Laser three-differential cofocal theta imaging detection method

A differential confocal and imaging detection technology, applied in measuring devices, optical devices, instruments, etc., can solve the problem of limited measurement accuracy, light source intensity fluctuations, restrictions on confocal sensor focus tracking accuracy, poor confocal intensity response sensitivity, etc. problem, to achieve the effect of measuring range and resolving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

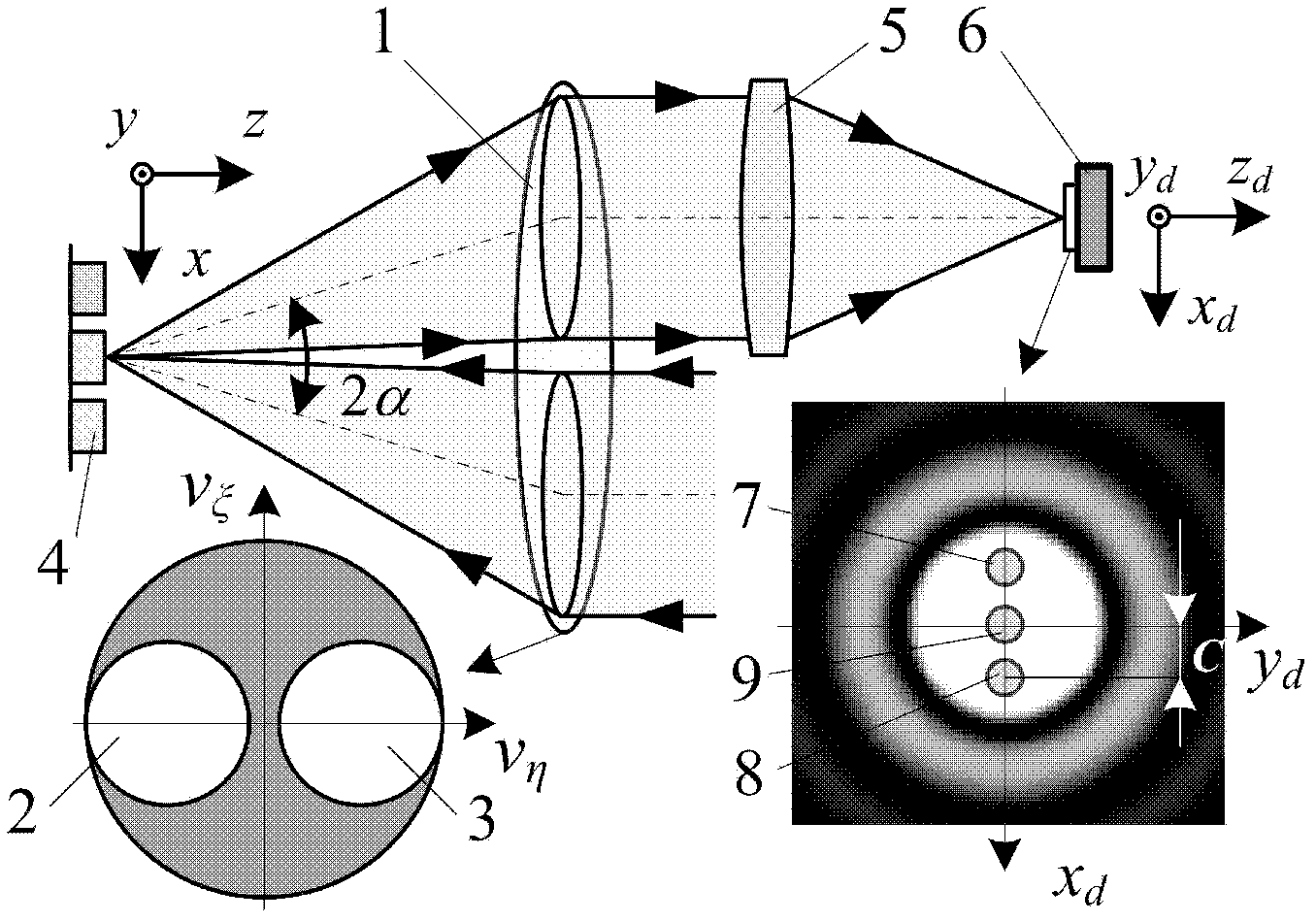

