Fertilizer applicator for crop seedlings

A fertilizer applicator and seedling technology, which is applied in the field of crop seedling fertilizers, can solve the problems of low work efficiency, inability to apply deep into the soil layer, and high production cost, and achieve continuous adjustment of row spacing, easy access to a wide range of supporting power, and accurate control Effect of Fertilizer Amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

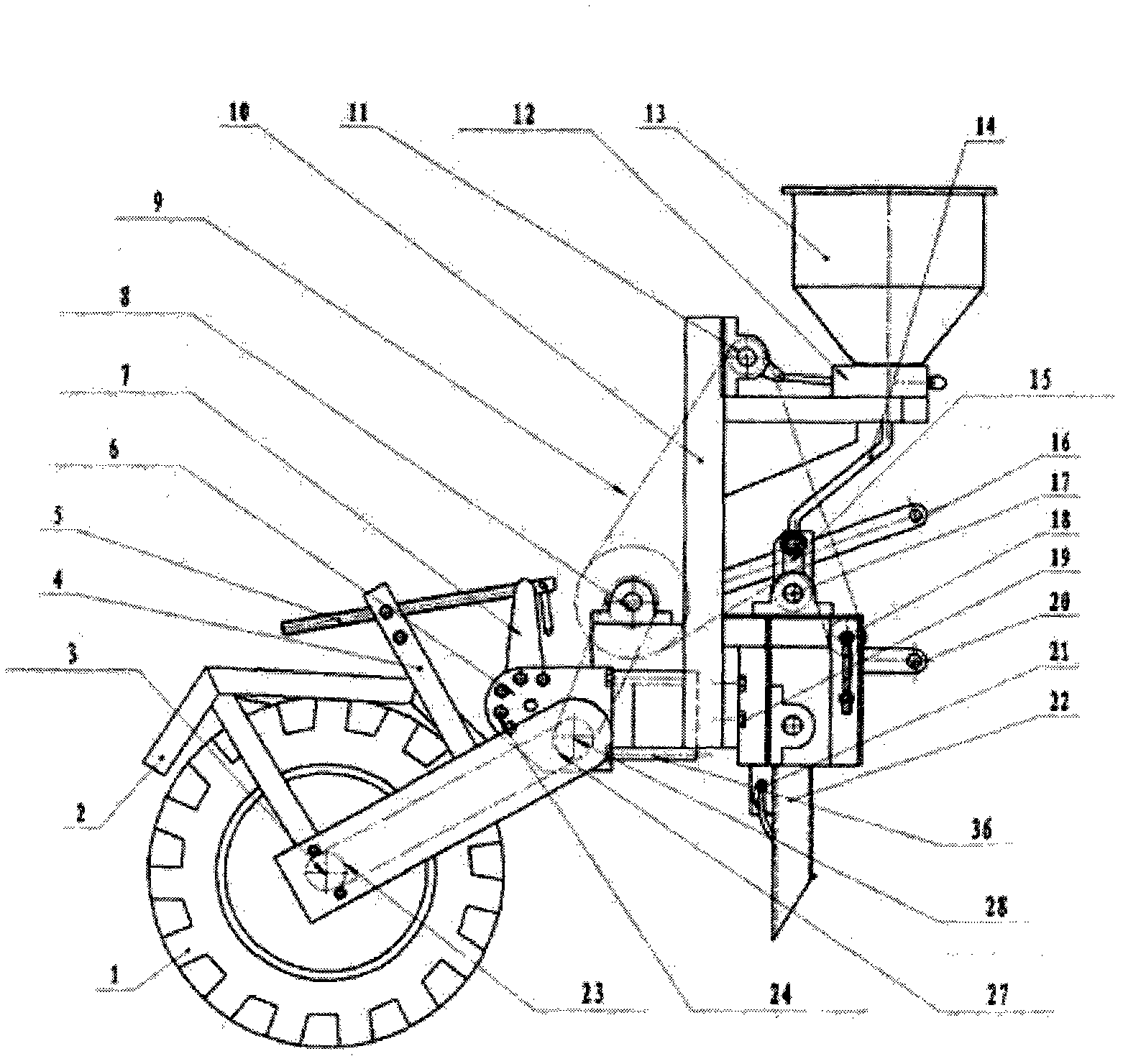

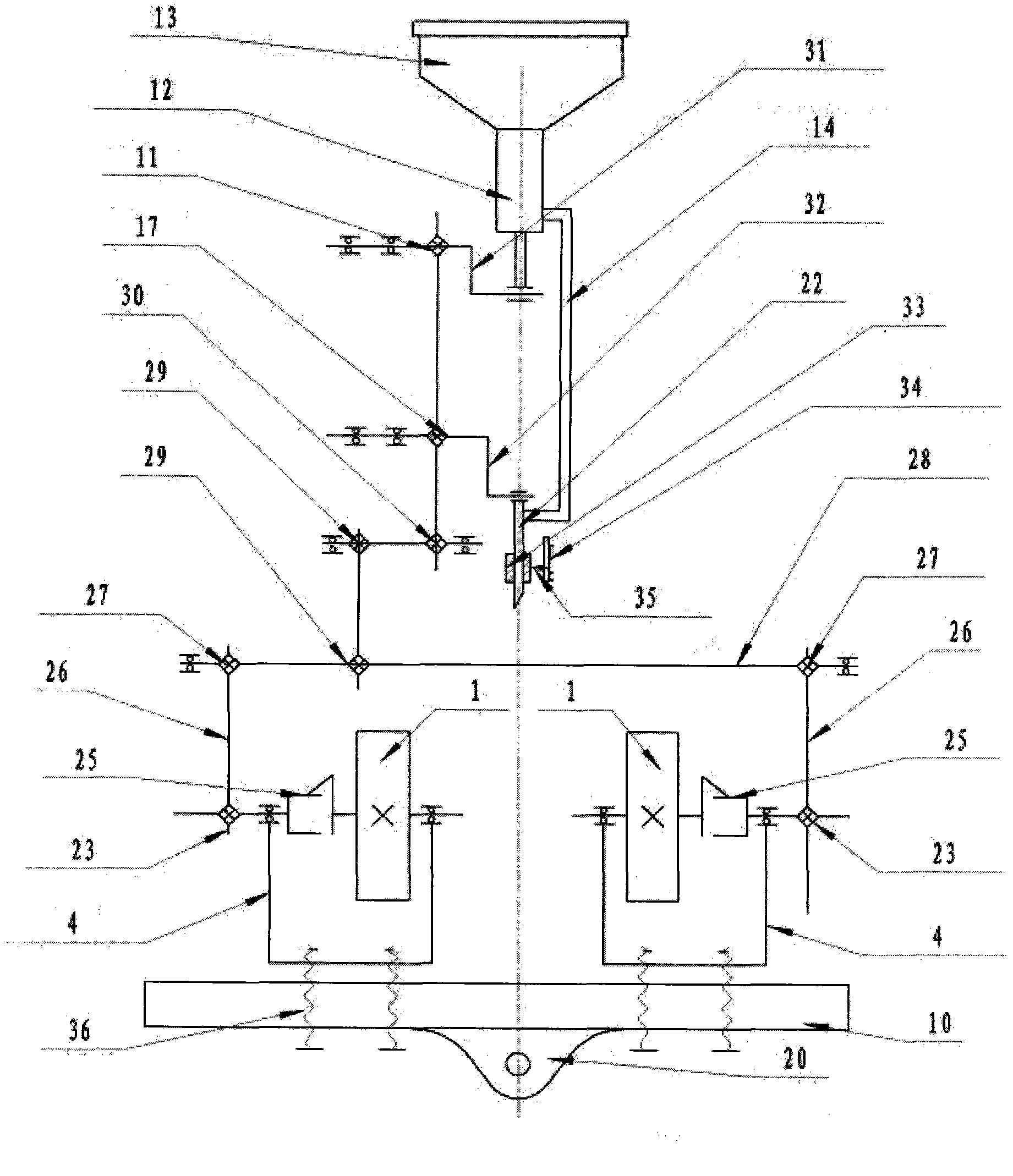

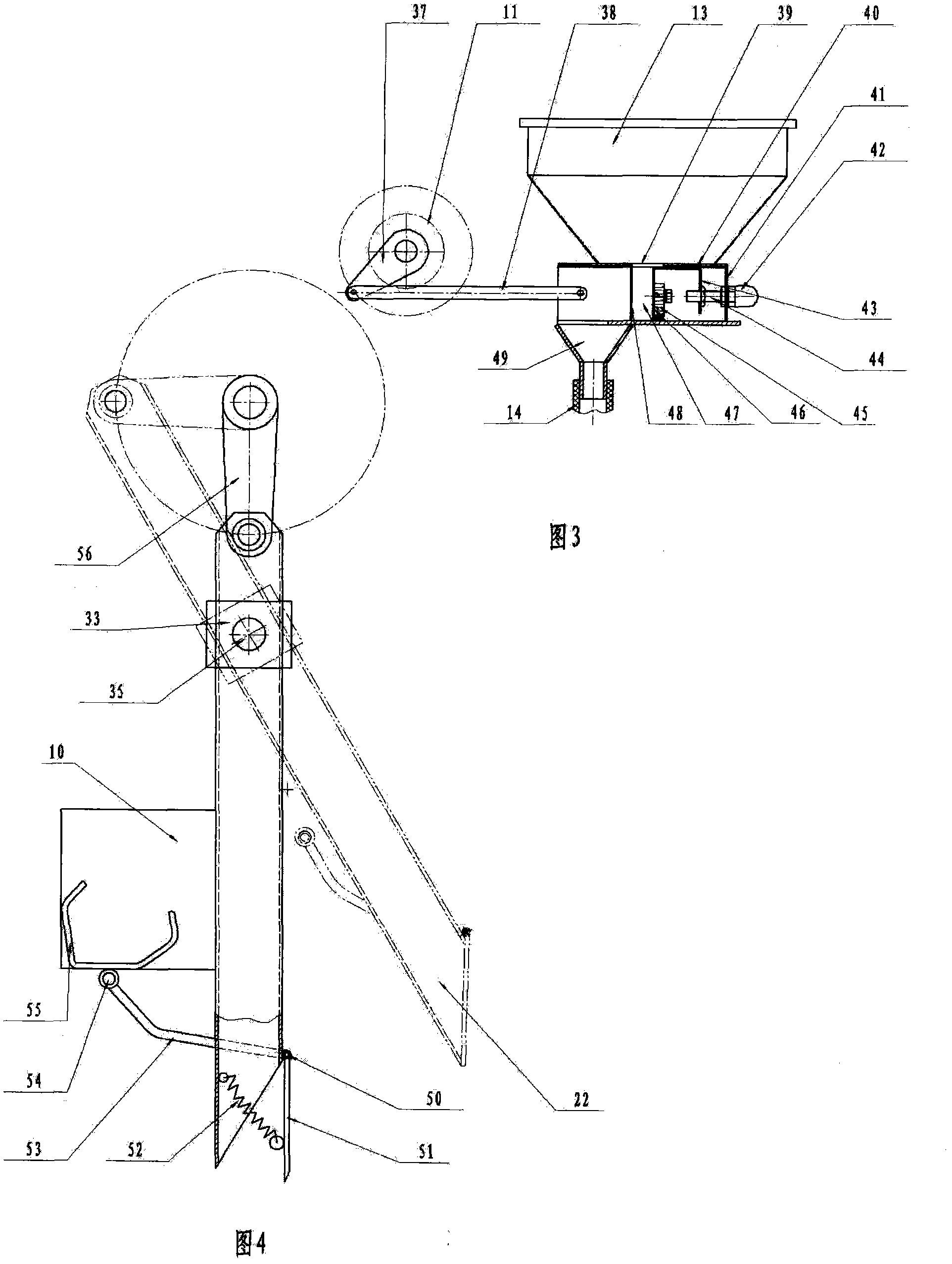

[0036] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4As shown, only one fertilizer applicator assembly is installed on the frame 10, the tractor is connected with the traction frame 20 and the lifting frame 16, the fertilizer applicator is dragged forward, the driving wheel 1 