Dispensing process for LED (light-emitting diode) encapsulation

A technology for LED packaging and dispensing, which can be applied to devices, electrical components, circuits, etc. that apply liquid to the surface, and can solve problems such as increased cost, misalignment, and reduced packaging yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

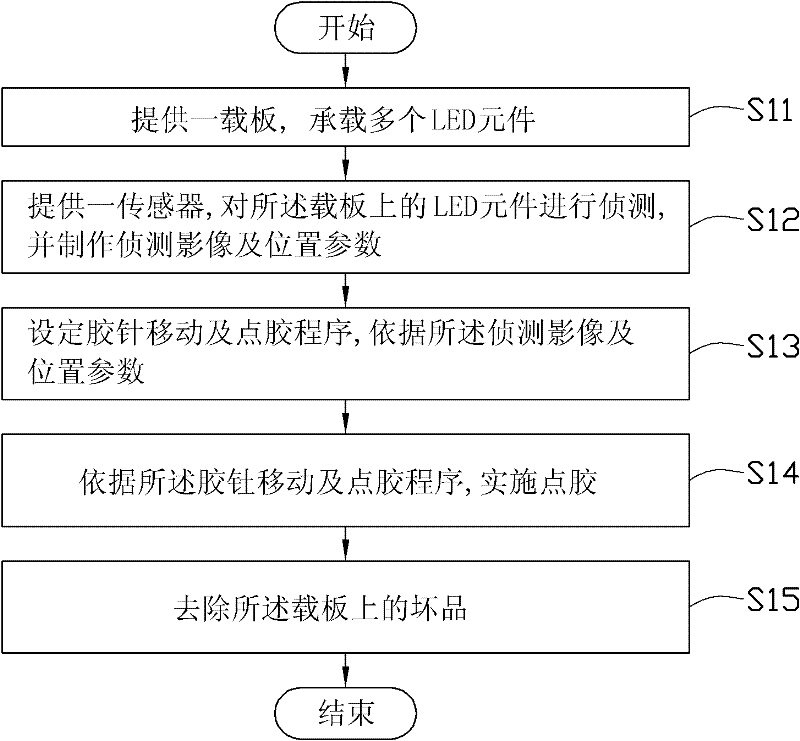

[0027] see figure 1 , is shown as a flow chart of the steps of the dispensing process of the LED package of the present invention, which includes the following steps:

[0028] S11 provides a carrier board to carry multiple LED components;

[0029] S12 provides a sensor to detect the LED elements on the carrier board, and make detection images and position parameters;

[0030] S13 sets the movement of the glue needle and the glue dispensing program, according to the detection image and position parameters;

[0031] S14 implement dispensing according to the movement of the glue needle and the dispensing procedure; and

[0032] S15 removing defective products on the carrier.

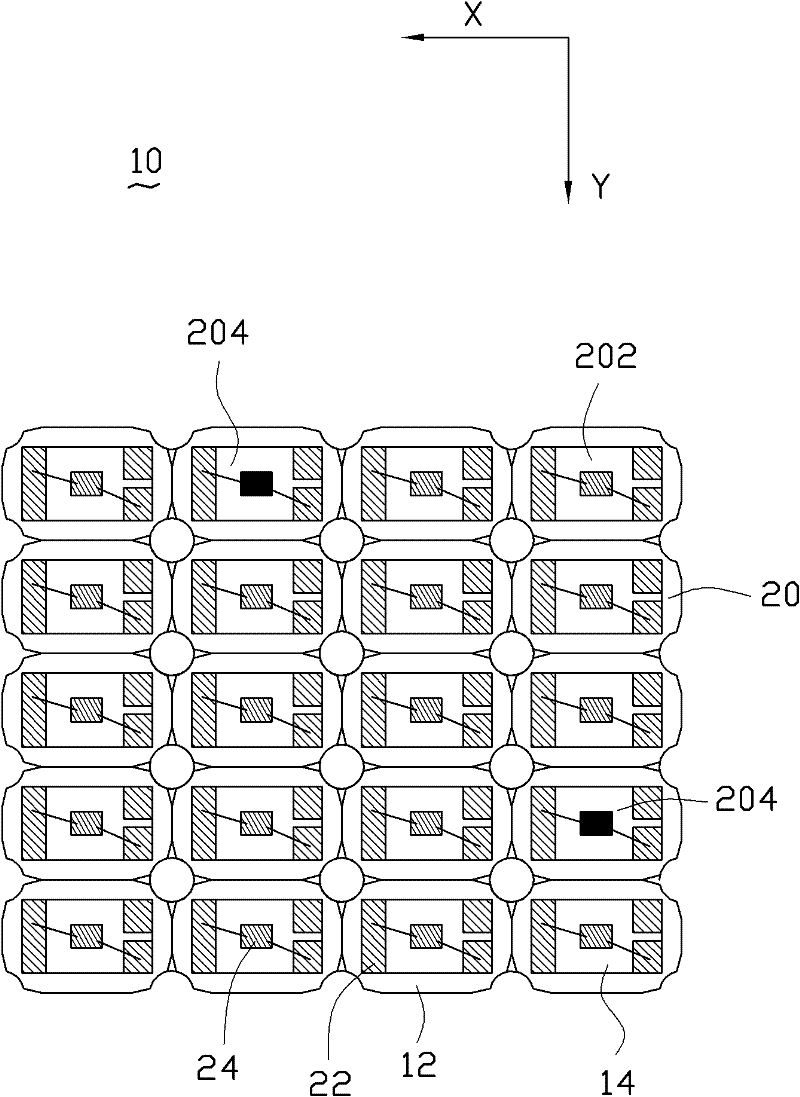

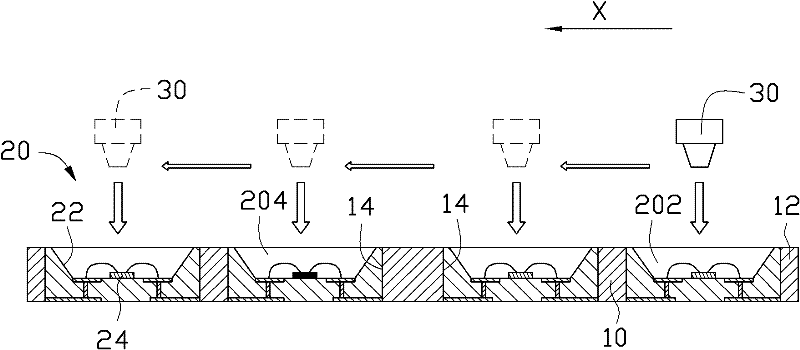

[0033] The step S11 provides a carrier board to carry a plurality of LED elements; the carrier board 10 includes a lead frame type, a ceramic chip compact type or a light bar type (Light bar),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com