Suspension piston type cylinder component

A piston type and cylinder technology, applied in the direction of cylinders, cylinder heads, engine components, etc., can solve the problems of wear resistance degradation, inner wall wear of cylinders, etc., and achieve the effect of preventing direct contact friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

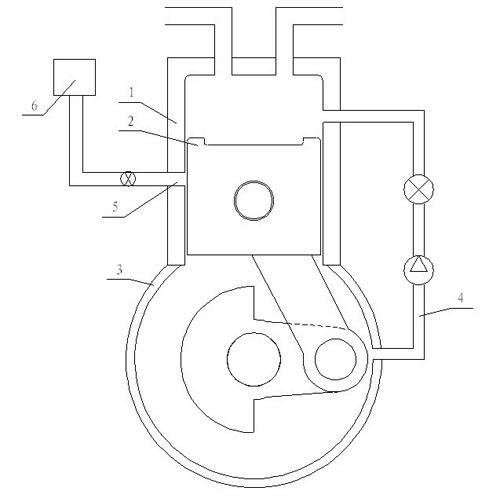

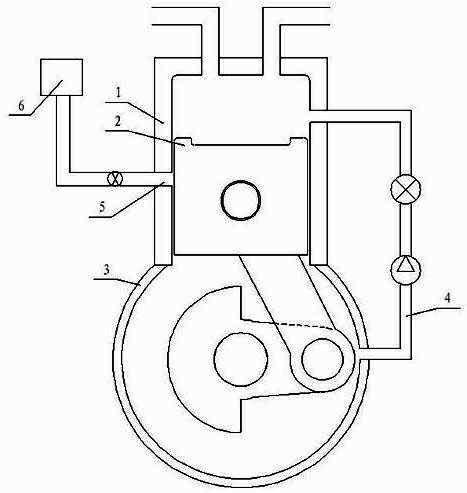

[0009] Such as figure 1 As shown, the suspended piston cylinder assembly described in the embodiment of the present invention includes a cylinder 1, a piston 2 and a closed crankcase 3, the crankcase 3 is docked with the cylinder 1 and sealed, and the piston 2 is connected to the inner wall of the cylinder 1 There is a clearance fit between the cylinder 1 and the piston 2 for sliding sealing without a sealing ring. A gas backfilling pipeline 4 is connected to the side wall of the crankcase 3, and the gas backfilling pipeline 4 is connected to the cylinder 1 correspondingly. The position below the top dead center of the piston; a cooling fluid inlet 5 is provided on the side wall of the cylinder 1, and the cooling fluid inlet 5 communicates with a high-pressure cooling fluid container 6 and is provided with a control valve on the passage, and the cooling fluid inlet 5 is located on the side wall of the cylinder corresponding to the area between the top dead center and the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com