rotates, and the driving chain is driven by the ratchet mechanism 25 on the driving wheel Wheel 25 rotates, drives driven sprocket 27 to rotate by chain 26, and driven sprocket 27 drives long keyway drive bar 28 to rotate, and sprocket wheel 29 drives variable-speed sprocket 30 to rotate, and variable-speed sprocket 30 drives quantitative lower fertilizer chain simultaneously by chain Wheel 11, fixed-point fertilization sprocket wheel 17 and tension wheel 18 rotate. The lower fertilizer sprocket 11 drives the lower fertilizer crank 37 to rotate, and the lower fertilizer connecting rod 38 drags the sliding material box 41 to move back and forth, and the lower fertilizer mouth of the fertil...

Embodiment 2

[0040] Embodiment 2: as figure 1 , figure 2 , image 3 , Figure 4 As shown, 10 fertilizer applicator assemblies are installed on the frame 10, the tractor is connected with the traction frame 20 and the lifting frame 16, the fertilizer applicator is dragged forward, the driving wheel 1 rotates, and the driving chain is driven by the ratchet mechanism 25 on the driving wheel Wheel 25 rotates, drives driven sprocket 27 to rotate by chain 26, and driven sprocket 27 drives long keyway drive bar 28 to rotate, and sprocket wheel 29 drives variable-speed sprocket 30 to rotate, and variable-speed sprocket 30 drives quantitative lower fertilizer chain simultaneously by chain Wheel 11, fixed-point fertilization sprocket wheel 17 and tension wheel 18 rotate. The lower fertilizer sprocket 11 drives the lower fertilizer crank 37 to rotate, and the lower fertilizer connecting rod 38 drags the sliding material box 41 to move back and forth, and the lower fertilizer mouth of the fertiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com