Triangular encapsulation method of fiber grating sensor

A technology of fiber grating and packaging method, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low sensitivity, achieve the effect of improving temperature sensitivity, increasing temperature sensitivity, and eliminating cross-sensitivity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

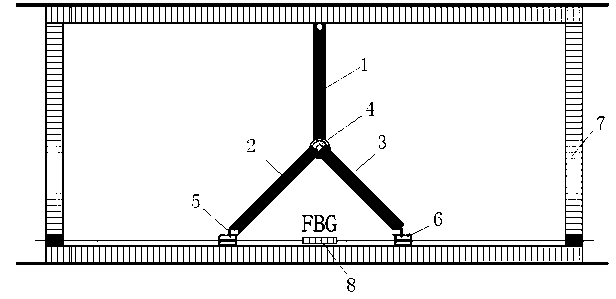

Method used

Image

Examples

Embodiment Construction

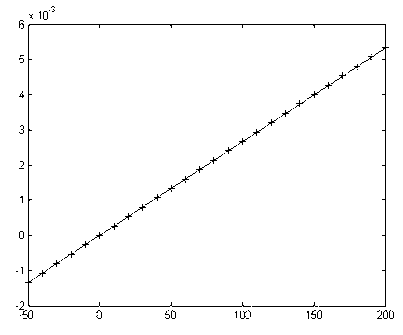

[0025] If all three arms of the present invention adopt aluminum alloy (its coefficient of thermal expansion is in Nearby), using formula 4 and formula 5 to calculate the relationship between strain and temperature change, the results are as follows figure 1 As shown, the abscissa is the temperature change, the ordinate is the strain change, the continuous line is the exact result obtained according to formula 4, and the × point is the approximate result calculated by formula 5, the two are basically consistent; figure 1 It can be seen that the linear coefficient of strain and temperature of fiber grating can reach 26 , while the strain and temperature compensation coefficient of this temperature-sensitizing type currently on the market is only 16 about. The abscissa is the magnitude of the temperature change, in degrees Celsius. The longitudinal coordinate is the strain amount of the fiber grating. It can be seen from the figure that the strain change effect of the fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com