Three-axis micro-mechanical gyroscope

A micro-machined gyroscope and gyroscope technology, applied in the field of micro-electromechanical systems, can solve the problems such as the inability to meet the requirements of miniaturization of gyroscopes, the development of three-axis gyroscopes, and the complexity of design and manufacture, and achieve good measurement accuracy and sensitivity. The effect of compact structure, reduced size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

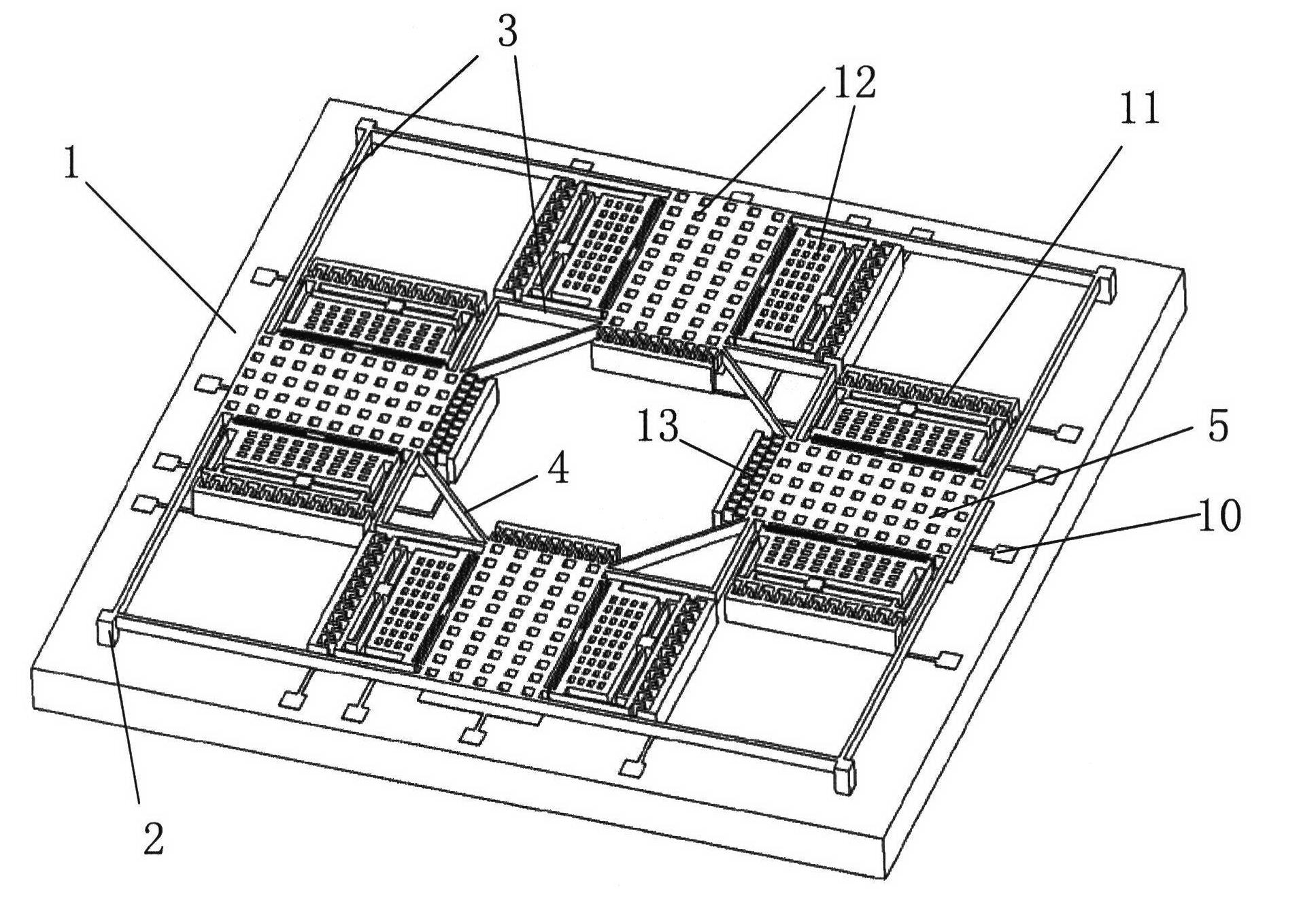

[0024] Such as figure 1 Shown is a three-dimensional structural schematic diagram of a single-structure micromechanical three-axis gyroscope of the present invention. The three-axis gyroscope includes a substrate 1 and a gyroscope structure 2 fixedly placed on the substrate 1. The gyroscope structure 2 is located at the center of the substrate 1. The gyroscope Instrument structure 2 is a through-hole structure in the middle, including plane detection units and z-axis detection units, which are distributed on the periphery of the structure layer and symmetrically distributed along the x-axis and y-axis directions.

