Performance prediction model based dynamic control method for mechanical property of hot strip

A technology for hot-rolled strip steel and forecasting model, which is applied to rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of complex calculation process, quality requirements of model input data, etc., so as to improve control accuracy and realize dynamic control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

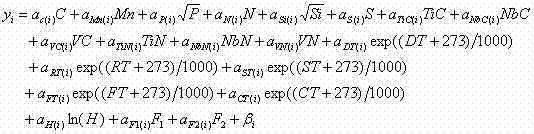

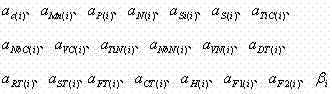

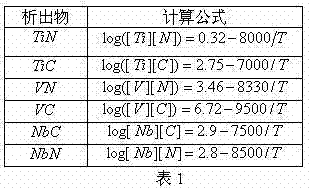

Method used

Image

Examples

Embodiment 1

[0014] A dynamic control method for the mechanical properties of hot-rolled strip steel based on a performance prediction model. Before the strip steel is rolled, the chemical composition, preset rolling process parameters, and specification parameters are firstly retrieved, and then according to the preset rolling The pre-set coiling temperature in the process parameters calculates the content of precipitated alloy compounds, and then brings all the data into the mechanical property prediction model of hot-rolled strip steel, and uses the model to predict the mechanical properties of strip steel after rolling. The rolling process parameters are used to make the predicted value of the mechanical properties of the strip meet the constraints of the target value of the mechanical properties, and then rolling is carried out according to the adjusted rolling process parameters.

[0015] It should be noted that when the present invention is used for control, there may be a small devi...

Embodiment 2

[0083] The difference between embodiment 2 and embodiment 1 is that, according to the actual results of continuous casting composition detection, the chemical composition of a certain steel strip is as follows:

[0084] : 0.16630, : 0.077, : 0.35, : 0.17, : 0.0098, : 0.0032

[0085] The preset value of process parameter is:

[0086] : 1240°C, : 1040°C, : 990°C, : 850℃, : 650°C

[0087] Thickness specification is 6mm, rough rolling reduction rate : 17.2%, finishing rolling reduction : 15.7%.

[0088]

[0089] 1) Input the collected chemical composition and rolling parameters into the mechanical performance prediction model, and the calculation result is:

[0090] tensile strength Mpa, yield strength MPa

[0091] 2) Compare the predicted values of tensile strength and yield strength with the required mechanical properties, where the thresholds of tensile strength and yield strength are selected as 4Mpa and 5Mpa, respectively.

[0092]

...

Embodiment 3

[0103] The difference between embodiment 3 and embodiment 1 is that, according to the chemical composition detection result of continuous casting molten steel, the composition content of certain strip steel is as follows:

[0104] : 0.0822, : 0.26, : 0.9, : 0.013, : 0.0065, : 0.0032

[0105] The preset value of process parameter is:

[0106] : 1210℃, : 981°C, : 961°C, : 800℃, : 530°C

[0107] Thickness specification is 2.4mm, rough rolling reduction : 11.1%, finishing rolling reduction : 9.7%.

[0108]

[0109] 1) Input the collected chemical composition and rolling process parameters into the mechanical performance prediction model, and the calculation result is:

[0110] Tensile strengthys 1 = 575 Mpa, yield strength ys 2 = 416 MPa

[0111] 2) Compare the predicted values of tensile strength and yield strength with the required mechanical properties, where the thresholds of tensile strength and yield strength are selected as 3Mpa and 4Mp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com