Efficient pretreatment system for mine water

A mine water and pretreatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Problems such as plate sedimentation tank collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

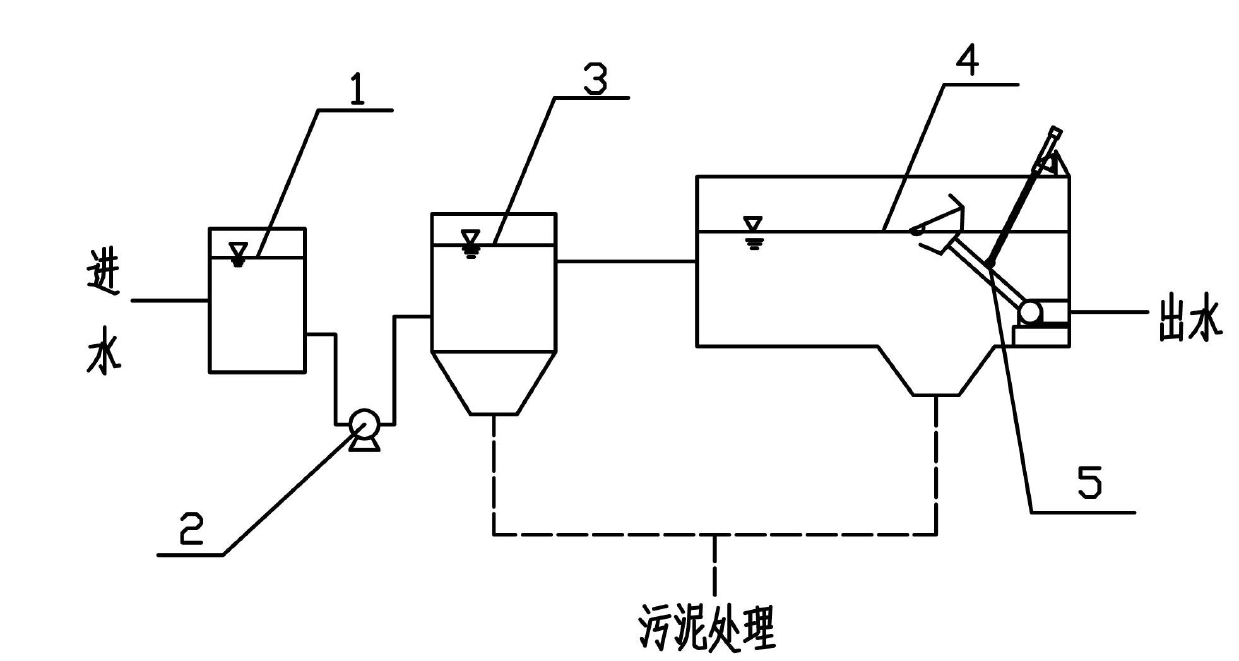

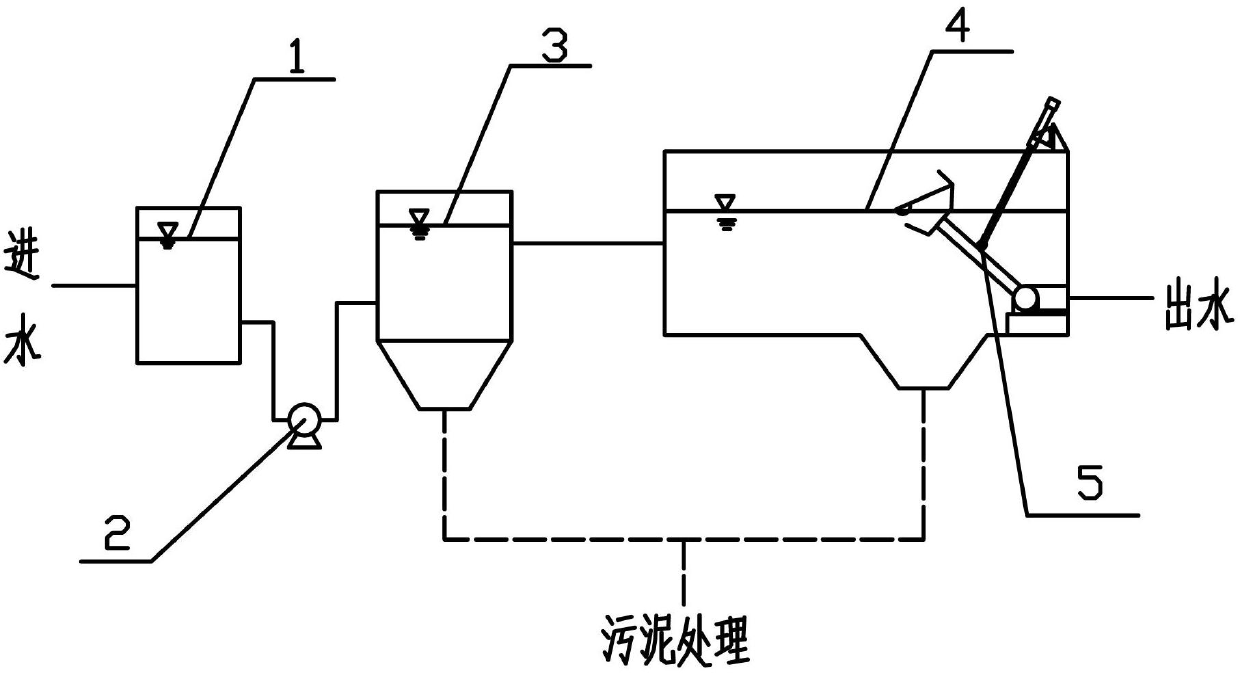

[0027] Such as figure 1 As shown, the system includes a sump 1, a lift pump 2, a sludge thickening tank 3, an advection sedimentation tank 4, a decanter 5 installed at the end of the advection sedimentation tank and an automatic control system (not shown in the figure).

[0028] Raw mine water is lifted from the underground to the collection pool 1, and after being lifted by the lift pump 2, it enters the sludge thickening tank 3 for concentration pretreatment, and then enters the advection sedimentation tank 4 for further treatment, and the decanting device 5 at the end of the advection sedimentation tank 4 Skim off the supernatant water in the pool to realize the separation of supernatant water and suspended matter. The whole operation process is controlled by the automatic control part of the system according to the liquid level change in the regulating tank.

[0029] The sludge thickening tank 3 adopts a radial flow sludge thickening tank, which pretreats the raw water by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com