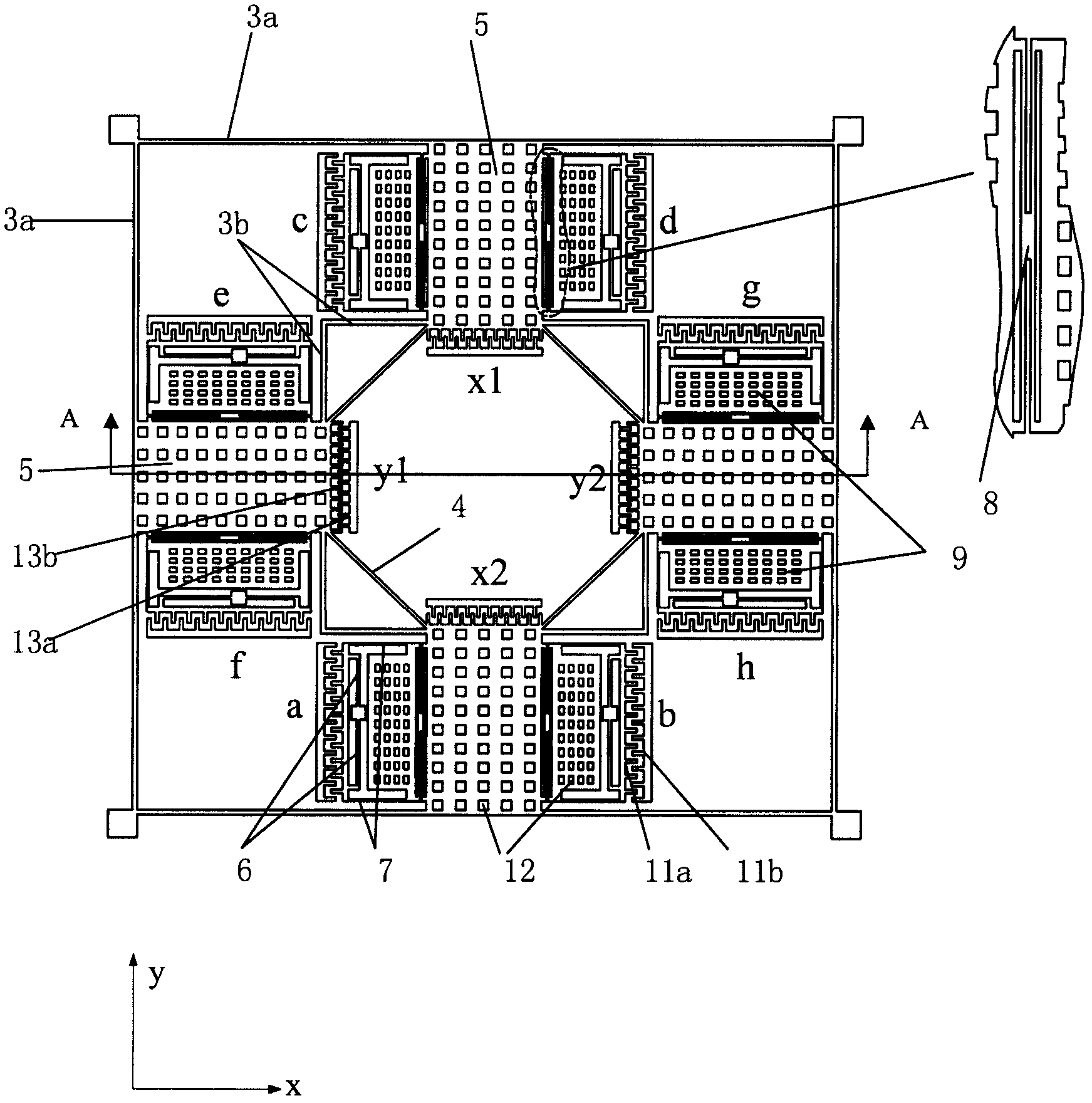

[0025] Such as figure 2 Shown is a schematic diagram of the structural layer of the single-structure micromachined three-axis gyroscope of the present invention. It can be seen from the figure that the plane detection unit includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com