Embedded control system applied to LNG (liquefied natural gas) dispensers

An embedded control and embedded technology, applied in general control systems, control/regulation systems, computer control, etc., can solve the problem that the power supply is easy to interfere and affect each other, affect the normal operation of other modules, and the use is not reasonable and user-friendly, etc. problems, to achieve the effect of facilitating remote data transmission or remote maintenance, rational use and humanization, and improving data exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

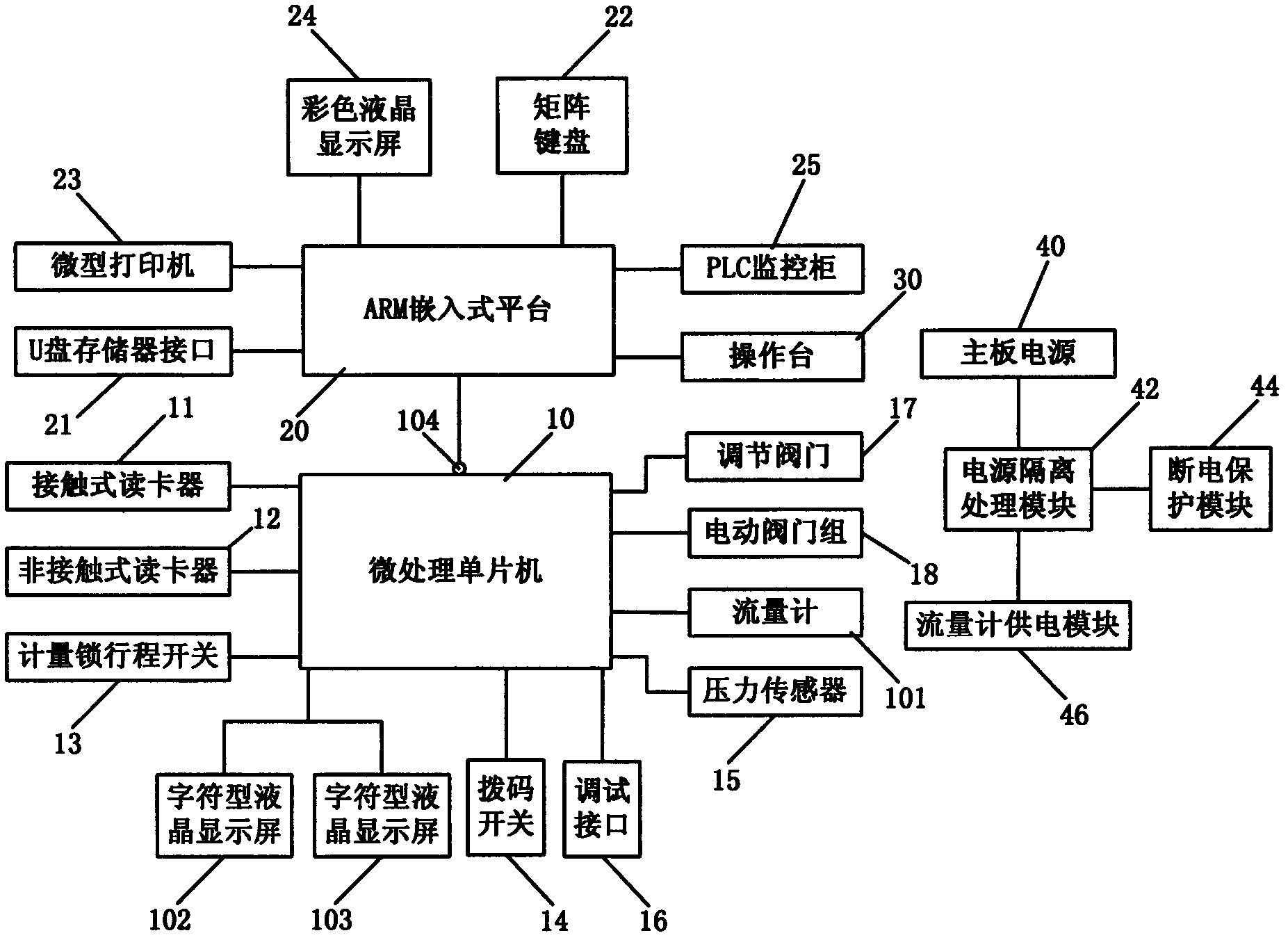

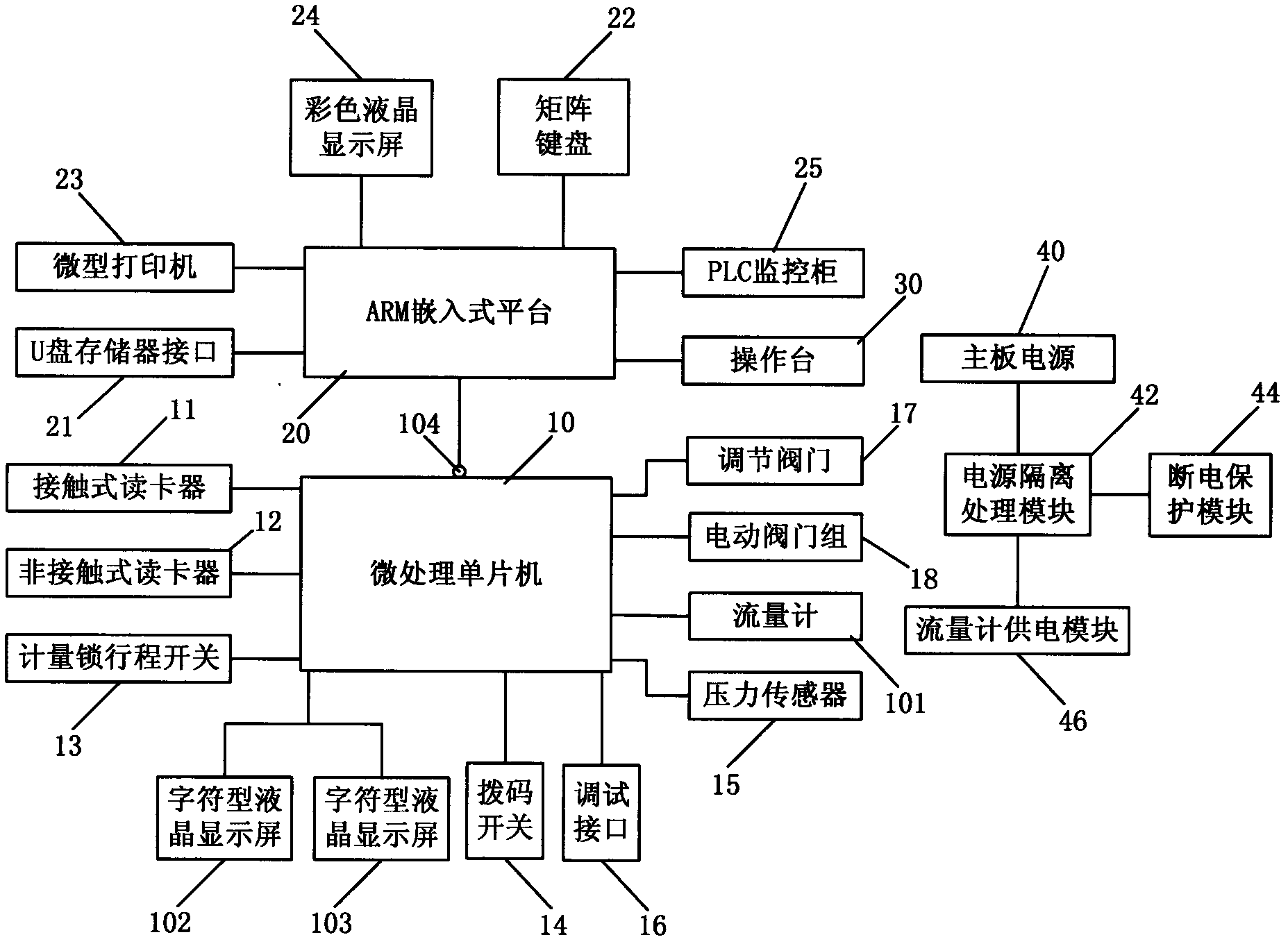

[0016] Such as figure 1 As shown, the present invention provides an embedded control system applied to an LNG filling machine, which includes a micro-processing single-chip microcomputer 10, and also includes a microprocessor (ARM: Advanced RISC Machines) embedded with the micro-processing single-chip microcomputer 10. Platform 20, console 30 communicating with ARM embedded platform 20TCP / IP, motherboard power supply 40, power isolation processing module 42 electrically connected with motherboard power supply 40, and power-off protection module electrically connected with power isolation processing module 42 44; the microprocessing single-chip microcomputer 10 is used for the acquisition, process control, and output display of the bottom layer data of the system, and submits relevant data to the ARM embedded platform 20; the ARM embedded platform 20 is connected with the microprocessing single-chip microcomputer 10 for communication, and The relevant data submitted by the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com