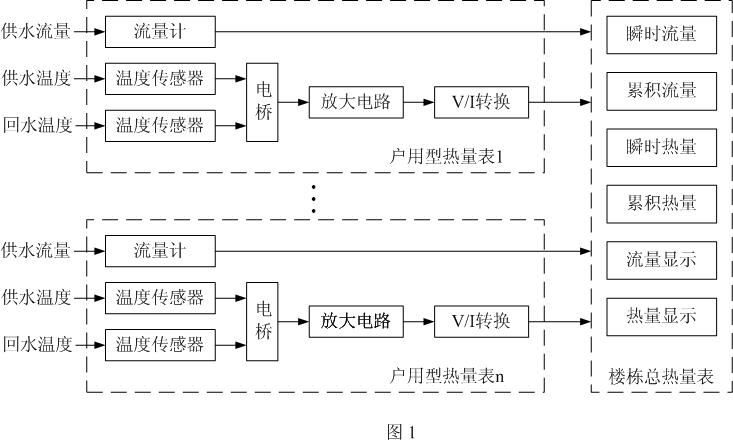

Heat meter based on movable Venturi pipe flowmeter

A Venturi tube and flowmeter technology, applied in the field of heat meters based on moving Venturi tube flowmeters, can solve the problems of mechanical flowmeters or differential pressure flowmeters, slow promotion, weak water treatment links, etc., and achieve The effect of small flow resistance loss, high measurement accuracy and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

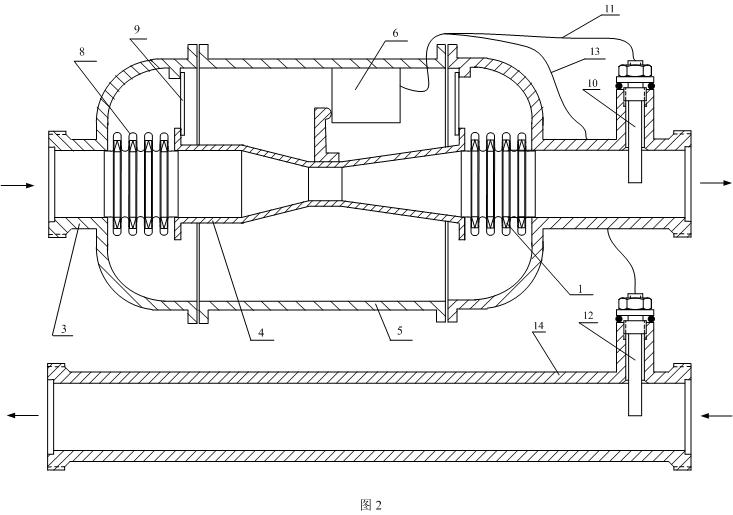

Embodiment 1

[0017] exist figure 2In the embodiment, the flow meter in the heat meter uses two U-shaped bellows 8, the front end of the front bellows 8 is in sealing connection with the front end pipe 3, and its rear end is in sealing connection with the inlet of the Venturi tube 4; The front end of the bellows 8 is in sealing connection with the outlet of the Venturi tube 4, and its rear end is in sealing connection with the rear end pipe 3. Fill the flexible filter medium 1 in each single-wave space in the front and rear bellows 8, which is larger than the caliber of the bellows 8, and the measured liquid can reach, forming a ring in each single-wave space Shaped filter layer. Each single-wave filter layer follows the front and rear expansion and contraction of the bellows 8 to perform corresponding axial expansion and contraction to ensure that hot water can only enter and exit the above-mentioned single-wave gaps through each single-wave filter layer. Because the front and rear disp...

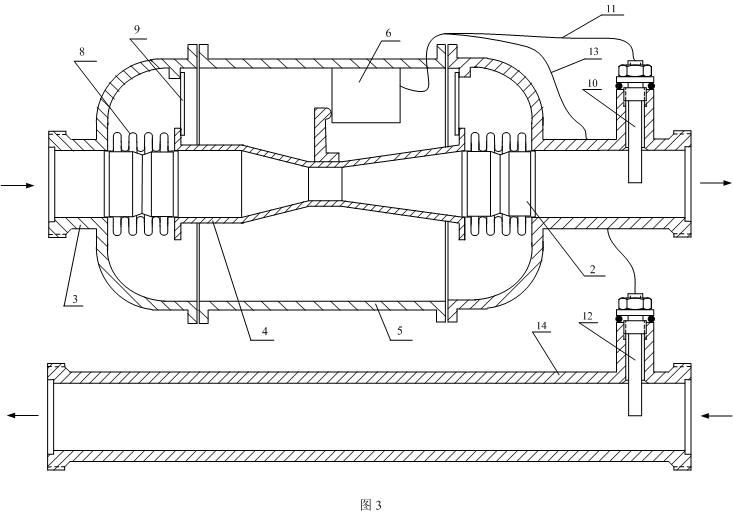

Embodiment 2

[0048] exist image 3 In the embodiment, it can be seen that the structure of this embodiment is roughly the same as figure 2 The first embodiment is the same, except that the flexible filter medium 1 is not filled in the gaps that can be reached by the measured liquid inside each single wave in the front and rear bellows 8, which is larger than the inner diameter of the bellows 8, but uses Two cylindrical filter membranes 2 with the same caliber as the inner diameter of the bellows 8 are provided, and each filter membrane 2 closes the gaps accessible to hot water larger than the caliber of the bellows 8 inside all single waves in the bellows 8, and filters Diaphragm 2 can follow the axial expansion and contraction of bellows 8 to do the same axial expansion and contraction, so that hot water can enter and exit the above-mentioned single-wave gaps of bellows 8 only through this filter membrane 2 . The cylindrical filter membrane 2 can be made of ordinary fiber fabric, or an ...

Embodiment 3

[0050] exist Figure 4 In the embodiment, the two ends of the moving Venturi tube 4 are each fitted with a ring-shaped corrugated elastic diaphragm 7 with corrugated edges, and the inner edges of the front elastic diaphragm 7 and the rear elastic diaphragm 7 are respectively connected to the venturi. The inlet and outlet of the inner pipe 4 are sealed and connected, and the outer edges of the front elastic diaphragm 7 and the rear elastic diaphragm 7 are sealed and connected with the front end pipe 3 and the rear end pipe 3 respectively. The casing 5 is rigidly connected with the front end pipe 3 and the rear end pipe 3, so the distance between the two end pipes 3 can be fixed, and other components can be installed thereon. The gap between the elastic diaphragm 7 and the end pipe 3 is filled with a flexible filter medium 1 to form two ring-shaped filter layers. The filter layer can follow the movement of the Venturi tube 4 to perform corresponding axial expansion and contracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com