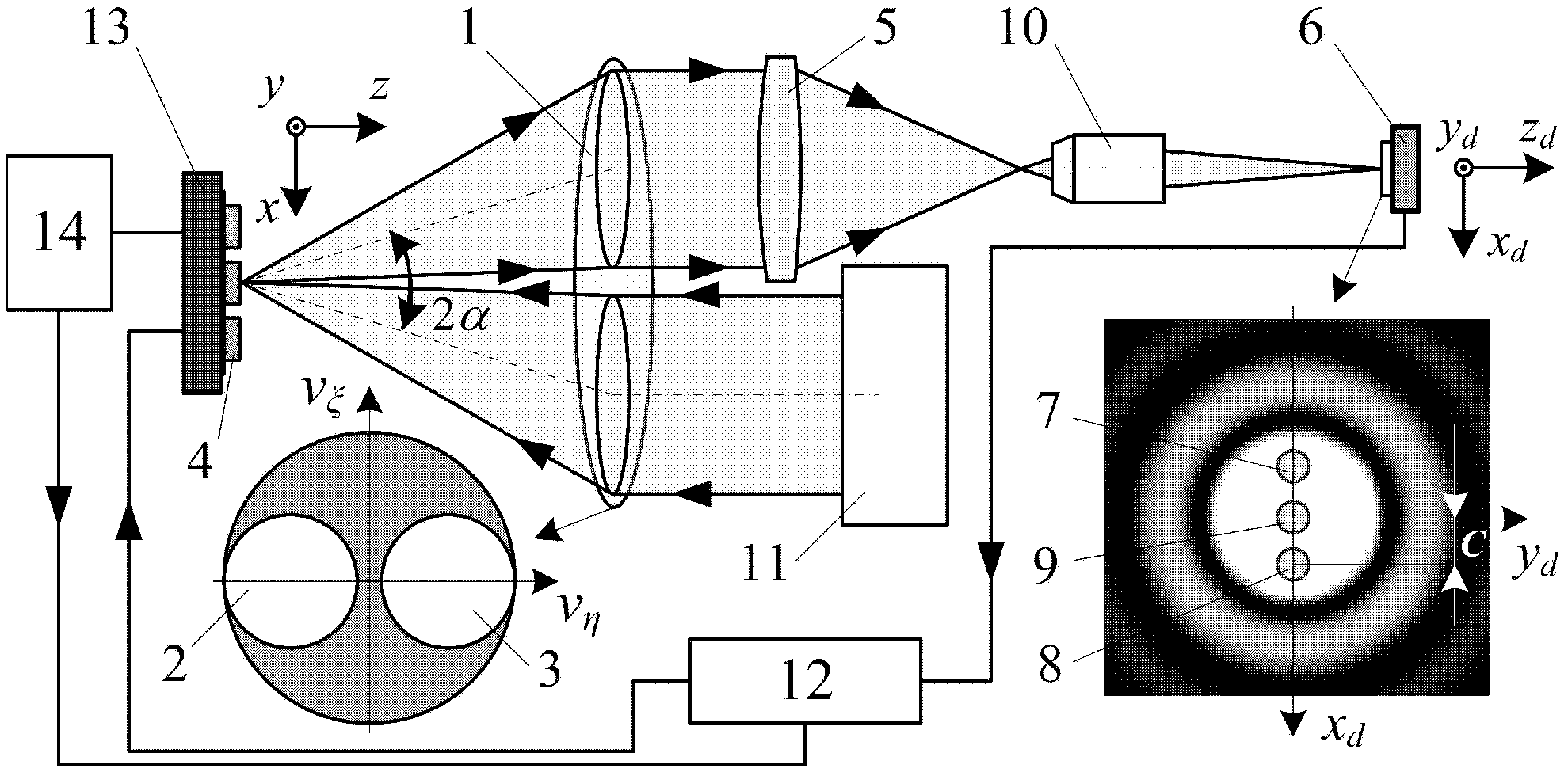

[0035] The embodiment structure of the present invention is as figure 2As shown, in order to facilitate the detection of the divided focal spot by the detector, in this embodiment, the image on the focal plane of the converging objective lens 5 is enlarged to the detection surface of the subsequent detector 6 through the magnifying objective lens 10 . The laser triple differential confocal theta imaging detection method of the present invention is further described as follows:

