Rotational speed and torque control device and method of wind turbine generator set

A technology of wind power generating set, rotational speed and torque, which is applied in the control of wind power generator, wind power generator, wind power generation, etc. It can solve problems such as wind rotor rising, overspeed and overload, and lower quality of power generation, so as to reduce dynamic load and reduce power consumption. The effect of small speed fluctuation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

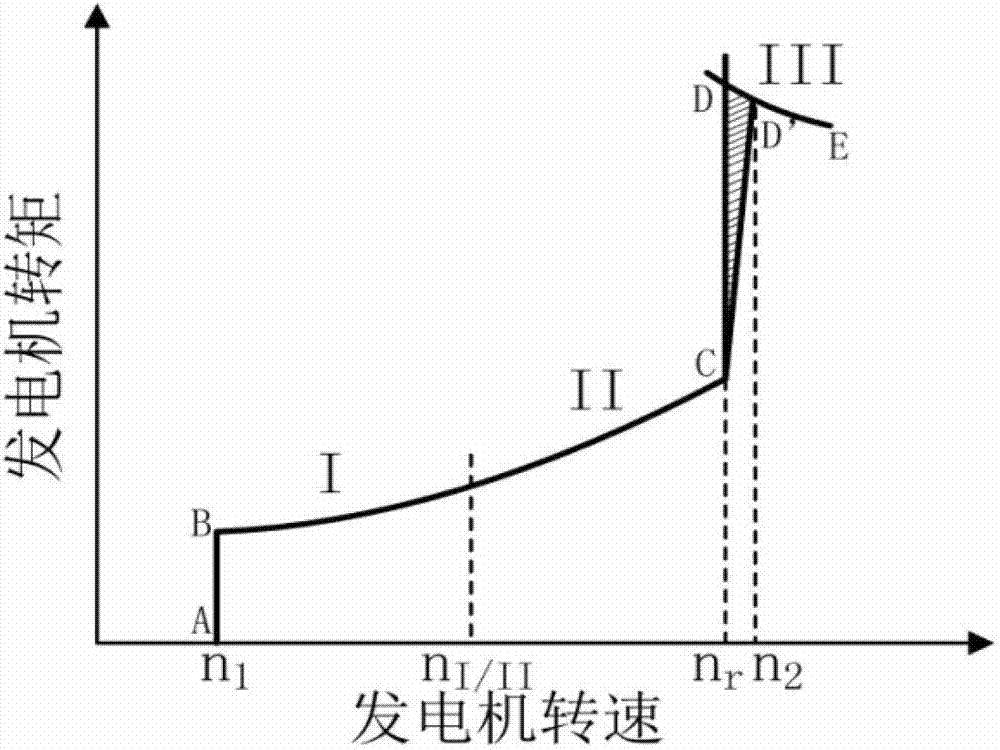

[0072] The wind conditions used in the simulation are: the average wind speed is 11.7m / s, and the turbulence intensity is 9.45%. The simulation results are as follows Figure 6-9 , the thick line in the figure represents the result of the control method of the present invention, and the thin line represents the result of other existing control methods. Figure 6 is the wind speed, Figure 7 is the rotor speed, Figure 8 is the pitch angle, Figure 9 for power. It can be seen from the result figure that when the wind speed fluctuates near the rated wind speed and the wind speed suddenly rises below the rated operating point using the control method of the present invention, the coordinated control of torque and pitch can better realize the flexible conversion of the control area, which is different from that of Compared with other existing control methods, the fluctuation of speed and power is greatly reduced, the stability of the unit under various wind conditions is improv...

Embodiment 2

[0074] The wind conditions used in the simulation are: the average wind speed is 14m / s, and the turbulence intensity is 10.01%. The simulation results are as follows Figure 10-13 , the thick line in the figure represents the result of the control method of the present invention, and the thin line represents the result of other existing control methods. It can be seen from the result graph that the constant power control method of the present invention can effectively realize the stability of power output when the area above the rated wind speed is adopted. The non-linear pitch control parameter adjustment method realizes the nonlinear change trend control of the pitch action, enhances the followability of the pitch action with the change of wind speed, and ensures the stable operation of the fan speed. Compared with other existing control methods, it can significantly improve the stability of power output and speed, and can effectively reduce the limit and fatigue load of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com