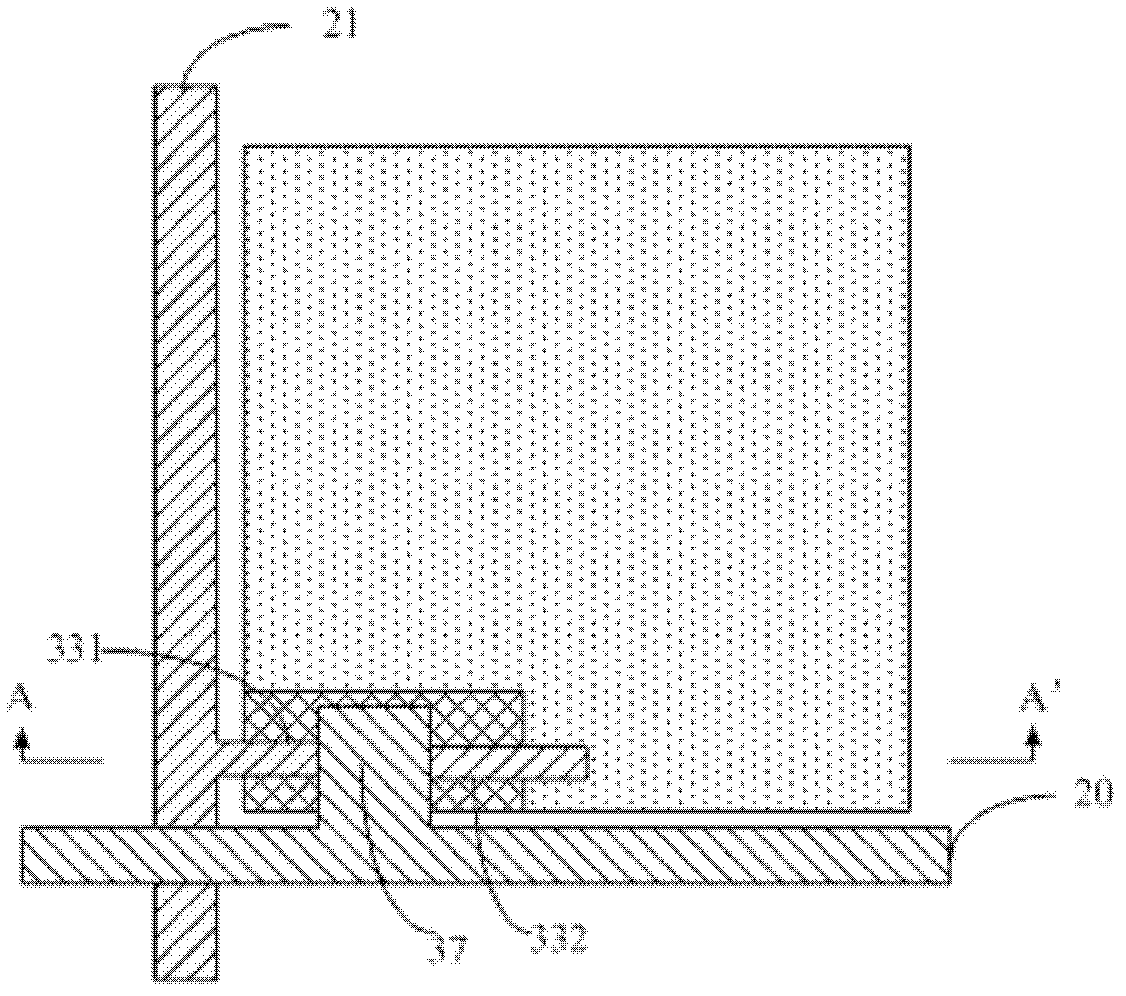

[0030] S11: Deposit the source-drain layer film on the conductive layer film, and process the conductive layer film and the source-drain layer film with a gray-tone or half-tone masking process to obtain at least two data lines, pixel electrodes, and TFT sources The drain electrode and the channel; the source of a row of TFTs on the array substrate is connected to a data line.

[0031] S12: After depositing the insulating layer film cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com