Numerical control tea flatting mill

A technology of tea flattening machine and numerical control system, which is applied in the direction of tea processing before extraction, can solve the problems of high labor intensity, low work efficiency, and difficult quality assurance, and achieve the effect of low labor intensity, high work efficiency and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

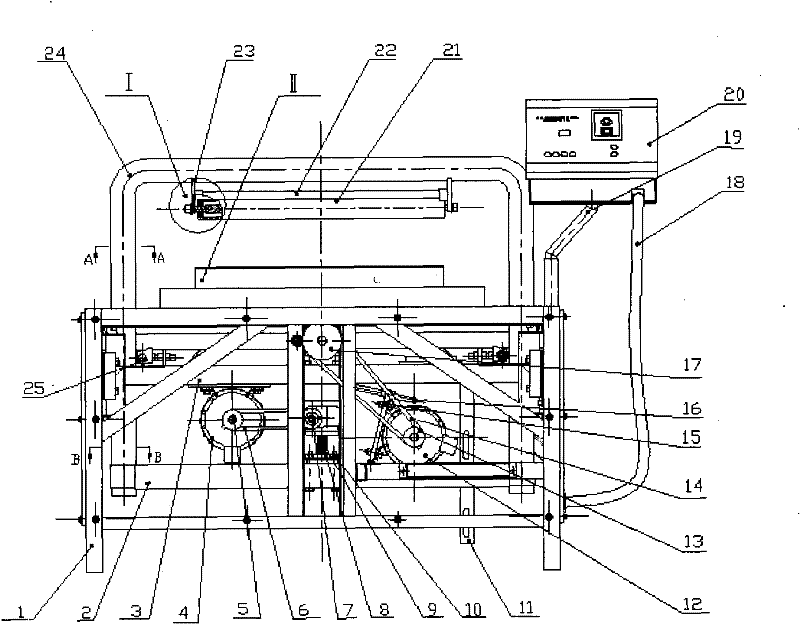

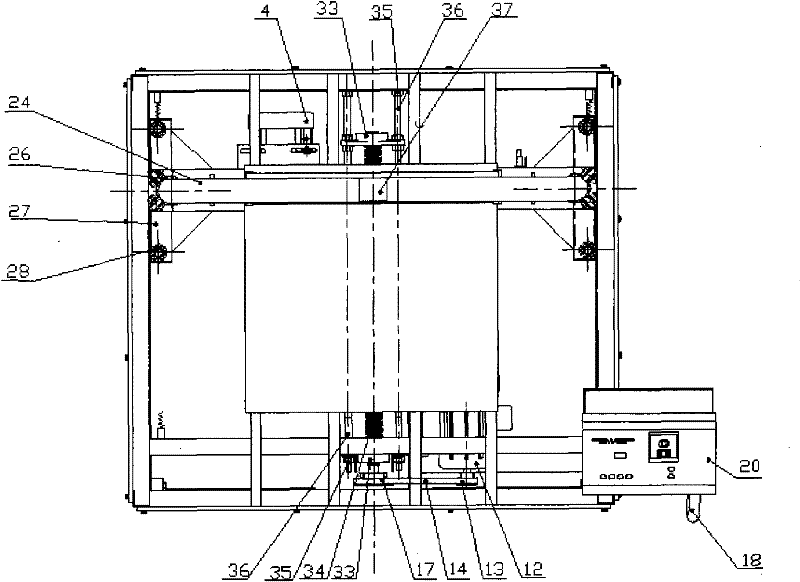

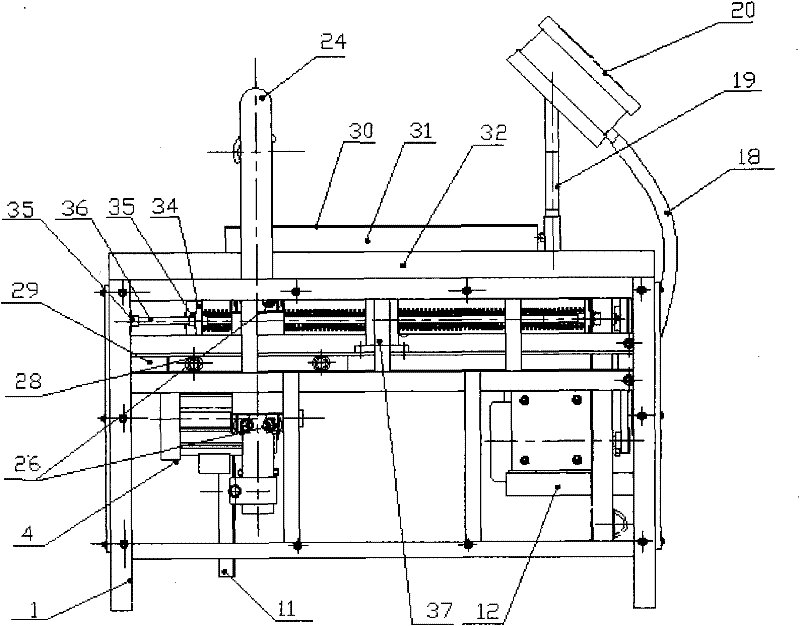

[0035] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Shown in the embodiment of a kind of numerical control tea flattening machine of the present invention.

[0036] The up and down motion of cylinder 21 is realized like this:

[0037] The lifting motor 4 drives the worm wheel 7 to rotate through its pulley 5 and the V-belt 6 to drive the worm 9 to rotate, and the worm 9 rotates to drive the lifting nut 8 to move up and down. Frame 2 and lifting nut 9 move up and down together.

[0038] The lower frame 2 clamps the roller frame 24 by clamps 38 and bolts, nuts, and gaskets 39, so that the roller frame 24 and the lower frame 2 move up and down together.

[0039] There are two guide wheels 26 on the outside of the roller frame 24 for guidance, and one adjustment wheel 25 on the inside. The guide wheels 26 and the adjustment wheels 25 play a role in positioning and guiding the roller frame 24. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com