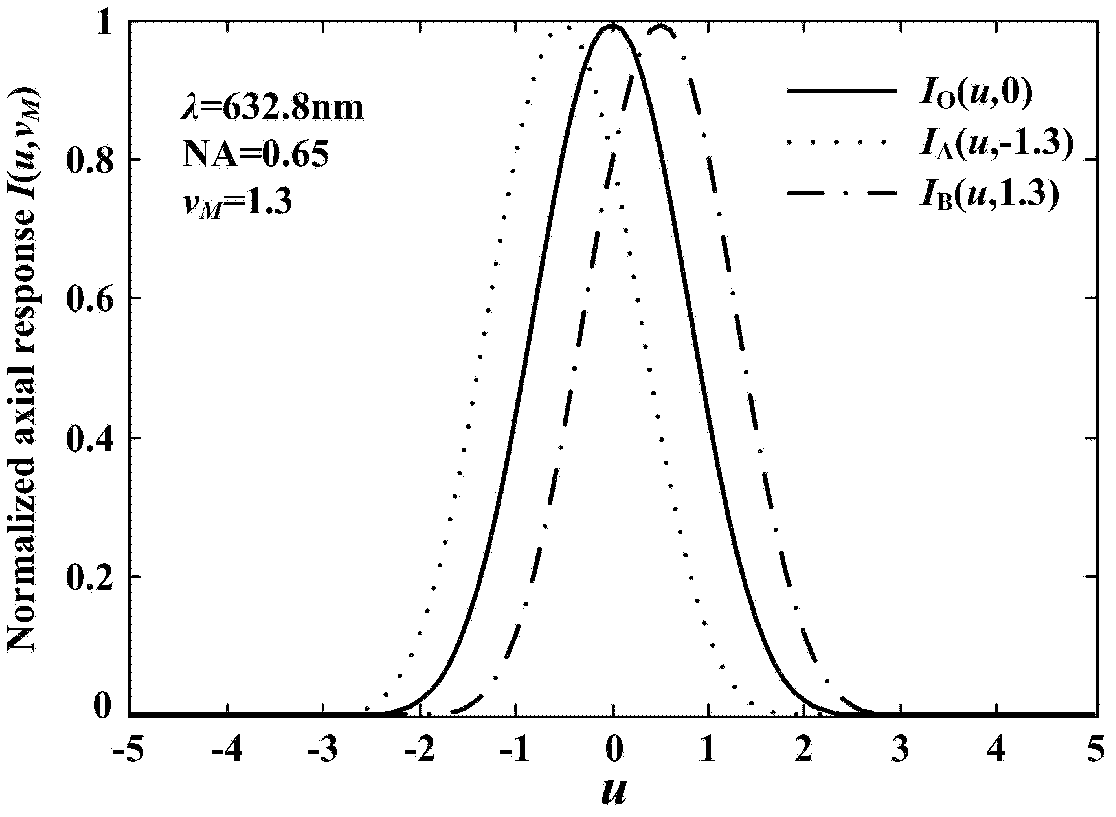

[0036] Such as figure 2 As shown, the parallel light beam emitted from the light source system 11 passes through the illumination pupil 2 and is converged by the objective lens 1 to the surface of the measured sample 4, and the reflected light carrying the information of the measured sample 4 passes through the collecting pupil 3 and is converged by the converging objective lens 5 On the detection surface of the detector 6, at the focal point in the detection surface, along the x d axis direction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com